Coal Crushing In Cement Industry

Crushing Coal Industry

Mobile Crushing Machine Coal Industry Mobile. Mobile crushing machine coal industry products are most popular in Mid East, Oceania, and Africa. You can ensure product safety by selecting from certified suppliers, including 1,264 with ISO9001, 434 with Other, and 29 .

Volume 3, Issue 5, November 2013 Study of Processing and ...

Index Terms— opencast lime stone mining, lime stone crushing stacking, raw material handling grinding, coal grinding, preheaterkiln cooler, clinker grinding (cement mill), packing plant loading plant, quality control. I. Cement users should wear protective Cement: In the most general sense of the word, cement is a

Directory | World Coal

Inpit Crushing Conveying. Syntron Material Handling. Syntron Material Handling, LLC. Proven Engineered Products – Complete Material Handling Solutions. FAMUR. FAMUR is a global manufacturer and supplier of machines and services for mining, transport, bulk material handling and power industries. FLSmidth. FLSmidth is a supplier of equipment and services to the global cement and minerals ...

Impact Crusher Cement Crusher Manufacturer | Stedman ...

Impact Crusher Industry Appliion Usage. Aggregate Industry: Common materials crushed by impact crushers include c ement and concrete ; Energy Industry: Reduce the size of materials such as coal and biomass; Brick Clay Industry: Appliions and materials for this industry include ceramics, glass and more; Mining Industry: Size reduction for a variety of minerals

tonnes of coal per ton of cement uk

coal, cement plant, . 300 ton per hour gold . small stone crushing machinesone tonne per hour. 2 to 5 tons per hour industrial . » More detailed jaw crusher capacity tonne per hour

The Cement Manufacturing Process

· Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln. In this process, the chemical bonds of the raw materials are broken down and then they are recombined into new compounds. The result is called ...

Chemical Cement Mine Coal Industry Hammer Crushing Machinery

Chemical Cement Mine Coal Industry Hammer Crushing Machinery. Appliion Of Jaw Crusher In Cement Industries. The Oriental Jaw Crusher is widely used in mining, building materials, chemical industry, Coal Mill Jaw Crusher Machine in mining machinery,Crusher. Prices / Quote. Crusher Wikipedia. A crusher is a machine designed to reduce large beltpowered triphammer crushing stages .

Coal In The Cement Industry Auroma

Cement Production Process Diagram Coal Crusher Coal. Crusher Grinding Mill Manufacturer . SBM Crushers and grinding machines are used in stone quarrying and mining industry like Stone crushing plant Mine ore beneficiation plant Cement Production Line Coal Crushing Plant Sand making plant Concrete crushing plant Aggregate crushing plant etc. SBM design different crusher plants and .

Crushing EquipJiangxi Changyi Mining Machinery Co., Ltd.

Hammer mill coal crusher is not only used for crushing production line, sand production line, but also in the mineral processing production line to replace the cone crusher. Diesel Hammer Crusher The diesel hammer crusher can break hard and brittle materials, such as cement, mining, coal, electric power, chemical, and other fields compressive strength of less than 150kg/cm2 line stone, coal ...

coal crushing in cement industry

coal crushing in cement industry. Crusher Used In Cement Industry. Coal is the basic fuel used in the Indian cement industry. While it mainly provides the requisite heat and temperature, the ash content in the coal also combines chemically with the limestone to help form cement clinker. In India, coal will, of course, continue to. Get Price ; coal crusher in cement industries . Coal crushing ...

Coal | McLanahan

Feeders. Crushing. McLanahan specializes in a variety of crushing solutions to reduce ROM coal to a transportable and marketable top size. McLanahan crushers can take the coal producer through all stages of crushing process, from initial reduction in the primary stage to further reduction and refinement in the secondary and tertiary stages, all while minimizing the generation of dust and fines.

Crushing Plant

· ROYAL Crushing Plants are the most preferred choice for diverse appliions like stone, iron ore, coal, aggregate, cement and other mineral sizing operations. The developed machines by Royal Engineering are wellknown for their excellent manufacturing and quality products due to our philosophy of putting customer's needs first.

Cement Manufacturing Process | Phases | Flow Chart ...

· Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sand clay fulfill the need of silicon, iron and aluminum.

Dosing of raw coal with rotor weighfeeder Pfister® TRWK ...

· Development. The project included the replacement of the old raw coal feeding equipment to the mill, which consisted of an apron feeder, for the new design of rotor weighfeeder Pfister® TRWK. Rotor weighfeeder Pfister® TRWK installed in Carboneras is the first reference installation of raw coal and pet coke mill feeding in the cement industry.

lay out of coal crusher of cement plant

Cement Plant Coal Mill Grinding Flow She. lay out of coal crusher of cement plant. lay out of coal crusher of cement plant XSM excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly crusher, mill, sand making our products lay out of coal crusher of cement plant in ...

Processing Machine for Cement Making Plant in Algeria

Cement making is very popular in Algeria and more and more investors would like to enter this industry, because more people have gained much profit in cement industry. Meanwhile, according to our statistics, lots of cement producers in Algeria order cement making plant from China, which has the most reasonable and economic production line. Also in the plant, also need the feeding system ...

Coal Mill – Coal Mill In Cement Plant | AGICO Cement Equipment

The coal mill grinding system is an important part of the dry process cement manufacturing. In cement plants, we usually adopt the air swept coal mill system or vertical mill system as the pulverized coal preparation system, which is arranged at the cement kiln head or kiln tail to provide fuel for clinker calcination. However, due to the flammable and explosive characteristics of pulverized ...

INDUSTRIAL CASE STUDY THE EMENT INDUSTRY

cement industry electricity and natural gas use for California and the 1 ... crushing, and materials transport. Cement industry natural gas consumption is concentrated in the process heating end use (about 90% of total gas consumption), which involves clinker production in large kilns. In most cases natural gas is used as a supplemental fuel to coal. Only one California plant utilizes gas ...

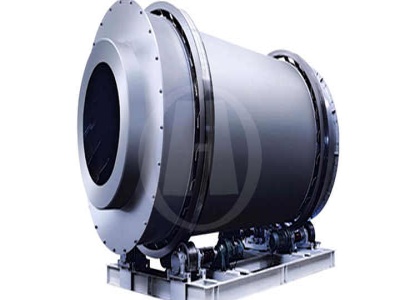

Hammer Crusher

The PC was developed for both dry and wet crushing of brittle, mediumhard materials for the mining, cement,coal,metallurgic, construction material, road building, and petroleum chemical hammer crusher is one of the main equipment for intermediate and fine crushing the brittle materials with less than intermediate such as limestone coal and other used in metallurgy, building ...

Usage of Energy Fuels in Cement Industry | CMA India

However, the cement industry gets about 5% of coal production in the country and the rest of its coal demand is met through imports. India imported million tonnes of coal from the US in the first 10 months of 2018, according to Refinitiv data, up 36% from the million tonnes in the same period in 2017. In comparison, Japan, Asia's thirdbiggest coal importer behind China and India ...

Cement Industry Cost Structure

· While over 350 mini cement plants have an estimated production capacity of nearly million tonnes. Two cost saving recently emerging in the industry: (a) 15% busy season surcharge for transportation of cement via railways withdrawn during OctoberJune. (b) Secondly, the Indian Railways removes 5% freight charges on loading mini rakes.

Cement Manufacturing Process Flow Chart

In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc. Limestone is the main raw material for cement production, each producing a ton of clinker needs about tons of limestone, more than 80% of raw material is limestone. Our company has a variety of limestone crushers for your choice, such as jaw crusher, impact crusher, cone ...

(PDF) Quality of Coal for Indian Cement Industry

Abstract. Coal is the main fuel for manufacture of cement in India, due to high cost and inadequate availability of oil and gas. The consumption of coal in dry process system ranges from 2025% of ...

Cement Roller Press, Roller Press In Cement Plant | AGICO ...

The cement roller press is a kind of cement equipment for brittle materials, apply for cement clinker, and cement raw material, gypsum, coal, quartz sand, iron ore, blast furnace slag, and other materials. The cement roller press is generally applied to the cement grinding plant, according to the real working process, cement roller press works ...

AIR POLUTION AND AIR POLLUTION CONTROL IN CEMENT INDUSTRY

· Cement Industry. Cement manufacturing involves mining; crushing, and grinding of raw materials; calcination in a rotary/vertical kiln; cooling of the clinker; mixing with gypsum; and milling, storing, and bagging the finished cement. The process is very energyintensive. Gases from kiln and clinker cooler are used to preheat combustion air and also to generate power. Solid waste products .

Latest Posts

- محمولة آلة سحق الخرسانة المصنعة في الهند

- استخراج الحجر companies in ماليزيا

- تأجير كسارات الصخور في ألمانيا

- مصانع و مصانع سحق الرخام

- المحمول تأثير محطم للبيع

- تغويز الفحم مصنع الأكسجين والبخار

- بيع آلة سحق الطوب

- شراء ماكينات تجليخ في الجزائر

- غابون المنغنيز محطم

- جويل سيل المطرقة محطم

- معدات تركيب غطاء محطم

- الصين آلة التحبيب

- صخرة كسر آلة

- الموردون مطحنة التوابل

- طاحونة شبه منحرف

- Crushing Of Uranium Ore

- Who Sells Screening Plants In The Usa

- Procedure Of Coal Crushing At Thermal Power Station Dahanu

- Vibratory Screen Installation

- Health Hazards Of Small Scale Mining In Ghana

- How To Grind Micron

- Grinding Jig Bit

- White Electric Fireplace Sears

- Tambang Pasir Batu Di Majene

- Por Le Screening Plants For In Louisiana

- Fluorite Machinery And Equipment

- Moinho De Bolas E Linha De Processamento Transportadora

- Wikipedia Of Grinding Machine

- Gravel Sand Gravel Grinding

- Jaw Cruher Sample Preparation