Raw Mill In Cement Fuctory

raw

what is raw mill in cement fuctory; what is stone crusher raw material; how vertical raw mill work; Website Sections minerales se llevaron espanoles america; aggregate crushing operation mesin milling kecil; crawler mobile screen station in switzerland; chromium ore flotation price principle ; pe jaw crusher in bahrain; crusher which brand is good; combustor of rotary kiln in argentina; cone ...

Raw Mix Preparation

• Raw mill control • Closed loop control of feeder set points • Cost minimization • Constraint satisfaction • Human Machine Interface • Latest web technology: serverthin client architecture • Basic set of standard reports, process displays, trends and menus OptimizeIT is an outstanding robust solution for quality issues at the cement plant. It puts the most modern software and ...

what is raw mill in cement factory

Raw Material Preparation Cement Plants and Kilns in Britain and . The traditional motive power for the process was from water or wind. It is interesting to note that when James Parker commenced making his "Roman" Cement, he set up at Northfleet, not for reasons of raw materials or market, but because a water mill was available.

Cement Plant, Cement Equipment | Cement Plant Manufacturer ...

Cement plant is necessary for cement production, mainly consist of a series of cement equipment apply for preparation of cement raw materials, clinker production, and finished cement production, such as cement mill, cement crusher, rotary kiln, cement roller press, cement dryer, clinker cooler, cement silo, and related cement plant equipment.

Rawmill

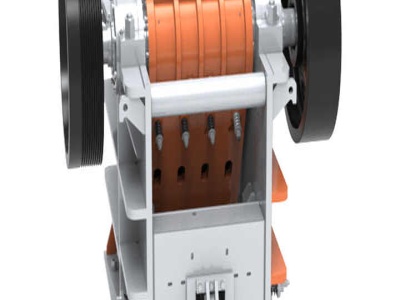

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the ...

raw mill function in cement factory

Raw Mill Feeding Cement Plant Optimization. IIn the value stream map of cement manufacturing the raw mill feeding is an intermediate activity between prehomogenization and raw milling, and has not been discussed separately by most of the authors however, in my opinion it remains and must remain as of pivotal importance, so far as the quality assurance is considered

Cement plant in Russia have WEG solution applied to raw mill

· A WEG motor will drive the raw material mill of a cement plant in Russia. Reliability and low maintenance! This is what customers are looking for when choosing a WEG product. Novoroscement, a cement company loed in Russia, needed higher plant reliability and less maintenance costs. Thanks to WEG specialists the whole case scenario was taken ...

replacing mills in cement factory

Gearbox of raw mill cement factory. Cement mill in cement factory fruitfantaisiech Cement Kilns Ketton The point of entry of the raw materials on to the site is shown in the left top corner of Fig 2 The clay wagons are taken along the rails nearest the factory and the clay is discharged directly from the wagons into a wash mill which is of the ...

Working Of Raw Mill In Cement PlantHN Mining Machinery ...

Raw mill is mainly used in grinding raw materials and end products in cement plant. It is also suitable for various ores and other materials metallurgy, mine, chemical and construction. Besides, it has two forms of milling, one is an open form, and the other is a .

Raw Mill Structure In Cement Factory

Raw Mill Structure In Cement Factory. Raw mill analysis on cement factory the energy exergy and exergoeconomic analysis of a cement factory has been studied within two partshis paper is the first part of the study which includes the thermodynamic and exergoeconomic methodology and formulations developed for such a comprehensive and detailed analysis

About Raw Mill In Cement Factory

Cement Factory Raw Mill. View Vertical Raw Mill for Cement Raw Meal Grinding in Cement from MECHANICAL 411 at University of Sargodha, Sargodha. Home About Product Center Solutions Appliion Contact 16, 2015 Mill designs. The most important first step in controlling energy consumption is to be aware of the relative importance of the process areas where most energy .

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement ...

The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; 1. Quarrying and Crushing 2. Raw material Storage and Transportation 3. Proportioning 4. Raw material Grinding and Transportation 5. Raw meal storage, homogenization ...

what is raw mill in cement fuctory

Raw mill is mainly used for grinding raw materials in cement plant and is also suitable for grinding mineral ore and other materials in metallurgy, chemical, power plant it can work in open circuit or closed circuit with separator raw mill has features of various materials appliion, continuous running, big grinding rate, easy control of product fineness

raw mill structure in cement factory

raw mill structure in cement factory These components are rarely found in one type of raw material therefore for the cement production the raw mix is selected for the following components carbonate component rich in calx is contained in the raw mix in a quantity of limestone mohs hardness is the older the geological fraction the firmer... raw mill analysis on cement factory Know More ...

Cement mills and raw mills for high throughput rates

High throughput rates, permanent plant availability, ... cement raw material, cement clinker or granulated blastfurnace slag – and how different their grindability and abrasiveness may be, the MVR mill ensures throughput rates of a different dimension, around the clock, reliably and on the long term. Forget about downtime. With Pfeiffer you will grind on a grand scale. Advantages of the ...

What Is Raw Mill In Cement Fuctory

What Is Raw Mill In Cement Factory Popular Eduion . In this study, the raw mill of a cement plant is considered and its performance based on the first and second laws of thermodynamics is read more. chapter introduction to cement production. these materials are more properly known as hydraulic cements. gypsum plaster of portland cement. the mixture of materials is finely ground in a

raw mill structure in cement factory

raw mill analysis on cement factory. raw mill analysis on cement factory For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more price

Cement Factory Raw Mill

Raw Mill In Cement Plant,Cement Making PlantThis paper mainly introduces the raw mill in cement plant. In order to achieve the desired setting qualities in the. Get Price; Cement Process Energy Saving Eccj. Cement Process Energy Saving October, 2006 The Energy Conservation Center, Japan Taichiro Kawase. Laos 2 Water Layout of one Japanese cement factory Waste tire yard Coal yard ...

Raw Mill In Cement Fuctory

Raw Mill – Kiln Appliion In Cement Industry Thermax. Like in any cement plant, the Bag House operates in two basic modes of operation Compound Mode Of Operation – Here the Raw Mill is in running condition, therefore major part of Preheater exit gases will be routed through the Raw Mill circuit( including Raw mill,.Jan 19, 2014 Raw mill Blending Of Raw Meal 30 31.

Latest Posts

- الفلبين ملموسة محطم

- استشعار الاهتزاز طاحونة الخام

- مصغرة المحمولة كسارة الفك الابتدائي المحاجر PE 400

- الاستواء الذاتي المحمول الزاحف محطم

- الكالسيت طحن خط

- أفضل عينة في اللغة الإنجليزية ورقة المواصفات

- الصين مصنع شاشة مصنع الغسيل

- مصنع الاسمنت آلات مصنع الاسمنت تكلفة المشروع

- معدات سحق الحجارة الثقيلة قطر

- مصر المعادن والخامات

- محطم القديمة للبيع في أوروبا

- تطبيق مطحنة خام خلع الملابس

- بيع العقيق الفك محطم

- السودان المعادن النادرة الأرض ماكينات تعدين ومناجم

- Prices For Diamond Pan Washing Plants

- Used Australia Mining Quarry Crusher

- Buggenum Loesche Mills Power Consumption

- Buy Fluorite Stainless

- Copper Flotation Cost

- Crusher Daur Ulang Beton Di Tempat

- Stone Crusher Selling Various Types

- Small Asphalt Grinding Equipment Manufacturer Canada

- 1900 Tons Of Hanging Roller Powder Stone Machine

- Block Making Machine Exporter Manufacturer

- Godrej Grinder Machine

- Fertilizer Mill Plant For Sale

- Artificial Sand Cone Crusher Manufacturer

- Quartz Grinding Plant In Philippines

- Used Portable Or Mini Cone Crusher

- Surplus Rubber Roll Mill