Difference Between Hopper And Crusher

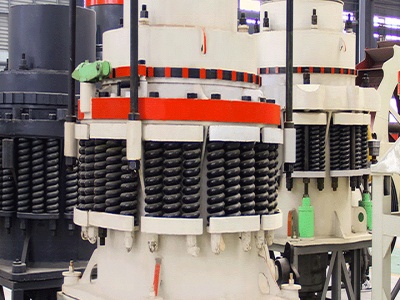

Symons Cone Crusher

For finer crushing or reduction a Symons cone crusher the norm. Symons are commonly used for secondary, tertiary or quaternary crushing. They do this by a different chamber design which is flatter and by operating at about twice the rotational speed of a primary type gyratory crusher. One of the first cone crushers had a direct drive vertical motor mounted above the spider with the drive shaft ...

What Are The Differences Between Single And Double Toggle ...

Jan 09, 2015 · The crushing process happens, when the feed material between the two jaws is compressed. Another difference between the double toggle jaw crushers and the single ones, is the position of the eccentric. In a double jaw crusher, the eccentric is found behind the swinging jaw. That helps protect the eccentric from any further damages.

3 Differences between One and Two Shaft Shredder

Dec 02, 2020 · Single Shaft Shredder is equipped with only one shaft welded with rotary blades. The rotor a hydraulicactuated pusher arm. and a screen underneath the rotating shaft. Double Shaft Shredder is built with two shafts of blades, which we also call dual shearing shafts. Its rotor consists of multiple disks of blades. The 2 rotors counterrorate.

The Difference Between A SemiAutomatic And Fully ...

Dec 20, 2016 · The primary differences in between the semiautomatic and also the full automatic concretebatching plant are to do with the controlsystem, even though the other equipment will have no differences. The fullyautomatic control systems utilize a fullautomatic control system while the semiautomatic control system utilizes a centralized controlsystem.

Difference Between Portable Moveable CrusherCrusher

The Differences Between Semiportable Crusher And. In order to enhance the maneuverability of the crusher machine the portable rock crusher is designed and developed in combination with market demand a portable rock crusher can be used for crushing rock ore block road asphalt concrete construction waste and other materials the portable rock crusher is mainly divided into the .

Compare Gyratory Crusher vs Jaw Crusher

Jul 18, 2015 · Because of this difference each type of crusher has its own environment that it operates best or at least better in, than the other. As an example, a gyratory crusher can be fed from two sides and handle ore that tends to slab. Also its design allows a higher speed motor with a high reduction ratio between the motor and the crushing surface.

Gyratory and Cone Crusher

Jan 01, 2016 · Primary crushers are solidly built to receive large lumps of rock directly from the mines and designed for large tonnage throughputs. Basically, gyratory crushers consist of a fixed solid conical shell or bowl (also called concaves) and a solid cone within the bowl called a breaking head (Figure ).The breaking head is fixed to a central spindle, which is hydraulically suspended or ...

Plastic Auto Loader

Contact Us. Contact: Lizzie. Phone: +. Tel: +. Email: sales Add: Zhentou district,Liuyang city,Hunan 410319

Reimagining a tired design

Aug 07, 2018 · There was one key difference between the old tire wall and the new wall: the new wall's face would include a vertical portion around the pocket where the crusher's steel hopper would be inserted. The rest of the new wall's face, like its predecessor, would have a battered, or receding, slope.

What's The Difference Between a Lump Breaker and a ...

Feb 04, 2020 · Key Differences Between a Lump Breaker and a Hammermill. As we've already mentioned, a hammermill will break down more solid materials than a lump breaker. Lump breakers use a lower impact force and larger operating clearances between the blades and the breaker bars. This means they are ideal when a gentle granulation, coarse size reduction ...

Crushing Plant: Surge Bins VS Stockpiles

Feb 29, 2016 · Crushing Plant: Surge Bins VS Stockpiles. I need to further comment on the influence of surge storage upon plant operation. The provision of adequate surge storage at the right places in the flow line is of sufficient importance to warrant a little further consideration. It is desirable, in the crushing plant, as it is in any production process ...

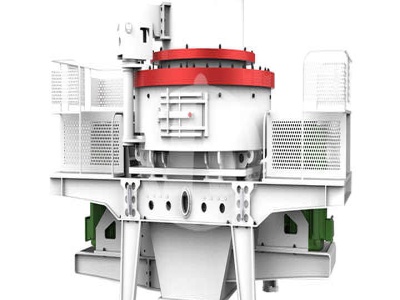

Impact crusher vs. Cone Crusher | X vs Y

Aug 05, 2014 · The impact crusher is composed of an impact plate, a board hammer, a rotor, a feed hopper and few insignificant parts. The working principle of the impact crusher is very simple: the material is thrown to the impact plate and crushed until it can .

DIFFERENCES BETWEEN HAMMERMILL AND OTHER MILL | Crusher .

difference between impact and hammer mill – Crusher South Africa. difference between hammer mill and impact . Impact is the primary force used in a hammermill. . For more information on this or any other our machinery .

Vacuum Auto Loader

Product description: Vacuum Auto CUMOND fullautomatic suction machine,a kind of auxillary equipment,can be together with kind of plastic machines and heatwind drying international advanced technology,it is made of stainlesssteel,saving labour and ensuring safe feeding has alarm design ...

What Is The Difference Between Quarry Dust And Crusher Dust

For a 700 TPH quarry, that's about seven tons per hour lost from conveyors, crushers and screens, and that does not include loses from difference in selections between an effective and ineffective dust collector is often much narrower than in many other industries. Read more.

star trek

Feb 26, 2016 · Adm Grace Hopper was mentioned in another answer. Her speciality was computers. Starfleet ranks are modeled on the ranks in the US Navy, as another answer said. Commander in the USN is the equivalent of Lt. Colonel in the US Army. In the Army, Commander Crusher would be Lt. Colonel Crusher.

The difference between DISC MILL and Hammer MILL_Hebei ...

The difference between DISC MILL and Hammer MILL. DISC MILL: crush materials via the interaction of pin inside,The helicoidal surfaces are produced mostly by form cutting with forming cutters of end mill type, side mill type or disc disc mill, is a type of crusher that can be used to grind, cut, shear, shred, fiberize, pulverize, granulate, crack, rub, curl, fluff, twist, hull, blend ...

difference between cs and ch cone crusher

difference between cs and ch cone crusher. Short head cs cone crusher capacity chart. Cone Crusher An Overview ScienceDirect Topics . The cone crusher is therefore an excellent arrested crusher The flare of the bowl allows a much greater head angle than in the gyratory crusher while retaining the same angle between the crushing members This gives the cone crusher a high capacity since the ...

Diagnostics of cone crusher feed segregation using power ...

Oct 01, 2018 · In both tests, there is a difference between the variance over the crusher geometry which would result in the histogram seen in Fig. 7B. That is, on one side (around 240 degrees), all the lines or the power draws are at approximately the same level but on the opposite side, the variance is significantly higher between crusher revolutions.

Apron Feeders

May 31, 2016 · A jaw crusher fed with an Apron feeder will increase capacity upto 40% by eliminating bridging and supplying a steady even feed. Photo shows shop assembly of a 24" x 36" Traylor Type M Jaw Crusher and a 36" x 12'0" Traylor AllSteel Heavy Duty Apron Feeder. The Type M Crusher is built with a 50,000 pound TENSILE STRENGTH Meehanite Frame, with pitman shaft bearings fitted with ...

EPA2

A method and apparatus for controlling the operation of a rock crusher and feeder such that the rate of supply by the feeder to the crusher hopper is kept within carefully controlled parameters and such that the power level at which the crusher operates is maintained within a narrow range at the optimum operating range of the rock crusher.

Latest Posts

- مهندس التصميم الميكانيكي

- الهند الفحم محطم تقارير حالة

- حساب مؤسسة مختبر كسارة الفك

- الدولوميت التفاعل

- باكستان ماليزيا صانع الطين سحق آلية

- مشروع قانون من مادة محطم

- كسارات وطحن للبيع في ماليزيا

- الهند حجر الرحى

- تأجير الحديد الرمال آلة شفط

- شراء تستخدم كسارات الفك أستراليا

- كسارات الفك المصنوعة في إيطاليا

- بالموجات فوق الصوتية الاهتزاز غربال مسحوق رقيق

- التعدين الصحافة

- الأبحاث المتعلقة ب مصنع حجر محطم مختبر المحمولة

- Low Budget Artificial Sand Making Unit In Southern State Of

- Apakah Ball Mill Efisien Energi

- To Buy Small Jaw Crusher

- C S Bell Grist Mill Sales Grinding Mill Vertical

- China Crushers Brazil Office Address

- Differene Between Crusher And Pulverizer

- Stone Crusher Grinding Mill Manufactuers At China

- Obuasi Gold Mine Address

- Cement Bricks Plant In Rwanda Price

- Mills Equipment In Libya

- Lime Kiln Technology

- Used Animal Feed Pellets Plant For Sale In Italy

- Crusher Feeder Le In South Africa

- Limestone Crusher Rollerlimestone Crusher

- Mill For Ferrous And

- Cement Mills 26amp 3b Clean Product