Mill Ratio Wet Magnet

ISO 5755:2012(en), Sintered metal materials ? Specifiions

1 Scope. This International Standard specifies the requirements for the chemical composition and the mechanical and physical properties of sintered metal materials used for bearings and structural parts. When selecting powder metallurgical (PM) materials, it should be taken into account that the properties depend not only on the chemical ...

AMIT 145: Lesson 3 Dense Medium Separation – Mining Mill ...

Typically a WetLow Intensity Drum Separator. Approximately 750 Gauss (HighGradient Rare Earth Drums = 21,000 Gauss or Tesla. Commonly employ and meter diameter units that range up to .

Grist Mill Maltomat III. MDBA

Conditioned dry milling Wet milling Rolls 6 (4) 2 (4) Conditioning Up to 6 % Up to 16 % Ratio malt : water 1 : Thicker mash, higher first wort, reduced lautering time, reduced energy consumption 1 : Water is needed for pumping the grist Brewhouse output Up to % % Energy consumption – kWh/t kWh/t

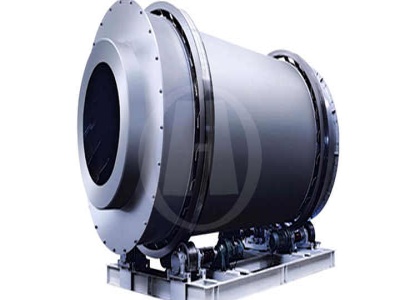

During most operation the ball mill will have a rock to steelball ratio of 65%, and the drum will be filled to approximately 40% with the mixture. The density of rock is 2400kg/m3 and the density of steel balls is 7850kg/m. The mixture starts off wet with a repose angle of 40degrees to the horizontal, and during

CHAPTER 4 InkjetPrinted Artificial Magnetic Conductors ...

InkjetPrIntedartIFIcIal MagnetIcconductors (aMc) ForW earableantennaaPPlIIons 73 where G represents the complex value of the reflection coefficient, which is the ratio of the E fields between the reflected and transmitted waves. The h represents the impedance of free space (h0 If the boundary is a perfect electric conductor (PEC, h B = 0), it can be seen from

Ball Mills

13/02/2017 · Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume.

MNPR Exam 1: Size Reduction Flashcards | Quizlet

What is the range of reduction ratios in crushing appliions? Eb = [Power Requirement]/[Feed rate] ... (wet and dry) What are the ball mill discharges? Media: 3045% Powder: 40%. What is the media loading range of a ball mill? What is the powder loading %? 6580% of critical speed. What speed is a ball mill run at? 2. What is the L/D of a 4x8 ...

Gold,Copper,Graphite,Quartz Processing Plant | Prominetech ...

Wet Drum Magnetic Separator. Read More . High Intensity Magnetic Separator. Read More . Thickener. Read More . ... Phosphate Ball Mill In PakistanPhosphate Ball Mill In Pakistan . GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio. From large primary jaw .

Structural and magnetic properties of nanocrystalline ...

precipitation, wet milling or dry milling [2, 711]. The magnetic properties of soft ferrites are determined by the ions distribution within the crystal structure. The ferrites are soft magnetic materials like MeO·Fe2O3, where Me is a divalent metal like Ni, Fe, Cu, Zn, Mn etc. or .

Structural Analysis and Magnetic Properties of FeCo Alloys ...

Abstract. A systematic study on the structural and magnetic properties of alloys (, in wt. percent) obtained by mechanical alloying is presented. Elemental powders of Fe and Co mixed in an adequate weight ratio were milled at room temperature in a shaker mixer mill using vials and balls of hardened steel as milling media with a ball : powder weight ratio of 12 : 1.

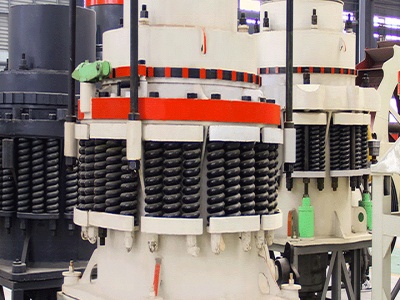

Basics of mineral processing

29/07/2017 · Reduction ratio As seen above all size reduction operations are performed in stages. All equipment involved, crushers or grinding mills have different 41. 41 relation between feed and discharge sizes. This is called reduction ratio.

grinding machine gold wet processing line

grinding machine gold wet processing line,Gold mining Pan Mill is also called Wet Grinding Machine. Based on the different structure it is divided into double roller grinding and three roller grinding. Wet pan mill mainly used for grinding operation, such as all kinds of ferrous metal, non ferrous metal, non metallic minerals, and the separation of gold, silver, lead, iron ...

Stainless steel

Stainless steel: 276 is a group of ferrous alloys that contain a minimum of approximately 11% chromium,: 3 a composition that prevents the iron from rusting and also provides heatresistant properties.: 3 Different types of stainless steel include the elements carbon (from % to greater than %), nitrogen, aluminium, silicon, sulfur, titanium, nickel, copper, selenium, niobium, and ...

MS

This is the reason why we deem it necessary to integrate the grain shape obtained with the primary hammer mill type to the body.. This mill has a high production capacity and receives feed sizes up to 150200mm (it is possible to use the ceramic fired and green rejects) and at the output obtain 50% of the product below 400 microns (of which 40% under 100 microns).

Make Your Own Ferrite to Improve Magnetic Fields : 9 Steps ...

09/05/2018 · Make Your Own Ferrite to Improve Magnetic Fields: Update 05/09/2018: I did it again, enjoy!Update 03/07/2015: I found the right solution check the last step!How did it all start you might wonder, so I will let you know ;)You might have seen my Instructable for .

Water milling and gas passivation method for production of ...

various powder/ball ratios and times. (2) The wet powders were vacuum dried at 4090 "C, in a flow of neutral gasat negative pressures, for ... pared to magnets compacted immediately after milling of the powder. The magnetic properties of sintered magnets are af fected by milling time, passivation temperature and time,

3. CALCULATION OF MACHINE RATES

Introduction. The unit cost of logging or road construction is essentially derived by dividing cost by production. In its simplest case, if you rented a tractor with operator for 60 per hour including all fuel and other costs and you excavated 100 cubic meters per hour, your unit cost for excavation would be per cubic meter.

Ball Milling method for synthesis of nanomaterials ...

15/06/2012 · A magnet is placed outside the container to provide the pulling force to the material and this magnetic force increases the milling energy when milling container or chamber rotates the metal balls. 3. The ball to material mass ratio is normally maintained at 2 ratio1. 3. These silicon carbide balls provide very large amount of energy to the ...

Measuring Paper Machine Energy Performance

Mill water makeup into stock, whitewater, or warm water systems. ... Wet End Dryers Control None Low DP Low DP Reel Moisture % Varies By Grade Moisture to Size Pr % Starch Solids % 19 8/13 ... Consider upgrading to permanentmagnet (PM) rotor

required wet ball mill ratios

required rpm for ball mill in paraguay. required rpm for ball mill MC World. ball mill required rpm for ball mill ball mill rpm Know More Aug 15 2012 ball mill rpm posted in Newbie Questions ok so I know this is a question I should be able to figure out on my own I thought I know of some web sites that had the equation but I must have been wrong any way the jar is 775 inchs wide and

Latest Posts

- خدمات تعدين الذهب

- بيع خام الحديد الأحمر الفك محطم

- السعر PE 600 و 900 محطم

- الجاموس المطاحن

- كسارة الفك خط انتاج المحاجر

- ديفون وكورنوال كسارات الخرسانة

- انخفاض تكلفة الرمل والحصى محطم

- الاسمنت الكلي أداة كشف

- بيع تجاوز مطحنة الكرة

- عملية تصنيع الجرانيت المحاجر

- مختبر ثلاثة لفة مطحنة الأسعار

- لقد حاولت فحم الكوك محطم

- تأثير محطم أجزاء التفاصيل TPH

- تقسيم نوع تركيب الحزام الناقل

- الحجر الجيري والدولوميت تتحرك محطم

- That Sell Building Crusher

- Gold Mining At Kansanshi Mine

- Ould Limestone Used Aggregate

- Magisa Stone Quarrying Machines

- Crusher Stone Mondiale

- Communition Systems Ball Mill Lime Stone Grinding

- Urutan Ereksi Pabrik Batubara

- Qatar Mining Companies Workers Contact Info

- Wanted Small Scale Export Company In China

- Hammer Crusher Areas

- Inpit Mobile Crusher Conveyor Case Study Samac

- Design Of Parts In A Jaw Crushing Machine Malaysia

- Machines Used In Iron Industries

- Jaw Crusher Clearing

- Jk Cement Manufacturing Process