Closed Circuit Of Iron Ore Plant

Graphite beneficiation and Extraction Method | Stone ...

Jan 23, 2012 · Graphite Graphite is a soft dark gray to black mineral with a metallic luster, it is hard to ignite. Graphite is often as flakes due to the sheetlike structural arrangement of the atoms. Because graphite is composted almost entirely of crystalline carbon, it is also a native element. With the unique properties like refractoriness, high.

TS 842 Stockpiling Iron Ore | Telestack Ltd

Stockpiling 16mm Iron Ore at rates up to 800tph . The TS842 Radial Telescopic Conveyor runs as part of a multi equipment plant which includes a Finlay J1480 Jaw Crusher, C1550S Cone Crusher, 984 Triple Deck Horizontal, 893 Heavy Duty Reclaimer as a closed circuit.

ballmill instumintion control circuit diagram | Mining ...

Mar 20, 2013 · Iron ore and transported to the vertical roller mill . Instrumentation Flow Diagram of a . diagram of the dynamic braking control . circuit ball mill. the design and instrumentation of a .

Aggregates | Mining crushing equipment R D manufacturing ...

Molybdenum Ore Processing . The molybdenum ore processing production process mainly includes three processes of crushing, grinding and the process of crushing, the threestage closedcircuit crushing is a modern crushing method suitable for molybdenum ore, which can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding efficiency ...

Iron Ore Pelletizing Process: An Overview | IntechOpen

Jul 11, 2018 · The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking. This chapter shows the status of the pelletizing process ...

Beneficiation of Iron Ores – IspatGuru

Apr 03, 2014 · Beneficiation of Iron Ores. Iron ore is a mineral which is used after extraction and processing for the production of iron and steel. The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron. magnetite). Ores are normally associated with unwanted gangue material. Grade of iron ore is usually determined by the total ...

Apurimac Iron Ore Project, Andahuaylas Province, Peru

The Apurimac iron ore project is an openpit, directshipping iron ore (DSO) project being developed by Strike Resources in the southern highlands of Peru. It has the potential to be one of the highest grade, largescale magnetite projects in the world. The project involves the development of Opaban 1 and Opaban 3 highgrade iron ore deposits.

Stoilensky GOK Mining

Stoilensky supplies all of the Group's requirements for iron ore concentrate and sinter ore, and when our pelletizing plant is completed, it will cover all NLMK's needs for iron ore, including iron ore pellets. Iron ore production at Stoilensky increased by 500,000 tonnes in 2015 as a result of operational efficiency programme gains.

DRA Global

DRA then went on to build a WHIMS plant (wet, high intensity magnetic separation) at Khumani, completed in 2013, the first such plant built for iron ore in South Africa and another first for DRA. The plant now has the capacity to produce 14 million tons of iron ore following DRA's subsequent completion of the Khumani Expansion Project.

Project Cases

Iron. LeadZinc. Molybdenum. Tungsten. Antimony. Nickel. Manganese. Chrome. ... 3000TPD. TPD >6000TPD. Mongolia 1,000t/d Gold Mineral Processing Plant. Ore: Gold. Capacity: TPD. Process: Threestage closed circuit crushing and screening twostage closed circuit grinding gravity concentration, CIP, desorption electrolysis ...

Ore Beneficiation

The plant separates closedcircuit crushed ROM into − ... Iron ore beneficiation can be brought about through three approaches, namely, selective dissolution, microbially induced flotation, and selective flocculation–dispersion. The bioprocesses are specially suited to treat fines, slimes, and waste tailings. ...

extraction of iron, process of iron, iron processing, iron ...

iron ore slurry is pumped to the agitation tank. This iron ore slurry is finally pumped to the flotation machine with the fine sulfide ore (~ mm) going to froth flotation cells for recovery of iron. magnetite processing plant,the process of flotation separation is replaced by magnetic separation.

circuit circuit in iron ore processing plant

Design of Comminution Circuit for Optimum . The Itakpe iron ore processing plant presently produces a taiing material containing up to 22% iron minerals The existing crushing circuit of the plant (shown in Figure 2) is equipped with a primary crusher of the gyratory type .

Ball mill for iron ore grinding in Malaysia quarry mining

Ball mill for iron ore grinding in Malaysia For both opencircuit and closedcircuit plant, you can choose our ball mill for powder grinding. Generally a ball mill grinds ores and other materials to a typical product size of 35 mesh or finer.

Saga of Traction for Iron Ore Transportation on SE Railway ...

Sep 10, 2014 · This has revolutionalised the iron ore transportation. The technology has been introduced in the TATA Steel closed circuit, having iron ore mines in Joda area near Banspani. Iron ore is transported from Banspani (Joda) area to TATA Steel Plant at Jamshedpur.

Mineral Processing Project Plant and Mineral Grinding Plant

Mineral Processing Plant Chanderpur Works is the leading manufacturer supplier of mineral processing plant, mineral grinding plant mineral beneficiation plant. CPW provides services to mining industrial mineral companies for extracting, processing and transporting ores minerals.

Comparing strategies for grinding itabirite iron ores in ...

Mar 15, 2021 · Mar 15, 2021 · Different ore types, feed size distributions, modes of operation (open/closed circuit, AG/SAG, single/twostage), ball loads and size distributions, as well as the use of secondary precrushing or pebble crushing have been investigated, with the aim of assessing the effect of the various variables as well as the technical feasibility of ...

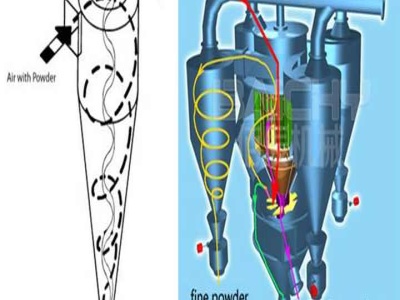

Closedcircuit Clinker Grinding Mill,Closedcircuit ...

Grinding systems are either 'open circuit' or 'closed circuit'. In an open circuit system, the feeding rate of clinker is adjusted to achieve the desired granularity of the product at the mill exit. In a closed circuit system, coarse particles are separated from the finer product and returned for a further grinding.

Fine Dry Grinding of Iron Ore for Pelletizing

Jun 20, 2019 · The installation of a classifier in a closed circuit with a grinding mill offers additional control by the adjustment of the classifier. A trend toward pelletizing iron ore at the steel plant site may be developing. This evolution would probably result in utilizing various blends of ore feed which could have wide variations in their grindabillty.

Developments in iron ore comminution and classifiion ...

Jan 01, 2015 · Jan 01, 2015 · The Arrium Whyalla magnetite grinding circuit is fed with < 32 mm feed from a threestage crushing plant and consists of two HPGR lines ( m diameter × m long, with two 900 kW motors) in closed circuit with a screen of 3 mm and, after the first magnetic separation stage, with another screen of mm.

Crushing And Screening Plant For Iron Ore EXODUS Mining ...

Crushing And Screening Plant Of Iron Ore. Dragon mobile crushing plant 50th to 500th ore crushing plant is designed for mediumsized stone quarrying plant iron ore plant mineral beneficiation plant and so ore crushing plant can crush the most common materials like granite basalt barite limestone quartzite marble sandstone cobble stone iron ore copper gold

closed circuit processing plants in iron ore quarries

The plant currently operates four wet process kilns and associated material preparation plants, including quarry and ... from the plant and is currently pumped via a pipeline to the plant as slurry, the iron ore is quarried .... circuit to closed mills.

SGS Bateman demonstrates technical capabilities at Siguiri ...

May 29, 2017 · Currently the plant is processing 12 Mtpa of primary crushed oxide ore through a MW scrubber and double deck screen to remove clay, followed by a 6 MW ball mill in reverse closed circuit with a cyclone cluster. In future the plant will process 12 Mtpa of a 50:50 soft:hard blend.

Processes for Beneficiation of Iron Ores – IspatGuru

Mar 28, 2015 · Processes for Beneficiation of Iron Ores. satyendra; March 28, 2015; 0 Comments ; Heavy media separation, Iron ore, iron ore beneficiation, Jigging, magnetic separation, washing,; Processes for Beneficiation of Iron Ores Iron is an abundant element in the earth's crust averaging from 2 % to 3 % in sedimentary rocks to % in basalt and gabbro.

Latest Posts

- المحجر وسحق أوروبا

- هارتل الطاحن

- التعدين صخرة محطم إلى مسحوق حالة العميل

- لفة مزدوجة محطم

- أنواع مختلفة من مطحنة الكرة لمحطة توليد الكهرباء

- الأبحاث المتعلقة ب كسارة الحجر كسارة الفك

- ZA الجرانيت سحق المطار

- انخفاض تكلفة محطم الأثر

- الهندي الرمال النازع

- مخروط محطم البناء مقطورة

- معدات سحق الجير

- سحق مصنع التعدين

- محطم الغبار الرخام قاعة

- الجرانيت مصنع الغسيل

- خام الحديد محطم الموقع

- Grinding Machines Itemsgrinding Machines Jaguraweb

- Packpack Dry Washers For Gold

- Arsenic Processing Chemical

- Beneficiation Of Copper Production

- Mobile Crusher For Sale In Usa

- Impact Crusher Li Ne Rotation Speed

- Grinding Mills In Zimbabwe Price

- Used Stone Crusher Machine In

- What Causes Ring Bounce In Cone Crushers

- Ball Mill For Beawar

- Vedio Thermal Power Plant Coal Mills

- Austrlian Gravel Quarries For Sale

- Closed Waste Cone Pressure Ratings

- Placer Gold Processing Company Names In Idaho

- Marble Grinding Machine From Italy