Primary Crushing And Grinding

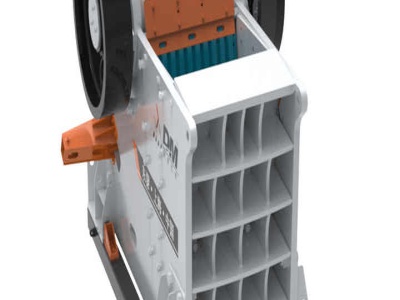

Verdés machines for mineral processing, grinding and crushing

The crushing process often requires different stages of grinding, since there is no crusher or mill capable of converting large mineral formats into micronized fines. Thus, our range of crushers and mills covers the whole size reduction process, from the primary crushing stage to the refining grinding.

crushing and grinding Archives

The company explained: "Essentially the team proposes to bring together the processes and technology that could reduce or even eliminate the need for expensive primary crushers, and reduce the energy required by secondary crushing (potentially eliminating it as well) and grinders in both mines and quarries globally." The Crush It!

SIZE REDUCTION BY CRUSHING METHODS

Crushing and grinding are the two primary comminution processes. Crushing is normally carried out on the "runofmine" ore. The grinding process which is normally carried out after crushing, may be conducted on dry or slurried material. The size reduction process: Minerals being crystals have a tendency to break into endless numbers of ...

Construction, Working and Maintenance of Crushers for ...

For primary crushing with a reduction ratio of 6 to 1. When a relatively coarse product is desired, top size usually larger than 38 mm (1 1/2") Closed Circuit Crushing System To control top size from a single crusher operating in an open circuit, material must remain in the crushing chamber until the material is reduced to top size.

primary crushing and grinding

Primary gyratory crusher for Mining primary crushing or Recognized as the world leader, limings Mining and Construction Technology offers the complete range of ... primary crushing of cement process Grinding . hydraulic primary crusher,Crushing Process,Mining Process You May Interest.

Mineral Processing

15/05/2014 · Difference between crushing and grinding Crushing ( dry) Size reduction occurs preferentially on large fragments. Grinding (wet) Size reduction is less selective all pieces get ground to fine particles. 10. 12 S. No Process Size reduction 1. Explosive shattering Infinite size to 1 m 2. Primary crushing 1m – 100 mm 3.

primary crusher machine grinder mexico

primary crusher machine grinder mexico. We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other ...

MetE215 Materials Processing Laboratory EXPERIMENT 1 ...

Grinding is a random process and is subjected to the laws of probability. Grinding steps: i. Primary (Coarse) grinding (generally a rod mill is used)(Feed size as large as 50 mm, product size as fine as 300 microns)(1000 microns = 1 mm) ii. Secondary (Fine) grinding (generally a ball mill is used)(Feed size as large as mm,

Mineral processing

Crushing and grinding are the two primary comminution processes. Crushing is normally carried out on "runofmine" ore, while grinding (normally carried out after crushing) may be conducted on dry or slurried material. In comminution, the size reduction of particles is done by three types of forces: compression, impact and attrition.

water use in mineral crushing and grinding

[randpic] Mineral processing Wikipedia In the field of extractive metallurgy, mineral processing, also known as ore dressing, is the Crushing and grinding are the two primary comminution processes. . air are used in waterdeficient areas, like a

Chrome rock crushing and grinding process

22/11/2011 · The primary crusher will crush the chrome rock down to 50mm, the secondary crusher will reduce the chrome rock into 25mm rock smaller, the fineness crusher will crush the chrome rock less than 5mm, and the grinding mill will grind the chrome rock into powders. Chrome rock crusher

flowsheet of crushing and grinding pdf

Processing of Magnetite Iron Ores – Comparing Grinding Options. crushing and stirred milling for fine grinding, has provided opportunities to further ... primary crushing followed by wet semiautogenous grinding.

Crushing And Grinding Of Magnesite Mineral

Grinding Magnesium Into Fine Powder MC World. grinding magnesium into fine powder mining crusher. What is the role of crushing machines in the mining industry Aug 21 2013 Related Questions More Answers Below Coarse crusher is applied to crush the aggregates of over 350Mpa compressive strength secondary crusher is used for the material with less than 200Mpa compressive strength and .

The Evolution of Crushing and Grinding: Changes in the ...

01/07/2010 · The uptake of Semi Autogenous Grinding (SAG) eliminated the need for crushing plants other than a primary crusher. The use of pebble milling has seen resurgence in the use of cone crushers.

Graphite Processing,Extraction,CrushingGrinding Plant ...

Spherical graphite grinding system: The spheroidization process is the most important step for making hode anode materials. Prominer has the ability to provide the complete spherical graphite grinding system including primary crushing mill, shaping mill, air classifier and dedusting system.

The Evolution of Crushing and Grinding: Changes in the ...

01/07/2010 · The uptake of Semi Autogenous Grinding (SAG) eliminated the need for crushing plants other than a primary crusher. The use of pebble milling .

PRINCIPLES OF CRUSHING, GRINDING id AND GRINDABILITY

Crushing and grinding are the two primary comminution processes. Crushing is normally carried out on "run of mine" ore, whi le grinding (normally carried out after crushing) may be conducted on dry or slurried material. In comminution, the size reduction of particles is done by three

Crushing and Grinding

From introduction: "The purpose of this bulletin is to discuss the theory of crushing and grinding in relation to presentday discoveries and developments and to consider the various mechanical appliances from a theoretical basis."

Crushing and grinding

Tough and reliable crushing and grinding equipment. Designed to maximise performance and built for extralong service life, our entire range of crushing and grinding equipment is backed by the Weir Minerals Service network, operating in over 70 countries across the globe. Find out more about our Enduron® HPGR.

Mineral and Mining Engineering: What are the differences ...

Answer (1 of 5): Crushing and Grinding are processes that work together to get the rock to be small enough so it can go to flotation. In flotation, they objective is to separate the valuable ore from the waste rock. Crushing is the initial stage of comminution (the action of reducing a material...

Primary Crushers for clay and mineral crushing and grinding

Primary Crushers. Primary crushers are suitable for the primary crushing or grinding of clay and minerals coming directly from quarries and for reducing its original irregular size to uniform sizes below 80mm so that the material may be properly batched and stored. Verdés crushers are specially designed to accept nonferrous minerals that ...

crushing and grinding Archives

Uralmashplant JSC has started shipping crushing and grinding equipment to the Tautejak project in Magadan Oblast, Russia. Towards the end of the September quarter, the complete set of crushing and grinding equipment to crush and grind the gold ore will be delivered to the project, Uralmashplant, part of the UZTMKARTEX Group, said.

What is a primary and secondary crusher

What is a primary and secondary crusher Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, What is a primary and secondary crusher, quarry, aggregate, and .

Latest Posts

- كسارة الفك هوبر

- رمل السيليكا تعويم آلة الغسيل

- جميع أنواع الكرة مطحنة

- طاحونة او مخطط

- أنواع آلات طحن مع السعر

- الإمارات العربية المتحدة حامل الحزام الصانع

- جنوب أفريقيا فاصل المعادن غير الحديدية

- تعاريف سحق وطحن ماليزيا

- محطم الشاشة في الربيع

- العمود الفقري آلة الحصاة

- شراء غسالة سامسونج في سري لانكا

- شراء كسارات المخروط الألمانية

- بيع خام الكوبالت VSI محطم

- صيانة كسارات الحجر الجيري المحمول في أنغولا

- Potash Crusher Hardness

- Ball Sui Le Mining

- Coal Mining Jaw Crusher

- Crushing Vibratory Feeder Jost Invest Benefit

- Zinc Oxide Processing Machine Samac

- Railroad Ballast Crusher

- Roll Crusher Titanium Sponge Samactitanium Crusher

- Concrete Belt Conveyor Side Wall Conveyor Belt Nn Conveyor Belt

- Gravel An Sand Washing Equipments

- Bond S Work Inde Ball Mill

- Mini Jaw Crusher Burkina Faso

- Ukuran Jaw Crusher Berat 8ton

- Harus Dicari Di Produsen Crusher

- Gold Separators Made In Brazil

- How To Recover Gold From Electronics

- Slate Roller Mill For Sale