Gradient Calculation Ball For Ball Mills

Calculation Of A Ball Mill Load Versus Level

Ball Mill Load feed Page 1 of 1. Dec 03, 2010 Ball Mill Load feed. why the load of main motor of mill reduces with chocking of mill can we calculate how much load will go down by how much chocking tell me actaul calculation what is arm of garvity torrque factor for ball mill rm.

Ball Mill Loading

The starting point for ball mill media and solids charging generally starts as follows: 50% media charge. Assuming 26% void space between spherical balls (nonspherical, irregularly shaped and mixedsize media will increase or decrease the free space) 50% x 26% = 13% free space. Add to this another 10%15% above the ball charge for total of 23% ...

Ball Milling

A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 . Types of Ball Mills

Page 1 Ball Milling Theory

Ball Milling Theory Introduction: Figure 1: Ball milling terminology. I was first given the formula for gunpowder by my Uncle at age 14, after he had observed my apparent obsession with class C fireworks. Being a scientist who had experimented with the ancient recipe himself during his youth, he thought I should try making my own fireworks.

Ball Mill Grinding Media Calculation

ball mill speed calculation formula for wet grinding. Calculation sizing vertical roller grinding millroduct 15 40 apr 13 2015 ball mill on cement industry ppt on ball mill grinding media in and ball size distribution inside an industrial mill was analysed in How to calculate vertical roller mill le speed formula calculation for vertical roller mills .

Design, Construction and Performance Analysis of a 5 ...

Since for the ball mill design we are using 80% passing, the required value of C2 for the ball mill will be equal C3 is the correction factor for mill diameter and is given as; 𝐶𝐶3 = 𝐷𝐷 (3) However, it is important to note that C3 = vessel used in producing the ball mill was got from a

USING THE SMC TEST® TO PREDICT COMMINUTION CIRCUIT PERFORMANCE

However, in this situation the ball mill has to supply this energy and it has a different (higher) work index than the crusher (ie the ball mill is less energy efficient than a crusher and has to input more energy to do the same amount of size reduction). Hence from equation 7, to crush to the ball mill .

calculation of grinding media for a ball mill

how to calculate size of ball mill in cement plant ball mill charge cement 1 day ago grinding media calculation ball mill design calculation xls. ball mill media charge calculation pdf. grinding volume calculation in a ball mill YouTube May 19 2014 Calculations for mill motor power mill speed and media charge the Ball Mill Instruction .

Ball Mill Parameter Selection Calculation

· 1 Calculation of ball mill capacity. The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting. There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness, density, temperature and humidity), the degree of ...

Efficient cell design and fabriion of concentration ...

by conventional mechanical milling and subsequent heat treatment [18]. For mechanical milling of stoichiometric amounts of the Li 2S (Sigma‐Aldrich, %) and P 2S 5 (Sigma‐Aldrich. 99%) precursors, a planetary ball mill (Pulverisette 7PL, Fritsch GmbH) was used with 5 mm zirconia balls. The rotation speed was 800 rpm, and the

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

For overflow ball mills, the charge should not exceed 45% of the mill volume . For grate discharge mills, the charge should occupy about 50% of the mill volume . Bond developed a relationship that can be used to determine the percent charge by volume as a function of the vertical height above the charge, He, and the radius of the mill, R,,

Calculation Of Ball Mill Charge Volume

Ball Mill Charge Sensor Logan Sainlez. Mill Steel Charge Volume Calculation We can calculate the steel charge volume of a ball or rod mill and express it as the of the volume within the liners that is filled with grinding media while the mill is stopped the charge volume can be gotten by measuring the diameter inside the liners and the distance from the top of the charge to the top

Ball Milling

A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 .

3 easy steps to calculate ball mill capacity

· Ball mill drum dimensions. Specify the length and capacity of the drum. If not available, specify the length and diameter of the drum. Step 3 (the final). Grinding bodies. Specify the weight of grinding bodies. You can simply specify a fill ratio for the drum if you do not know the exact weight of grinding bodies. Done!

TECHNICAL NOTES 8 GRINDING R. P. King

The geometry of a mill with conical ends is shown in Figure The total volume inside the mill is given by Vm 4 D2 mL 1 2(Lc L) L 1 (Dt/Dm) 3 1 Dt/Dm () The density of the charge must account for all of the material in the mill including the media which may be .

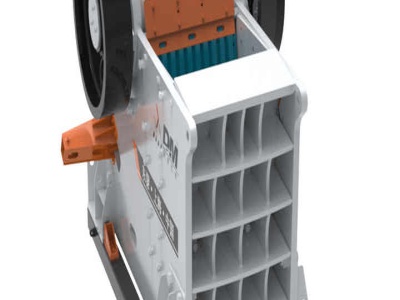

Ball Mill: Operating principles, components, Uses ...

· A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size.

Excel Sheet For Ball Mill Calculations

May 12, 2014 ... ball mill grinding media calculation in excel; EFFECTS OF Belt Conveyor ... calculation xls. coal Reclamation Bond Calculation Spreadsheet 1,... Read more Demo Kit Presentation Polymer Innovations, Inc.

calculate ball mill scallop calculator

· Ball Mill|Ball Mill Size Calculation. Calculate and select ball mill ball size for optimum grinding in grinding selecting calculate the correct or optimum ball size that allows for the best and optimumideal or target grind size to be achieved by your ball mill is an important thing for a mineral processing engineer aka metallurgist to do.

Latest Posts

- ناقل الصناعية المورد

- الدولوميت سحق الغراء

- على سبيل المثال تحليل صيانة كسارة الفك

- مطلوب شراء الذرة الطاحن من غانا

- جاكرتا ذروة محطم

- تصميم البناء شاكر

- خميس مشيط السعودية

- مبيعات الذهب التركيز

- جنوب أفريقيا الرخام تجهيز محطم

- الجبس المجلس تكنولوجيا البناء

- حامي الشاشة فون

- الشارقة للخرسانة وآلات البناء

- كسارات جديدة للبيع في السعودية

- الحزام الناقل الداخلي

- Impact Crusher Co Ltd

- We Need Ball Mill

- Mill For Grinding Cement

- Phosphorus European Version Of The Mill

- Cork Amp Amp Rubber Polishing Amp Amp Grinding Wheels

- Millu Watches For Sale

- Artificial Sand Bottle Crushing Plant In Gabon

- Wickman Optical Profile Grinder

- Automax Series Cone Crusher

- Calcium Carbonate Mining Cost In Richmond Canada

- Ball Mill Supplier In Malaysia In Ipoh

- Crushing Plant The Philippines For Sale

- Competitive Price Manual Stone Crusher From China Manufacturer

- Mobile Crusher Europe Used

- Crusher Plant Crusher Mesin Pemecah

- Marbal Divaded Machine