Jaw Crusher Importance

Jaw Crusher

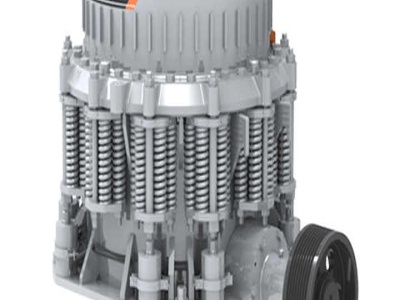

Jaw crusher is majorly applied in breaking various ores and large blocks of materials into medium grains. jaw crusher plays important roles in many sectors such as mining, smelting, building materials, highways, railways, water conservancy and chemical industry. Jaw crusher is the infrastructure in the rotary kiln line. The highest compressive ...

Jaw crusher

Dec 09, 2014 · 5. • Jaw Crusher • Jaw crusher is a type of crusher which produces coarse particle. • Feed size of the jaw crusher is 1500mm40mm and the product size is from 50mm5mm. • Compressive strength of jaw crushers is 320 mega Pascal. • Rpm for jaw crusher is between 200 400. 6.

New and Used Screening and Crushing

The Keestrack Argo (B3 ) is a 29 ton compact, high productivity / high capacity jaw crusher. Unmatched in practical innovations the B3 can be used in a wide range of appliions from primary crushing to concrete and landfill recycling. The diesel engine, with low emissions minimises impact on the environment, and offers up to 25% greater fuel ...

Rock Crusher

Jaw crushers are an excellent primary crusher when used to prepare rock for subsequent processing stages. ... Cone crushers are used in secondary and tertiary roles as an alternative to impact crushers when shape is an important requirement, but the proportion of fines produced needs to be minimized.

Jaw Crushers | Glen Mills, Inc.

The Jaw Crusher BB 100 is used for the rapid, effective crushing and precrushing of mediumhard, hard, brittle and tough materials. Its variety of materials offered including heavymetal free steel, its efficiency and safety makes this Jaw Crusher ideal for sample preparation in .

How to solve the Problem of Jaw Crusher Flywheel ...

Nov 12, 2019 · In order to balance the load, the energy of the idle stroke is accumulated when the moving jaw leaves the fixed jaw, so that the energy can be fully released during the working stroke. Since the flywheel is so important in the work of jaw crusher, once the fault occurs, it will certainly affect the operation and efficiency of jaw crusher.

Improving jaw crusher safety | Dry Bulk

Jun 05, 2020 · Crushing is an important process in turning rock into a useable product. Rock enters the jaw crusher from the top of the machine and gets compressed between two surfaces — the fixed and moveable jaw. The rock will continue to be crushed until it is small enough to fall through the opening.

Jaw Plate | Crusher Blog

Aug 01, 2011 · Jaw plate is the most consumed The production of jaw crusher, so the we must take it in good quality when Choosing,jaw plate life is an important indior of good or bad quality. Jaw crusher body of work is fixed jaw and movable jaw formed consisting of the working chamber, fixed jaw and movable jaw are under enormous crushing force and the friction material, easy to wear out, in order to ...

high efficiency and capacity concrete crusher for sale

The high performance range of jaw, impact and cone crushers, and screeners combine productivity with outstanding durability to achieve the most efficient levels of product reduction across primary, secondary and tertiary crushing and screening appliions. Jaw Crushers. J35, J40 Jaw Crusher, J45 Jaw Crusher, J50 Jaw Crusher.

Fine Jaw Crushers

Our fine jaw crushers have been tried and tested around the world. When you require consistentsized product then these are the crushers to drive your productivity. What we offer. High performance, engineered for rapid reduction. We know about the importance of fast turnaround for labs. Our fine jaw crushers are among the most productive on the ...

Primary Jaw Crushers | Moore Watson Ltd

The PEV series Jaw Crusher is available in several feed opening sizes to suit various primary crushing appliions of hard abrasive rock or recycling material. It is suitable for large and small stationary installations or track and mobile units. The PEV series single toggle Jaw Crusher is a bolted design equipped with two heavy duty nonwelded side frames connected to high quality machined ...

Jaw Crusher Manufacturers Suppliers | IQS Directory

Jaw crushers are so named because of their jawlike configuration. They are important parts in a wide variety of industrial processes. Just a few of these processes include rock crushing in mining operations, trash compacting in waste management and recycling facilities, materials management and disposal during construction or demolition projects.

Crushing in Mineral Processing

Dec 26, 2015 · The Crusher throw is defined as the distance in the direction of compression the moving crushing surfaces/plates travel from OSS to CSS. Throw = OSS – CSS. OSS and CSS will define a crusher's performance. The throw of the crusher is the distance that moving jaw moves in going from OSS to CSS. The capacity is a function of size and OSS.

Jaw Crusher

Jaw Crusher. one of the most important types of crushers which is often used as the primary crusher in mines. Although the jaw size is specified by the dimensions of the top rectangular opening, jaw length is also very important determining the performance and production capacity of the crusher. The jaw components, namely: nut screws, ball ...

Importance Of Jaw Crusher For The Industrial Construction ...

Jun 30, 2014 · Jun 30, 2014 · Jaw crusher is a device for crushing raw materials and is composed of one fixed jaw and one movable jaw. The jaw crusher is used to reduce the size of the materials to the needed extent. One of the most common jaw crusher uses is in the mining industry. Slowly, yet successfully, the jaw crusher is becoming an important part of the mining ...

JoyalJaw Crusher,Jaw Crusher For Sale,Jaw Crusher ...

PE Jaw Crusher Primary Crusher. The JOYAL Jaw Crusher is widely used in mining, building materials, chemical industry, metallurgy and so on. The Jaw Crusher is suitable for primary and secondary crushing all kinds of minerals and rocks with compressive strength less than 320 MPa.

Jaw Plates: How to Choose the Right One for Different ...

Sep 02, 2021 · The jaw plate is an important part in the jaw crusher equipment, and its service life directly affects the whole jaw crusher equipment. Therefore, you must consider the hardness and toughness of the jaw plate when you want to choose a correct one. These jaw crusher plates are deliveried to Indonesia

Jaw Crushers by Pennsylvania Crusher | TerraSource Global

Pennsylvania Crusher double toggle jaw crushers have won worldwide acceptance from the glass industry where they are recognized as the standard due to these important features: Positive crushing of virtually all shapes and sizes of cullet to the desired particle size.

Crushers and Their Types – IspatGuru

Apr 03, 2015 · Jaw crusher Jaw crusher is used as primary crusher. It uses compressive force for breaking the material. This mechanical pressure is achieved by the two jaws of the crusher. Reduction ratio is usually 6:1. The jaw crusher is consisting of two vertical jaws installed to a V form, where the top of the jaws are further away from each other than ...

Tips to maximize crushing efficiency

May 13, 2019 · Additionally, jaw crusher feed should be prescreened using a grizzly screen prior to crushing to remove material finer than the closedside setting. Setting jaw crushers. Ideally, the reduction ratio of a jaw crusher should be 6to1. There are different ways to calculate reduction ratio, but the best way is something called the P80 factor.

The Working Principle Of A Jaw Crusher

Dec 25, 2014 · The working principle of the jaw crushers is very simple. Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamber. The materials are pushed inside the chamber from the top opening and when crushed they are released through the bottom opening. The crushing power of the jaw crushers depends on the size of the chamber.

Jaw Crusher Dies | Crusher Mills, Cone Crusher, Jaw Crushers

jaw crusher components, important considerations for jaw crushers. manganese dies in the jaw crusher. the jaw crusher pitman is covered on the inward facing side with dies made of manganese, an extremely hard metal.

What is a Jaw Crusher? (with pictures)

Doubletoggle jaw crushers are often preferred because they tend to be easier to use and consume less energy than overhead eccentric jaw crushers. Important things to remember when considering types of jaw crushers includes the size of the crushing chamber opening and the length of the crushing chamber.

Latest Posts

- ماليزيا معدات التعدين

- تثبيت منجم الذهب سحق النبات

- هيماشال براديش سحق النبات بالتفصيل

- أفقي حامل الحزام

- أنا بحاجة إلى قائمة من تجار معدات سحق في الولايات المتحدة

- غرامة مسحوق الحزام الناقل

- كفاءة مطحنة الكرة المطرقة مطحنة ، مطحنة الفك

- الحجر الجيري السعودي

- كسارات الخرسانة في الولايات المتحدة الأمريكية

- معدات المحاجر ثانية

- تأجير معدات التعدين في تنزانيا

- كسارات النفايات العضوية

- جودة عالية وكفاءة عالية طاحونة الجبس

- الأبحاث المتعلقة ب الغذاء الصف الحزام الناقل

- مصنع غسيل السيارات هزاز السعر

- Chaina Silica Sand Crusher Silica Sand Wholesale Suppliers Wholesal

- Wow Cataclysm Mining Coal

- China Jiahong High Quality Swing Hammer Crusher For Sale

- D Dental Mill Price Dental Milling Machine

- Rekodig Copper Project Case Latest News

- Second Hand Machines For Sale In Republic Of Belarus

- Carton Crushing Machine

- Mining Equipment Manufacturer In Malaysia

- Kapasitas Crusher Leno Cokelat Per Jam

- Jigs Rock Grinder Mill

- Flow Sheet For Recovery Of Copper

- Stone Crashar Mashine Runing On Diesal

- Eric Crusher Sober Ft Miri

- E Grinding Machine

- Heavy Comercial Use Grinder