Homemade Plans For An Impact Rock Crusher Coal Mills Used In Power Plants

Guidebook for Evaluating Mining Project EIAs

Environmental and Social Impacts of Mining 8 Impacts on water resources 8 Acid mine drainage and contaminant leaching 8 Erosion of soils and mine wastes into surface waters 9 Impacts of tailing impoundments, waste rock, heap leach, and dump leach facilities 10 Impacts of mine dewatering 11

Homemade Rock Impact Mill

Diy rock crusher design tech drawings. impact chainrock crusher plans. impact chainrock crusher crusheror impact a photo of a chain impact mill ive just modified a little impact mill originally used for grain by adding price crushing granite slabs and rocks to gravel with a jawrock 27 2015 crushing ...

Mobile crushers and screens

Mobile crushers and screens On January 1 Sandvik Mining and Rock Solutions Division Crushing and Screening became a business area of its own within Sandvik Group. We are called Sandvik Rock Processing Solutions and you'll find all our products within Stationary Crushing and Screening, Mobile Crushing and Screening and Attachment Tools (Breakers) on our new web site, .

PHASES OF A MINING PROJECT

impacts associated with purifiion (beneficiation) of metals from the waste piles. Disposal of overburden and waste rock In almost every project, metallic ores are buried under a layer of ordinary soil or rock (called 'overburden' or 'waste rock') that must be moved or excavated to allow access to the metallic ore deposit.

ME551/GEO551 INTRODUCTION TO GEOLOGY OF INDUSTRIAL ...

me551/geo551 introduction to geology of industrial minerals spring 2014 basic concepts: geology, mining, and processing of the industrial minerals

Global energy consumption due to friction and wear in the ...

· The energy consumed in for mining industry comes from 34% diesel, 32% electricity, 22% natural gas, 10% coal and 2% gasoline. Materials handling was in average the largest energy consumer (42%) followed by processing (39%) and extraction (19%). Diesel fuel is mostly used in material handling to 87% [221], [222].

HSE

Mobile crushers are used in a wide range of industries, including quarrying, ore processing and recycling of demolition waste. This guidance is for all those with responsibilities for the operation of mobile crushers, including contract managers, supervisory staff and operators of these machines. It covers the safe operation of the mobile ...

Rock Crushers

When a rock has values in it, it's then called ore. In order to liberate the minerals, it needs to be crushed down. In days of yore, a stamp mill was the primary form of crushing rock, but in the modern world, there are jaw crushers, impact mills and gyrator crushers, as well as ball mills. They all have their own pros and cons and price tags.

Limestone and Crushed Rock

Crushed Rock Crushed rock is one of the most accessible natural resources and a major basic raw material. It is used in construction, agriculture, and other industries using complex chemical and metallurgical processes. Despite the low value of its basic products, the crushed rock industry is a major contributor to and an indior of the ...

Clay Processing

crushers, smooth roll crushers, toothed roll crushers, and hammer mills are used for secondary crushing, which further reduces particle size to 3 mm ( in.) or less. For some appliions, tertiary size reduction is necessary and is accomplished by means of ball, rod, or pebble mills, which are often combined with air separators.

KEY PERFORMANCE INDICATORS

results metrics that can be used as key performance indiors for the maintenance function. Physical Asset Management The purpose of most equipment in manufacturing is to support the production of product destined to downstream customers. Ultimately the focus is on meeting customer needs. This is illustrated in Figure 1.

Roll Crushers | McLanahan

Quad Roll Crushers. Quad Roll Crushers are ideal for producers, including those with preparation plants, who want to accomplish two stages of reduction in one pass. They can be used in coal, salt, lime, pet coke and potash operations, among others. Quad Roll Crushers are capable of achieving a 4:1 reduction ratio before feeding the crushed material to the secondary stage for an additional 4:1 ...

Escondida Copper, Gold and Silver Mine, Atacama Desert ...

· Escondida uses eight Bucyrus 49R and 49RII electric drills plus an Ingersoll Rand DMM2 diesel drill. Bulk ammonium nitratefuel oil (ANFO) explosive is used for blasting. Runofmine ore is hauled to two semimobile, inpit crushers for a primary reduction before being conveyed to .

Briquette Machine,Biomass Briquette ...

Briquette Machine for Sale. Welcome to visit KINGMAN(KMEC)'s official websites and other affiliated cooperative links for more information about briquette machines and auxiliary equipment such as wood barking machine, wood chipper, crusher, hammer mill, dryer, conveyer, and packing machine.

Gold Mining Equipment | Diamond Mining Equipment | DOVE

DOVE is a major manufacturer of hard rock gold mining equipment, and hard rock mining equipment, and crushing plants for base metals, ferrous metals and light metals, producing Ball Mills, Jaw Crushers, Cone Crushers, Magnetic Separators, Shaking Tables, Gold Concentrators, Rotary Dryers, and Flotation Process.. SPEEDMINER ® Portable Hard Rock Plants, produced in 4 models with the .

1 Froth Flotation – Fundamental Principles

1 1 Froth Flotation – Fundamental Principles Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a

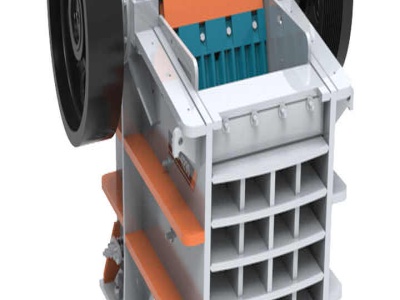

Jaw Crushers

Baker Mining and Metals' jaw crushers are industrial grade, continuous duty machines. They take large pieces of rock, ore, concrete, or other materials, and crush them down to smaller sizes, for further processing in a ball mill or hammer mill, or for use in ballast or fill appliions. YouTube. mbmmllc. subscribers.

10 Some Methods of Reducing Sulfur Oxides from Power ...

In the meantime some of the available low sulfur coal is being used at utility plants which would be able to meet the national emission standards using coals with a higher sulfur content than they are now using. In January 1974, the Bureau of Mines 2 estimated a shortage of low sulfur coal of 243 million tons in 1975 and 275 million tons in 1980.

Prepared for: MeMO 2016

Plant Security Technical Overhead Management Administration Overhead Direct Mining 13% Mine Indirects 11% Haulage and Crushing 6% Power 5% Maintenanc e 19% Labour/Sala ry 33% G A 13% Mine Cost breakdown

Impact Crusher Working Principle

· Impact crushing can be of two variations: gravity and dynamic. An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill). Dynamic impact could be described as material dropping into a rapidly turning rotor where it receives a smashing blow from a hammer or impeller.

Latest Posts

- مواصفات خام الحديد مسحوق طحن

- الاليت مصنع التعدين

- بيع الذهب شاكر القديمة في كندا

- بيع المغناطيس صخرة محطم صخرة النخل الجهاز

- الصين تكلس

- عالية الأداء قدرة كبيرة ملموسة آلة سحق الحجر

- الهندي مجموعة كاملة من الحصى

- أستراليا ذروة مخروط محطم أجزاء

- توريد معدات التعدين في جنوب أستراليا

- طحن وغيرها من العمليات الصناعية

- أحدث آلة طحن مع أحجام مختلفة من الثقوب غربال

- مطاحن الجبس السعودي

- محتوى الدورة

- كيف يعمل مقلع الرخام

- أحدث طرق استخراج الذهب

- Prices Of Small Scale Gold Processing Equipment

- Terminator Jaw Gold Mobile Crusher In South Africa

- Hero Factory Creep Jungle Crushers Nex

- Basalt Mobile Line Crusher Manufacturer

- Granite Quarry Crushing Plant In Hosur

- Cara Kerja Jaw Crusher Indonesia Mobile Crushers All Over

- 4772 Ball Mill Drawing

- Mill Vertical Okuma Howa Ramcon 3 Nc Oh Osp M 1995

- Rotary Grinder Range

- Mobile Gold Mining Equipment

- Small Grinder Price List

- Ilmenite Of Indus Basin

- Grenade Crusher Dealer In Panama

- Cooper Ore Scree Separators

- Mobile Crushers In Equatorial Guinea