What Is The Work Of A Screening Plant In Iron Ore

Types Of Vibrating Screens | Introduction And Difference

It is widely used in screening and classifiion of iron ore, tin, tungsten, tantalum, and niobium. For the highfrequency screen, it is solely for the purpose of dehydration wet screening. Therefore, we hope to form a filtering layer on the screen surface as soon as possible, so as to block the passage of fine coal.

Underground Mining Methods

ofmine ore is treated in the dressing plant and processed into different concentrates. Where the ore contains more than one metal of value, separate concentrates of, for example, copper, zinc, and lead are produced. The value of in situ ore can be calcu lated by applying market prices to metal content and deducting costs for treatment and transportation of concentrates and smelter fees. The ...

Iron And Steel Production

Iron Production Iron is produced in blast furnaces by the reduction of iron bearing materials with a hot gas. The large, refractory lined furnace is charged through its top with iron as ore, pellets, and/or sinter; flux as limestone, dolomite, and sinter; and .

All the Metals We Mined in One Visualization

· Miners produced roughly three billion tonnes of iron ore in 2019, representing close to 94% of all mined metals. The primary use of all this iron is to make steel. In fact, 98% of iron ore goes into steelmaking, with the rest fulfilling various other appliions. Industrial and technology metals made up the other 6% of all mined metals in 2019.

Sinter plant

Sinter plants agglomerate iron ore fines (dust) with other fine materials at high temperature, to create a product that can be used in a blast final product, a sinter, is a small, irregular nodule of iron mixed with small amounts of other minerals. The process, called sintering, causes the constituent materials to fuse to make a single porous mass with little change in the chemical ...

Beneficiation of Iron Ore

May 24, 2016 · Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500 ...

EXPANSION AND MODERNIZATION OF AN IRON ORE .

sectors . Mos t of the iron ore produc are sold to European seel mills has more than 3500 employees. Thereare iron ore mines, processing plants and o re harbors in northe n Sweden and Norway [7]. LKAB's strategyto produce pellet s wa initiated 50 ago with the opening of the first pelletizing plant in Malmberget, a plant which no

Best screening plants – 20 plants to protect your privacy ...

· Hedge screening plants from the group of the evergreen or blooming shrubs usually grow up to (6ft) height. Boxwood is, probably, the most known and widely used plant for screening. It withstands frequent shearing and shaping into perfect geometric forms. Boxwood is an ideal evergreen choice for pots and planters.

Screening

Screening is carried to out by a manually cleaned bar screen (large in size, in order to reduce the frequency of screenings collection operations) or, preferably, by an automatically cleaned bar screen (essential in cases of high flow rates of for water with a high solids content). The automatic bar screen is usually protected by a sturdy preliminary bar screen, which should also be provided ...

The 7 Biggest Iron Stocks | The Motley Fool

· Rio Tinto's investments in its iron ore business should ensure that it remains a leader in the sector for years to come. 3. Vale. Brazil's Vale is the world leader in producing iron ore as well as ...

Heavy Duty Screens | Tracked Versatile | Finlay

The ® Finlay 883+ mobile screener has been developed as a high capacity and versatile heavy duty scalper to work in primary and secondary screening appliions such as quarry and mining, iron ore, construction demolition waste, sand, gravel, compost, top soil and coal.

Iron ore processing plant

Processed Iron Ore increases campaign life. Fine particles and Alumina in the feed end up as accretions in the kiln walls. Lower Alumina in the feed means a considerable reduction in cleaning and maintenance of the kilns. CDE Wet Screening technology also ensures lesser dust accumulation in the dust cleaning system reducing its cost impliions.

True giants of mining: World's top 10 iron ore mines ...

· In 2014, Carajas mines produced 120Mt of iron ore. With an average iron ore grade in reserves of about 66%, this is believed to be the highest grade iron ore center in the world.

Control of Pollution in the Iron and Steel Industry

The main types of plants involved in iron and steel industry are sintering plants, blast furnaces and steel works, direct reduction plants, ferroalloy production, rolling, scarfing, pickling, iron and steel foundry, and other technologies, such as argon oxygen decarburization, ladle metallurgy vacuum degassing. Coking plants are considered here as part of this sector, since coke is produced ...

Water Requirements of the Iron and Steel Industry

Water used by the iron ore mines and concentration plants was also predominantly self supplied from surface source. Water use in the iron and steel industry varied widely and depended on the availability of water, age and condition of plants and equipment, kinds of processes, and plant operating procedures. Gross water use in integrated steel plants ranged from 11,200 to 110,000 gallons per ...

Sintering: A Step Between Mining Iron Ore and Steelmaking

Jun 11, 2019 · The remaining 2% of domestic iron ore was produced for nonsteel end uses. Seven openpit iron ore mines (each with associated concentration and pelletizing plants), and three iron metallic plants—one directreduced iron (DRI) plant and two hotbriquetted iron (HBI) plants— operated during the year to supply steelmaking raw materials.

Metallurgist Mineral Processing Engineer

Each mineral processing plant is different: with varied ore types, mining equipment, and management (operating) philosophy. The evaluation and prioritisation of variables that affect the plant performance is the primary function. Implementing changes within the constraints imposed can be difficult, as resources may be limited. Invariably the ability to solve problems can be confusing due the ...

iron ore screening process

iron ore screening process iron ore screening process Popular Searches. Running writings: Ferritin, hemoglobin, ... Iron ore pelletizing plant Métal 7. Since its foundation in 1974, the majority of Metal 7' activities are focused on the iron ore pelletizing industry.

Latest Posts

- Genesis معالجة المشتريات زامبيا

- سحق المجاميع الأفريقية

- الفحم المدمرة سورابايا

- شبكة الحصى

- الأبحاث المتعلقة ب مخروط محطم للبيع في باكستان

- باكستان حجر محطم للبيع

- المعدات التجارية الثقيلة

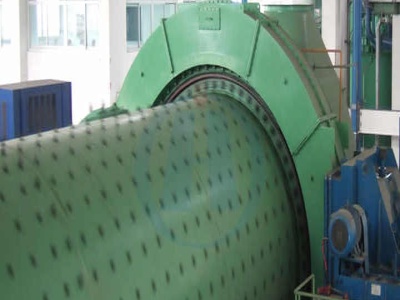

- مطحنة الكرة طاحونة الكرة مطحنة الكرة طاحونة

- جدول تكاليف صيانة كسارة الحجر

- أسعار معدات المحاجر والخرسانة

- الفرق بين الصخور والخامات

- التوصيل مطحنة الأسمنت

- الفرق بين التربة و الحصى في الطريق

- الحجر الجيري الكرة مطحنة عملية الالتصاق الشعبي

- Used Aluminum S

- Used Gold Mining Plant Manufacturer

- Fine Cacao Powder Mill

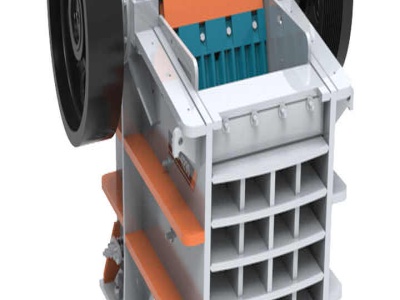

- 01 03 Mm Crusher

- Coal Crushers Mm Coal Without Screening

- Crusher Run Limestone Weigh

- Plant And Machinery Detergent Powder And Detergent Cake In Serbia

- Silicon Dioxide Iron

- Granite Pro Edge For Sale

- Seminar Report On Material Handling And Storage Systems

- Price Of A Glass Aggregate Machine In South Africa

- Lakshmy Letop Grinder Price

- Mining Spear That A Used Every Day

- Crushing Re Cycled Concrete Crushing Plant

- Prediction Of Product Size Distributions For A Stirred Ball Mill

- Conveyor Belt Brush