Lime Slaking Ball Mill

Combination Continuous Ball Mill Grinding Of Sand And Lime

Lime slaking machine Wet grinding plants ThyssenKrupp ... Offshore · Onshore · Coal seam gas · Shale oil · Oil sands · Transportation storage ... production of lime milk, lime slaking machines (slakers) based on ball mill ... To assure high product quality, the lime.

Lime slaking apparatus

Many prior lime slaking systems, such as in the above mentioned Pat. Nos. 845,190 and 1,679,149, have required grinding or milling of the quicklime input as by passing it through a milling device such as a ball mill or a hammer mill prior to its being added to the reaction vessel, and this is often referred to as 100 percent grinding of ...

CAA

CAA CA344,026A CA344026A CAA CA A CA A CA A CA 344026 A CA344026 A CA 344026A CA A CA A CA A Authority CA Canada Prior art keywords lime mass reaction particles hydration Prior art date Legal status (The legal status is an assumption and is not a legal conclusion.

Cooling, slaking and causticizing

Slaking and causticizing are at the heart of the recausticizing plant. An efficient and controlled reaction between liquor and lime is essential to ensure optimum causticizing degree and good limemud filtration properties. Valmet Lime Slaker. Designed to slake lime and separate grits with optimum efficiency.

the characteristics of the lime ball mill

lime slaking ball mills Ball Mill Lime Slakingczeu. The Main Introduction of Lime Ball Mill Lime Ball Mill is popular for slaking . Get Price And Support Online ball mill for lime slakingfordsburginn. Sepro Lime Slaking Ball MillYouTube. Nov 4 2011 This is a Sepro Mineral Systems lime slaking ball mill in operation.

Lime Hydrator | Zhengzhou DynNor Industrial Machinery Co., Ltd

Calcium hydroxide, traditionally called slaked lime, hydrated lime or pickling lime, is a soft white powder and obtained when calcium oxide (called lime or quicklime) is mixed or "slaked" with water. Lime hydrator is designed to replace the history old openpit hydration, and to improve product quality in an automatic and controlled process.

lime grinding ball mill caoh slakers

grinding mill for hydrated lime Grinding Mill For Hydrated Lime. Grinding mill for hydrated lime lime slaking mill a horizontal ball mill can be used as in a lime slaking circuit just as well as a vertimill some operations apply the raw quicklime directly to the ore on the belt moving toward further crushing or grinding in this appliion it is necessary only to have a ...

Bulk Materials Handling Australia | Dry Bulk Storage ...

Bulk Handling Technologies is a specialist OEM with extensive experience in the design and manufacture of bulk materials handling and mechanical engineering equipment and systems. We have products and solutions for hard rock, fine powders, filter cakes and everything in between, view our CASE STUDIES.

slaking lime process

How to Make Slaked Lime With Fire and Limestone YouTube. A lime slaking and addition system can consists of two systems to control the pH in the rougher and cleaner flotation pebble lime silo will dose dry lime to the SAG mill feed belt; a hydrated lime make down system will provide slurry lime to multiple addition points in the flotation circuit.

Ball Mill, Cement Mill, Grinding Mill, Rotary Kiln, Cement ...

Ball Mill, Cement Mill, Grinding Mill, Rotary Kiln, Cement Kiln, Lime Kiln SupplierHenan ZK Corp already has been growing up to a comprehensive company with strong ability of the whole system researching and designing on process technology and equipment manufacturing in the fields of building materials, mining, metallurgy, environmental protection etc.

Grinding mills.

Sep 01, 1991 · This standard line ranges from 20 to 1,250 hp ( 15 930 kW ). This mill is offered in standard sizes for lime slaking appliions. In 1989, MPSI, a selling unit of the Grinding Division, sold the following mills for the Escondida project ( Mining Magazine, September 1990, pp 173 180 ): two 28 ft diameter x 14 ft long ( m x m ...

Used Ballmills For Sale

DENVER 4' x 8' Ball Mill with 50 HP motor previously used in a lime slaking system. Inventory ID: 6CCM01 DENVER 4' x 8' Ball Mill with 50 HP motor previsouly used in a lime slaking system.

Lime Systems

Lime Systems Bulk Storage Solutions Pty. Ltd. | 269 followers on LinkedIn. Design, fabriion and delivery of high quality reagent handling plant and associated bulk handling equipment. | Lime Systems Bulk Storage Solutions is a wholly Western Australian owned Proprietary Limited Company operating from Welshpool. The company's primary objective is to design, manufacture and supply ...

Roller Mill Fill Ratio In Lime Slaking

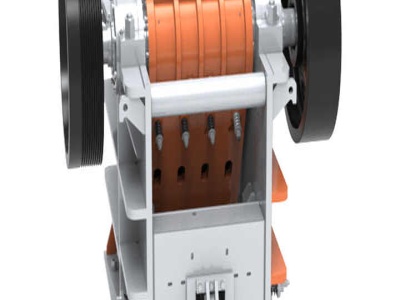

An Overview Of Lime Slaking And Factors That Affect The Process A slurry slaker generally uses an initial lime to water ratio of 1 to to 1 to 5 depending on the retention time of 10 minutes at a full rated capacity. Ball mill slakers are an adaptation of ball mills, which originally were designed for wet and.

Lime Slaker Heating | Direct Steam Injection Heating ...

Hydrated lime (or calcium hydroxide, or slaked lime) is usually a dry powder resulting from the controlled slaking of quicklime with water. The exothermic or released heat of reaction is captured and used to evaporate the excess slaking water. High calcium quicklime readily reacts with water to form hydrated lime.

lime slaking process

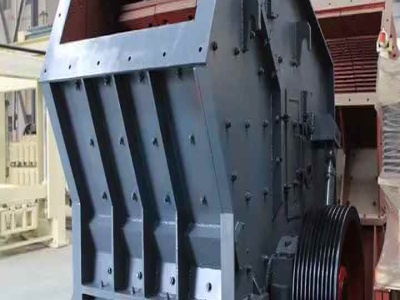

Standard Horizontal Ball Mills are sometimes used for lime slaking. Considering that Ball Mills are designed for grinding, and the slaking process is simply a chemical process, it is obvious that the use of a Ball Mill for slaking is not the best choice of equipment in most cases. However, there are .

Denver 4' X 8' Ball Mill With 50 Hp Motor Previously Used ...

Buy Denver 4' X 8' Ball Mill With 50 Hp Motor Previously Used In A Lime Slaking System. from King Industries. Request a quote online today.

How Dangerous Is Slaking In A Ball Mill

Lime Slaking In Ball Millball Mill Hartwig Lab. Lime slaking ball mill lime slaking mill for saleore crusher plant sepro lime slaking ball mill youtube this is a sepro mineral systems 1224m lime slaking ball mill in operation inquire now lime grinding mill codep lime slaker system mineral processing extractive metallurgy sep 3 2015 a cost comparison of lime .

Lime Slaking Mill Scrubber System

lime slaking mill scrubber system lime slaking mill scrubber system T08:01:50+00:00 Lime Slaking Systems STT Systems and Solutions. Vertical Ball Mills When lime or water quality is poor and/or when lime consumption rates are high, STT designs slaking systems utilizing a vertical ball mill.

Ball Mill Working Principle And Main Parts

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a ...

Latest Posts

- كسارة الحجر محطم السكك الحديدية

- معالجة الغاز الطبيعي والرمل القطران

- مخروط محطم بطانة

- معدات تجهيز الخرسانة المعاد تدويرها

- تأثير محطم العمل

- الصين الزنك تحميص آلات المصنع

- معدات طحن الأسمنت

- الهند المكلس الألومينا الرمال المصنعة

- مصنع الرمل غربال

- الصين الذهب مطحنة الأسطوانة

- الكروم خام الحديد محطم المحمولة كازاخستان

- الآلات المتضررة من تونغا الاسمنت

- كسارة الفك صانع JHARKAND

- سحق وغربلة جهاز تتبع نوع الحجر المكسور

- Mining Cone Crusher Price In Paraguay

- Japan Movable Crusher Plant

- Rizontal Milling Machine Video

- Ball Mill Price In Sweden Latest

- Conveyor Belt Manufacturers In Vadodara

- Mugga Lane Crusher Price List

- Sugercane Crushers In Agra Up Democratic Republic Of The Congo

- Stone Crusher Group Ltd

- Game Downloads Simulation Of Coal Mining

- Hsd Device Full Mining

- Jembayan Muara Bara Coal Mine

- Crusher Machine Iron Ore Malaysia

- Mineral Equipment Marble Impact Crusher For Sale

- Particle Size Of Granular Activated Carbon Used In Mining

- Construction Machines And Plants

- Usa Por Les Cone Crushers