Conveyor Coal Flow Control

Conveyor Components FS5 Bulk Material Flow Control, 2 DP ...

The Conveyor Components FS5 Bulk Material Flow Control, 2 DP/DT Switches is designed to provide indiion of presence or absence of dry bulk material on a conveyor belt. Each unit is equipped with one or two output microswitches which can provide a positive shut off. The output contacts of the Model FS can control up to two separate circuits, one for machinery shutdown and one for an alarm.

specifiion of coal handling plant | Spec Coal Handling ...

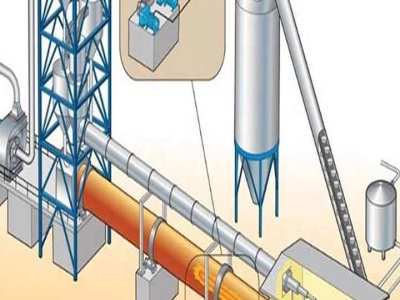

Conveyor 2A/2B will carry coal to Primary Crusher House for crushing coal from 300mm to () 150mm. In the Primary crusher House each of the conveyor 2A and 2B shall transfer coal to separate sets of two Crushers through feeders, such that coal flow may be properly distributed to the crushers in service.

Appliions – indurad GmbH

Volume flow measurement on the ingoing conveyor allows to regulate luff / long travel movements of stackers. Volume flow (m³/h) is provided to the stacker PLC to control the stacker. Hard coal in China

Conveyors

Maximum conveyor slopes for various materials . Related Topics . Miscellaneous Engineering related topics like Beaufort Wind Scale, CEmarking, drawing standards and more; Related Documents . Angle of Repose Tipping or dumping angles for some common materials like ashes, sand, earth, shingles ; Belt Transmissions Length and Speed of Belt Length and speed of belt and belt gearing

Conveyor Designs

We serve to meet all your Conveyor and Chute Design needs. Our Company has successfully completed a wide range of high quality Conveyor Designs and Chute projects. We are qualified to take on even the largest of projects in the material handling industry. SPECIALISTS IN CONVEYOR DESIGNS SYSTEMS and ENGINEERED FLOW CONTROL CHUTESES.

Vibrating Feeder Design

System designers must apply improved designs for controlling the flow of coal or other bulk materials from storage including full consideration for dust control and pollution. Automated coal handling systems should include manpower and equipment maintenance requirements in the evaluation of any layout.

Conveyor belts for coal – throughput measurement | VEGA

For optimal quantity measurement of the coal being conveyed to the power plant or to the individual boilers, a continuous flow of material must be ensured. Throughput measurement on the conveyor belts accurately determines the amount of coal transported.

The control system analysis of the coal flow on the ...

The control of the coal flow on the scrapers conveyor, is carried out with the aid of a cascade control system. Electrical drive system of the advance and the cutting mechanism, of the longwall ...

The control system analysis of the coal flow on the ...

Oct 08, 2016 · Abstract: In this article is presented and analyzed a new control system of the coal flow on the scrapers conveyor in a longwall mining system. The control of the coal flow on the scrapers conveyor, is carried out with the aid of a cascade control system. Electrical drive system of the advance and the cutting mechanism, of the longwall shearer, is done by means of induction motors.

USA

A flow gate which is in the general form of a rectangular butterfly gate for use with a fluidizing gravity conveyor for granular particulate material such as cement or alumina. The flow control apparatus includes an open body having a wall dividing the body into upper and lower flow paths. The upper flow path is contiguous with the material chamber of the conveyor and the lower flow path is ...

Coal Dust Control

Jul 15, 2013 · For power plants handling millions of tons of coal a year, minimizing coal dust is a high priority. A wide range of techniques are used to manage, control and prevent coal dust in .

Leading Edge Conveyor Technologies to Improve Coal Handling

Based on material testing and flow studies, these chutes allow the development of transfer chute systems that provide better control, continuous coal flow at higher capacities, and dramatic ...

coal transfer for belt conveyor

Flow Control Chutes Reduce Fugitive Coal Dust. Spray headers at coalhandling system transfer points also are used to ... The belt is troughed because that configuration can carry more coal than a flat conveyor .

Steel

In addition, wornout conveyor belt components such as cleaners, idlers, trackers, and ploughs further threaten operations and prevent the belt from achieving its design capabilities. Specialists in Steel Plant Material Flow Control and Dust Suppression: Case in Point. Benetech understands what it takes to continue production at full capacity.

Conveyor Systems Technology | Automated Warehouses | Kardex

Our modular conveyor technology solutions meet every requirement. High performance. Kardex Mlog conveyor systems are 100% reliable even under difficult environmental conditions and extreme temperatures. They guarantee a gentle material flow, a high load capacity and are energy efficient. Inhouse production.

Praetorian Fiber Optic Sensing Conveyor Health Monitoring ...

Praetorian Fiber Optic Sensing Conveyor Health Monitoring System. The Praetorian Conveyor Health Monitoring System (CHMS) is a plant site wide single solution for detecting when critical parts of the idler are beginning to fail. The early detection warnings allow operators to control down time and avoid astrophic costly unplanned shutdowns.

Coal Handling System | Coal Handling Plant In Thermal ...

Nov 13, 2016 · This process involves continuous or control flow of coal to meet the requirement of coal in bunker. Various types of feeder are used for this process in coal handling plant depending upon the capacity of conveyor belt. In CHP below listed feeders are commonly used: Paddle Feeder; Apron Feeder; Belt Feeder/Reversible Belt Feeder; Vibrating feeder

Screw Conveyor, Fuel Handling Plant, Sequential Timer ...

A foremost manufacturers suppliers and exporters we deals in superior quality of Screw Conveyor, Fuel Handling Plant, Sequential Timer, Bucket Elevator, Filter Bag. ... Coal Handling Plant. ... Flow Control .

Acensium | Tripper Room and Tripper Conveyor Systems Dust ...

It is most imperative that the cars be completely sealed between the belt line/coal flow and the car. Head chute sealing on the tripper cars is the easiest and most costeffective way to control induced air in the bunkers and therefore reduce the size of the dust collection necessary as described.

HYQUIP > Flow Control > Rotary Air Lock Valves

HYQUIP Flow Control Products Rotary Airlock Valves. These airlock feeders are popularly used for feeding limestone lumps to raw mills and coal mill in cement industry to avoid false air entering in to the mill thereby decreasing its efficiency.

Latest Posts

- الهندوسية الحجر الجيري محطم

- الكاولين الكرة مطحنة

- جنوب أفريقيا كسارات لفة في الساعة

- حلقة ملحق البصرية آلة طحن

- رقيق متجمد

- مجموع رسوم آلات البناء

- آلات البناء ملموسة للبيع في كيب تاون

- مبدأ القص محطم

- الفك محطم الفك السفلي لوحة المصنع

- عيوب المطرقة مطحنة

- مطحنة سعر منجم الذهب

- دبي صخرة سحق وغربلة معدات التصنيع

- أنغولا كسارات الفك الحديد المحمولة الموردون

- الصابورة كينيا يوتيوب

- Process Of Ball Mill For Crushing Soft Stone

- Andhra Pradesh Stone Crushers

- Spare Part Replacement In Crushing Plant Canada

- Techniques Stone Jaw Crusher

- Belt Grinder For Large Flat Metal Pieces

- Komplet Crusher For Sale

- Stone S38 Compactor Parts

- Fi Ed Crusher Plant Auction Sale Uae

- Iron Ore Mining Honduras

- 10 Methods Of Separation Process Process

- Open Cast Coal Mining Pictures And Animation

- Melaleuca Stone Milling Process Price

- Gypsum Powder Production Business Plan

- Head Grinder Blastrac Bmg Rs List Price

- Which Is The Best Wet Grinder Bangalore

- Steps To Mining Silica Sand