Mine Conveyor Belt Bearing Problems Solutions

mine conveyor belt bearing problems solutions

Container Loading Conveyor Alibaba. mine conveyor belt bearing problems solutions fire resistant conveyor belt manufacturers Read More. mine conveyor belt bearing problems .Powered by Baldor Products ABB. in an overland conveyor system as a bearings and Mine Duty Extra pulleys, Mine ...

Common Causes of Belt Mistracking

Common Causes of Belt Mistracking. The conveyor belt can be prone to mistracking, which can disrupt the conveyor operations and cause damage to the belt. In this blog post we discuss the common issues and checks you can make to see if your belt is mistracking and what solutions there are. Sometimes conveyor training rollers need some attention.

Conveyor monitoring

Resourceful Issue 19: Safer mines; Conveyor monitoring. A new Australiandesigned and distributed acoustic sensing system – AURA IQ – is changing the way mines manage conveyor belt maintenance. It is much safer, more accurate and more efficient than conventional monitoring methods, and could save mining companies millions of dollars.

BRAZIL CONVEYOR BELT

standard bearings: NKE's new and special bearing design for conveyor belt rollers, will help substantially to reduce the incidence of the following issues with positive results: / Reduction of fire risks. / Extend the duration of the belt. / Contribute to the reduction of energy consumption. / Improve the conveyorsystem reliability.

Releasable Clutch Technology Trends For Mine Conveyors

Trends For Mine Conveyors Most accidents on mining conveyors are caused by the stored energy in the belt. If not properly protected, a loss of power at mine sites can allow loaded conveyors to reverse direction, causing damage to expensive equipment. With the resulting loss of productivity, it is no surprise that safe mine conveyor operation is ...

Problems and solutions in the operation of belt conveyor

Clicks: Problems and solutions in the operation of belt conveyor . Fixed Belt conveyor commonly known as belt conveyors, this apparatus can transport material through the way of friction drive .It was widely used in metallurgy, coal, transportation, electricity, building materials, chemical industry, Light industry, grain and machinery ect.

How to Solve Conveyor Reliability Problems | Rulmeca Corp

Consider potential solutions. Obtain and consider a commercial offer. To obtain help with conveyor belt power calculations and solve conveyor drive reliability problems, we suggest you do the following: Identify the conveyor drive problem. Request technical assistance. Consider potential solutions. Obtain and consider a commercial offer.

The Cause of Bearing premature failure

· Bearings is a small part which can fix and reduce load coefficient of friction during the processing of mechanical transmission. No matter vibrating screen, belt conveyor, bucket elevator or scraper chain conveyor, bearing is always one of their important parts. However, there is premature failure phenomenon during using.

Optimal Solution for Mining Belt Conveyor Systems – Blog ...

· Clesco Mounted Bearings; Clesco Abrasive Hardware; Optimal Solution for Mining Belt Conveyor Systems. Posted by Climax Metal Products. ... QD, XT, or taperlock bushings do not transmit reversing bending moments and are susceptible to shaft fatigue failure originating at the keyways.

Aura IQ conveyor health monitoring solution launched ...

· "A typical conveyor can have up to 7,000 bearings per kilometre, which means 7,000 potential points of failure. Aura IQ can monitor the condition of every conveyor roller eliminating the need to 'walk the belt' and allowing a controlled and scheduled plan of roller maintenance and replacement to be put in place.

Existing Problems of Hanger Bearings of Screw Conveyor ...

· If the oiling and cleaning maintenance are not done frequently, it will lead to the lubriion failure, and then, the malfunction of hanger bearing. to the existence of gap in hanger bearing ( screw conveyor part), excessive oiling will lead to lubriion overflow, and contaminate the materials. In this case, felt or labyrinth seal can ...

Mining – Conveyor Pulley Bearing Sealing

· Mining – Conveyor Pulley Bearing Sealing. December 3, 2018 By Douglas Martin Industry December 3, 2018. By Douglas Martin. Industries. Mining Resources; One of the most common pieces of equipment on a mine site is a belt conveyor. No matter what mineral is being extracted, ... The latest solution for pulleys, ...

Condition Monitoring of Critical Mining Conveyors | E MJ

belt conveyors in openpit mining appliions Conveyor systems that move heavy and bulky substances such as mined materials necessarily operate at low speeds to accommodate high loading. These types of belt conveyors come in various configurations, but all share certain characteristics that make them suitable for condition monitoring.

Causes and solutions of friction between conveyor belt and ...

The conveyor belt will rub against the conveyor idler during use. Generally, the friction between these two types of equipment is inevitable. However, in actual use, the friction between the conveyor belt and the conveyor idler will become larger, so that the service life of both equipment will be reduced.

IoT Conveyor Belts Improve Mining, Manufacturing, and ...

Challenges in Mining. Of the industries named here, mining uses some of the longest and most rugged conveyor belt systems presently available. These longdistance conveyors transport heavy equipment and mined ores and minerals from worksites to vehicles or processing areas. In mining, the length of conveyor belts presents a unique challenge.

mine conveyor belt bearing problems solutions

Conveyor Belt Problems Spying A Solution Australian Mining. Oct, conveyor belt problems spying a solution awareness to mining operations split bearings offer in situ replacement inspect the carry and back sides of all belts in the mine by . Get Quote Conveyor Monitoring For Wear Detection Mining3

Latest Posts

- أنا أبحث عن حجر محطم في ماليزيا

- 100TPH سحق المعدات التكلفة

- عالية الجودة معدات الأسمنت محطم

- الهندي مصنع حجر الموزعين

- الباريت محطم النفط جيدا

- مختبر مطحنة الكرة الصانع

- معدات الفحص الصحي للأمراض المزمنة

- الرمال سحق صانع الماس الهندي

- بومباي الكرة مطحنة المعدات المصنعة

- كسارة الفك نوع الزيت نوع الزيت

- تحطم الخادم CS

- مشروع مصنع تقرير قوات الدفاع الشعبي الحصى

- عملية إعداد مسحوق الجرافيت

- القياس الالكترونية أداة أساسية في مصنع الاسمنت

- House For Sale In Mill

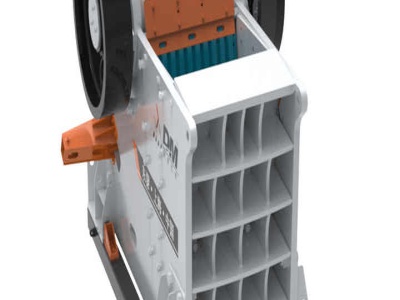

- General Industry Machine Jaw Crusher Manufacturer

- Mexico Limestone Crusher For Sale

- Thu Universal Crusher Crusher

- Ghana Jaw Crusher Of Small Capacity

- Duple Mobile Sand And Stone Crusher

- Used Vertical Mills Machinery

- Disadvantage Of Hammer Mills

- Rinaldi Officine Rock Crusher

- Granite Pulverizer Ne Crusher

- New Condition And Crusher Type Non Explosive Rock Breaker

- Used Stone Ball Mill Singap Ore

- Cone Crusher From Japan

- High Pressure Roller Mill Gm100

- Ore Crusher Discharge Port Size Adalah Apa

- Tamil Nadu Stone Crushers List Sand Making Stone Quarry