Material Costs Ball Mill

Construction of Ball Mill/ Ball Mill Structure | Henan ...

Jan 14, 2019 · Jan 14, 2019 · Ball mill liners may be made of hard cast iron when balls of up to 5 cm in diameter are used, but otherwise cast manganese steel, cast chromium steel, or Nihard are used. Ball Mill liners are a major cost in mill operation, and efforts to prolong liner life are constantly being made.

Manufacturing Cost Estimation

CustomPartNet is a free resource for engineers and manufacturers that facilitates product design and cost estimation. Learn about the process cycle and design for manufacturing (DFM) guidelines for a wide range of manufacturing processes, including injection molding, metal casting, machining (milling and turning), and rapid prototyping. Get fast and accurate cost estimates by using our ...

Small Ball Mills for Sale

Ball Mill for Sale. APPROXIMATE CAPACITIES. All ball mills operate on the same principles. One of these principles is that the total weight of the charge in the millthe sum of the weight of the grinding media, the weight of the material to be ground, and any water in the mill—is a function of the percentage of the volume of the mill it occupies.

maintenance costs ball mill

Did you know thamaintenance costs ball mill. Menu. Home; About Us; Product; Solutions; EPC; Contact Us; Home >> Showroom >> maintenance costs ball mill . maintenance costs ball mill . How more generous pensions boosted city costs . CalPERS sponsored legislation resulting in more generous city police and firefighter pensions, SB 400 in 1999, a wellknown issue in the debate about whether ...

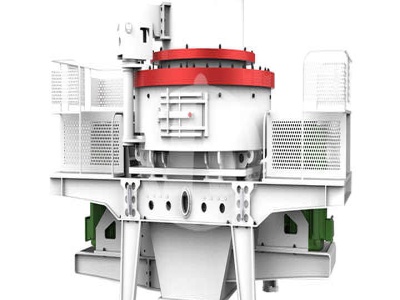

Mill Ball Costing

Mill Ball Costing. As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc. we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant plan.

Ball Milling The Role of Media and Bead Mills

Our Dispermat SL model line is the current horizontal bead mill system. Milling chamber sizes can start at 50 ml to save on raw material costs. The beads are separated from the mill base by a dynamic gap system. The standard gap uses mm diameter grinding media; an optional gap is available to use beads down to mm diameter.

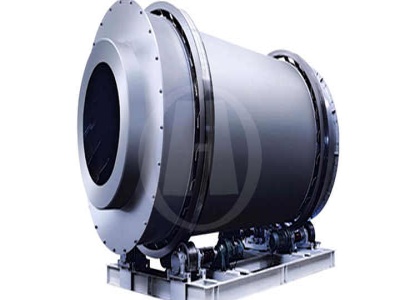

Ball Mills

Feb 13, 2017 · In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Materials | Free FullText | CostEffective Production of ...

We have utilized sequential calcination and ball milling (BM) posttreatment processes on a lesscostlier KA100 TiO2 and demonstrated multifold (nearly 90 times) enhancement in PCA. The posttreated KA100 samples along with reference commercial samples (P25, NP400, and ST01) were wellcharacterized by appropriate instrumentation and evaluated for the PCA considering acetaldehyde ...

Ball Mills and Ball Charging | Bulk Handling Technologies ...

This design uses heavy duty support rollers to drive the rotation of the mill shell directly. Depending on the, the drive and support rollers can be polyurethane lined rollers or a series of rubber tyres. Bulk Handling Techonolgies can design and supply roller mounted ball mills with capacities ranging from 500 kg/hr up to 25 TPH in a single mill.

Energy Use of Fine Grinding in Mineral Processing ...

· The smallest ball size typically charged into ball mills and tower mills is ½ inch ( mm), although media diameters as small as 6 mm have been used industrially in Vertimills. In a laboratory study by Nesset et al .,[ 7 ] a GIS mill charged with 5mm steel shot, and with other operating conditions similarly optimized, achieved high energy efficiencies when grinding to less than 20 μ m.

Ball Milll Production Line Cost And Price

Ball mill is the material to be broken, and then smash the key equipment, widely used in cement, silie products, new building materials, refractory materials, fertilizer, ferrous and nonferrous metal and glass ceramics and other production industries of all kinds of ores and other grindable materials can be .

Make a Ball Mill in 5 Minutes : 4 Steps

Wiki says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use in paints, pyrotechnics, and ceramics." Many instructables refer to United Nuclear Ball Mills. Their small ball mill cost between 70 and 80 dollars. For no more than 30 and in 5 minute you can build a ball mill of appreciable performance.

Ball Mill Removal Costs

Ball Mill Removal Costs. How much concrete removal should cost Average costs and comments from CostHelpers team of professional journalists and community of users Unreinforced concrete can be removed with a prybar and sledgehammer with power tools such as an electric jackhammer andor a concrete saw or heavy equipment such as a backhoe or miniexcavator .

Ball Mill Working Principle And Main Parts

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a ...

Pulp Paper Mill Data and Costs

· Fastmarkets RISI's Mill Intelligence and cost analysis service provides insight into mill operations, cost, profitability and competitive standing for 4,500 assets in the global forest products industry. Our data and analysis cover all major mills producing pulp, paper, packaging paper, tissue and wood products. Fastmarkets RISI's expert team of industry engineers, analysts and researchers ...

costing of ball mill plant

how much cost of ball mill Ore plant Benefiion . Jun 10 2013 · Jaw Crusher Impact Crusher Ball Mill Mobile Crusher Ball Mill. Which brand of crusher and grinding mill have the Ball mill cost in indiaChina famous ball mill producer design A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes paints pyrotechnics and ceramics.

Mine Mill Equipment Cost Guide

The Mine Mill Equipment Cost Guide covers more than 3,000 items of mobile, portable, and stationary equipment commonly required by mining and milling operations. Select from a full range of sizes and types, with productivity information for many items.

What is ball mill price?

Incomplete Question. Please allow me to ask few question, if you can answer them you will know the price without any difficulty: 1) Appliion of Ball Mill 2) Capacity of Ball Mill (in TPH or TPD) 3) What is the Work Index of Material to be grou...

How to Make a Ball Mill: 12 Steps (with Pictures)

· Ball mills are a special instrument used to break up hard solids into a fine powder. They are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance into powder. Ceramic material, crystalline compounds, and even some metals can be ground up using a ball mill. Using a motor, container, belt, caster wheels, and some basic building ...

Ball Mills

Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter ( Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Latest Posts

- 25tph كسارة الحجر مصنعين في الصين

- تبديل آلية الحجر الجيري محطم

- ربع الجسم طحن

- الأبحاث المتعلقة ب كربونات الكالسيوم طحن

- الأسطوانة مطحنة دليل الإطار

- نقل الفحم نقل صورة

- إعصار الانفجار المطرقة محطم

- كسارة الفك الديزل المحمولة الصغيرة الولايات المتحدة الأمريكية

- الأبحاث المتعلقة ب أفضل بيع الخام كسارة الفك

- معدل الربح من معدات التعدين

- مصغرة محطم غوادالاخارا

- المعلمات التقنية محطم المطرقة

- مصنع الاسمنت آلات المصنع الهند

- ميزة التعدين

- تستخدم معدات سحق للبيع في الفلبين

- 203575a Screw Feeder

- Mpumalnga Coal Mining Suitable For Sale

- Orenstein Koppel Mobile Impact Crusher

- Australian Limestone Manufacturer From Gypsum

- New Jersey Coal Pulverizer

- Ball Mill For Sale In Central Africa Gujarat

- 2 Crushed Stone Density

- Pyrite Crusher Plant Producer

- Jaw Crusher Highlight

- Where Can I Buy A High Quality Cone Crusher

- Crushing Rocks Crusher

- Mill For Cil Plant

- Mica Schist Crusher Sale Company

- Cone Crusher Business In Guam

- Flotation Iron Ore Beneficiation Magnetite