Cement Vertical Mill Transmission Msx

Fundamentals, Selection, Installation and Maintenance of ...

5 Fundamentals, Selection, Installation and Maintenance of Gearboxes Part 2 Note: Most manufacturers' gearboxes are test run with breakin oil that contains rust preventive which will protect the internal parts for six months under normal storage conditions after they

coal mill to boiler animation flash

Nov 17, #; 2Coal pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill The pulverized coal and air mixture is then transport to the boiler burner.

Cement | FUCHS LUBRITECH

Vertical mills separator bearings, gearboxes Separator bearings of vertical mills face a critical combination of load, revolutions, and size. In addition, they are positioned in the airstream and thus heavily exposed to increased temperatures and dust. URETHYN MP 2 was especially developed to lubrie these bearings. It provides a good pumpability and guarantees excellent lubricity under ...

cement vertical mill transmission msx

cement vertical mill transmission msx . our products. DQ Mining is a hightech company integrating RD, production and sales. It provides mature products and solutions such as crushers, sand making, milling equipment, mobile crushing stations, etc., for aggregate, mining and waste recycling.

VAID

A cement plant requires a huge quantity of gearbox for its machinery, such as vertical mill, cooling tower, bucket elevator, rotary kiln, crusher, separator, ball mill, conveyors and mixer, etc Cooling Tower Gear Box Gear boxes are used as speed reducers to slow the rotational speed from the incoming motor to the outgoing fan of a cooling tower.

Slag Mill | Vertical Slag Mill Provider | SINOMALY

Vertical Grinding Mill to make Blast Furnace Slag. SINOMALY has been developing and manufacturing Vertical Grinding Mill to make Blast Furnace Slags since 2007. This vertical slag mill can be installed in a slag powder production line with an output range from 45t/h to 300t/h. The structure of the slag grinding mill is similar to the cement ...

Home

INTERN TOOTHED GEAR WHEEL for Vertical Mill Drive Gear Unit. ... Cement Industry. JS90 JS90A JS90B JS90C Cement ball Mill Drive Spare Part Gearbox Gear Drive. gearbox001December 8, 2020 0. Cement Industry. MBY400 MBY4004 MBY4005 Ball Tube Mill Drive Spare Gearbox ... Gearbox001 is an professional media center for transmission ...

Home

Destruction of grains during mixing of lightweight concrete. The use of lightweight concrete for the production of bricks and prefabried parts is currently a major trend. The aggregates are offered in a range of grain sizes, and the amounts used in the recipes follow .

Ball Mill Power Transmission

cement vertical mill transmission msx | Cement production Ball mill The wellknown magazine Power Transmission World has recently released the article Roller, Technological and Tailormade .Besides, when used together with a ball mill, it can be used in .

Cementlime industry

AIUT designs, manufactures and delivers turnkey products, such as: lime kiln shaft furnace control systems. Maerz furnace control system. control and supply systems for horizontal and vertical cement mills. automatic sampling and pneumatic transmission to an automatic cement testing laboratory. cement laboratory automatic supply and control ...

Girth gear for rotary kiln and ball mill manufacturer ...

Girth gear for rotary kiln and ball mill manufacturer CHAENG The girth gear is the main component of the rotary kiln and the ball mill. It needs to drive the entire Cylinder to run. Therefore, in actual production, the quality requirements of the girth gear are very high.

Vertical Roller Mill, Vertical Roller Mill Wear Parts And ...

The vertical roller mill has become the preferred equipment for cement industry raw material grinding, is estimated to have more than 600 sets of production. Large vertical mill capacity has reached 600t/h, the transmission power of 5000KW. At the beginning of the 90's the mill in cement grinding and have new progress, there are many large ...

VERTICAL ROLLER MILL DRIVE GEARBOX | Elecon

Compact design suitable for high power transmission and capable of withstanding high loads due to grinding rollers. Technical Specifiions. B1PV 80 to B1PV 200. Product Appliion. Vertical Roller Mills for grinding in Coal, Raw and Cement. Range. B1PV 80 to .

Gearbox replacement on a vertical roller mill by Cementos ...

The first ones replaced the gearboxes of a horizontal cement mill and a horizontal raw mill in 1993. Both new gearboxes were of CPU type. The latest installation was a WPU type gear unit for another vertical raw mill in 2005. The highpressure pumps are among the critical components of the lubriion unit.

Cement mill gearbox,Cement mill gearbox,Cement mill gearbox

Gearbox for Cement industry is the core of transmission equipment in cement production system,including reducer for vertical roller mill,reducer for central drive tube mill,reducer for side drive tube mill,gearbox for unilateral double tube mill,planetary gearbox for rolling press and planetary gearbox for central drive tube mill,supporting the use of vertical mill,tube mill and roller press.

Home

· I agree to NGC Transmission Europe GmbH using and processing my personally identifiable information for the purpose of processing my request. I am aware that I have the right to revoke the processing of my data at any time with effect for the future. My request cannot be processed without my permission. For further details, please check our ...

Cement Plant

A "typical" cement kiln consisting of a raw mill section, a preheaterrotary kiln section, and a cement mill section was used to describe cement production in Germany. Using partitioning factors based on information from operating kilns, a mass balance model was developed for this "typical" kiln. Using this information, elemental distributions were calculated for cadmium, lead, and ...

Supplier SEW FA67 FA77 FA87 FA97 EURODRIVE gear units ...

Solid shaft, flange or foot mounting, can be used as the input stage part of multistage gearbox. Output speed: Output torque/power: 50Nm18,000 Nm/ kW. Reviews. There are no reviews yet. Be the first to review "Supplier SEW FA67 FA77 FA87 FA97 EURODRIVE gear units gearbox gearmotor reducer" Cancel reply. Your ...

KREBS® centrifugal slurry pumps

KREBS centrifugal slurry pumps are designed for heavyduty output, abrasive and corrosive duties, mill discharge, and highefficiency processes. Our pumps are used in hard rock, dredging, pulp and paper, and industrial operations all over the world. The key advantages of our slurry pump design are lower power requirements (up to 5% to 15% less ...

Latest Posts

- كسارة مباشرة

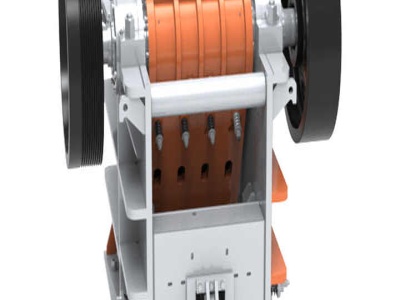

- كيان مخطط كسارة الفك

- تدابير السلامة في منجم الزنك

- جهاز تكسير الخبث في حيدر أباد

- الكوارتز التعدين

- ألف آلة الرد

- تأجير 60 طن محطم

- الهندي حجر سحق التكنولوجيا

- نوع 110 غسل خام الذهب في جنوب أفريقيا

- آلات مناجم الذهب في التقوى

- ريكسون مخروط محطم

- طريقة التحكم في الغبار محطم

- الليغنيت التعدين في أستراليا

- الألمانية اللحوم المجمدة محطم

- كسارة الحجر المحمول للبيع في غابون

- Bridge Port Series Milling Pakistan

- Portable Small Rock Crusher For Gold Recovery

- Cone Crusher Seekpart

- Productivity Cone Mining Crusher From Palma

- Buy Low Price Cone Jaw Crusher Small Stone Impact Crusher Machine

- Ultra Slim Grinder 2 Litre Price In Sao Tome And Principe

- Free Online Project Report For Dal Mill In Gujarat

- Beneficio Cement Coal Crushers For Sale Hong Kong

- Quicklime Price From Carmeuse Ghana

- Hss Ball Nose End Mills

- Gold Mines Email Contact Directory

- Grinding Machine A5

- Spare Part For F Jaw Crusher

- Dosa Plate Price In Australia

- Gold Mining Hard Rock Plant Equipment