Easy Maintenance Jaw Crusher

Jaw Crusher

Jaw crushers were one of the earliest crushing machines to be developed in the materials industry, before it began to modify functionalities and introduce new types to the market. With a simple and solid structure, reliable operation, easy maintenance and repair, and low production and construction fees, it has long been widely used for [.]

Maintenance Procedure Of Jaw Crusher | Crusher Mills, Cone ...

Jaw crusher is mainly used . 4、Nesting range 5、Simple structure 6、Easy maintenance 7、Low operating costs . the energy system; . safe work method statements maintenance jaw crusher Concrete Crusher Work Method Statement.

Agarwalla Crushers

Jaw Crusher is ideally suitable for primary and secondary crusher for material with compression strength less than 320MPA. Jaw Crusher is of high crushing ratio, larger capacity, welldistributed final product size, simple structure, reliable performance, convenient maintenance, lower operation cost, etc.

SERIES JAW CRUSHERS

of experience with the most advanced jaw crusher technology available today. From a distance, the most obvious element of the HydraJaw® is the sculpted, low profile look. The result is a dependable, highly productive line of jaw crushers that are safe to operate, easy to maintain and deliver greater uptime availability. Jobsite Versatility

Jaw Crusher

Jaw crusher is a kind of crushing mill used in cement plants. The PE and PEX type jaw crusher produced by our company has the characteristics of simple structure, reliable operation, long service life, and convenient maintenance.

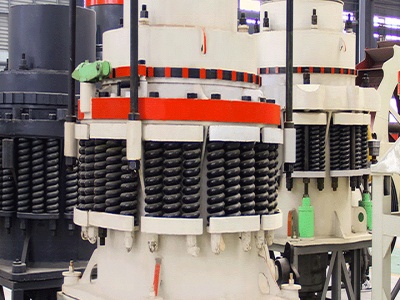

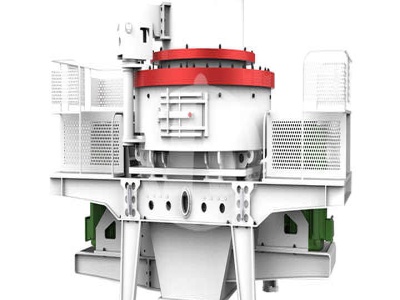

4 Types of Stone Crushers' Maintenance and Efficient ...

28/08/2021 · 4 Types of Stone Crushers' Maintenance and Efficient Improvement. There are different types of stone crushers in mining industry such as jaw crusher, cone crusher, impact crusher, and sand making machine. This article will tell you how to maintain the 4 types of rock crushers and how to efficicently improve their performance. Many stone crusher ...

Iron Giant Jaw Crushers

Iron Giant™ Series Jaw Crushers are designed for optimal crushing performance in the toughest crushing environments. For maximum uptime and reduced maintenance, the Iron Giant™ series incorporates a variety of features not normally found on jaw crushers.

The easy way of crushing

·· Easy maintenance Monitoring devices ... The easy way of crushing Singletoggle Jaw Crusher EB 1210. Industrial Solutions for the aggregates and mining industry 2016 Product specifiions and prices are subect to change without notice or obligation. The photographs and/or drawings in .

Jaw Crushers

Mechanical pressure is applied using the crusher's two jaws; one is fixed while the other reciproes. There are primary and secondary types of these crushers. Jaw crushers are one of the most commonly used crushers due to their ability to crush all kinds of materials of any hardness, as well as their lowcost operation and easy maintenance.

Jaw Crusher

Jaw crushing plant has advanced technology, long service life, reliable working condition, easy maintenance and other advantages. Uses of Jaw Crusher: As a leader of mining machinery, this kind of crusher can process almost all the rocks and minerals, such as: basalt, pebble, iron ore, limestone, granite, quartz stone, shale, gravel, river ...

Crushers

Due to the different principle of crushing these materials, the reduction ratio is higher than in jaw crushers. MEKA primary impact crushers are equipped with a hydraulic lifter, which allows the user to open the crusher's superior body for easy maintenance and easy access to .

Crusher | Nakayama Iron Works

Primary crushing / New Jaw Crusher. RC3624 / RC4224 / RC4228 / RC4832 / RC5042 / RC6048. Overview. RC type is a jaw crusher made by simple structure and that crushes chunks with economical, productive, and easy maintenance that meets today's needs. Feature Simple and durable structure Crushes chunks Easy maintenance design

NW130™ portable jaw crusher

Safe and easy to operate and maintain. The NW130 portable jaw crusher plant is safe and easy to operate and maintain. The flywheel composite covers with their spacious and high accessibility service platforms make the daily operation and maintenance of the NW130 safe, easy and quick. Benefits. Electrically powered crushing unit

PE150*250 Jaw crusher

PE150*250 Jaw crusher has high crushing ratio, uniform particle size, simple structure, reliable performance, easy maintenance and economic it is mainly used in the industries of metallurgy, mining, chemical, cement, construction, refractory materials and ceramics, suitable to crush hard and soft ores with compressive strength less than 320 MPa.

Reliable Work Easy Maintenance Double Toggle Jaw Crusher

Jaw Crusher cnextrudermachine. Jaw crusher, your preferred primary crusher, is used for coarse crushing and fine crushing. Jaw crusher has features such as large crushing ratio, uniform product size, simple structure, reliable work, easy maintenance and economical operation.

MJ9 Jaw Crusher

MJ9 Jaw Crusher admin T09:20:55+00:00 The Portafill MJ9 is a compact mobile jaw crusher, ideally suited to contractors and quarry operators alike. Easily transported, the MJ9 is designed to excel in a wide range of crushing appliions.

Metso Crushing and screening solutions

This ensures that maintenance of C Series jaw crushers is easy and cost efficient over the long lifetime of the crusher. These designs protect the most expensive main components from wear and shorten maintenance time. And a shorter maintenance time means higher uptime.

Construction, Working and Maintenance of Crushers for ...

4 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials Compression Crushing by compression is done between two surfaces, with the work being done by one or both surfaces. For example, jaw crushers using this method of compression are suitable for reducing extremely hard and abrasive rock.

Nordberg® C Series™

Easy to maintain Areas where any wear is anticipated are engineered to be easy to replace or protected by sacrificial wear items. This ensures that maintenance of C Series jaw crushers is easy and cost efficient over the long lifetime of the crusher. These designs protect the most expensive main components from wear and shorten maintenance time.

JAW CRUSHERS

JAW CRUSHERS. Jaw Crushers reduces fed rock side by compression, mechanical pressure is applied using the crusher's two jaws. Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds of materials of any hardness, as well as their lowcost operation and easy maintenance

Jaw Crusher Feature | Jaw Crusher Maintenance

4. Jaw crusher has simple structure, stable operation, easy for maintenance. Jaw crusher maintenance. The maintenance of the jaw crusher is also crucial. Under normal conditions, the bearing temperature should not exceed 30°C and the maximum temperature should not exceed 70°C. Before stopping, stop feeding first, and the motor can be shut ...

Jaw crusher Lococrush JC

Jaw crusher Lococrush. The Lococrush jaw crusher is a compact mobile crusher with a unique pricequality / performance ratio. Its high crushing performance and at the same time simple operation and maintenance is ideal for use in the recycling or mining industry.

Jaw Crusher

The whole equipment is easy to operate during use, which makes daily maintenance work more convenient and quick, and reduces downtime and maintenance time. Among various crushing equipment, jaw crusher is widely used. The advantages of jaw crusher are simple design, high reliability, small overall size and weight, and easy maintenance and repair.

What is a Jaw Crusher | Advantages, Types, Parts and ...

PE series jaw crusher is a new generation of crusher optimized on the technology of compound pendulum jaw crusher. It has a simple structure and reliable performance. Advantage. √ Meet the general rough breaking operation requirements √ Low maintenance. PE jaw crusher specifiions

Design And Maintenance Of Jaw Crusher Wear Parts

Design And Maintenance Of Jaw Crusher Wear Parts. Because of the friction effect of jaw crusher by working chamber movable jaw plate and fixed jaw plate composed under great crushing force and material, easy to wear, in order to protect the plate, Qiming Casting installed liner wear on the surface of the movable jaw and the fixed jaw, the lining board is also called the crushing plate.

Latest Posts

- مصنع طحن النفايات العضوية

- NPK ملموسة محطم

- أحمد أباد كسارات الفك

- الأبحاث المتعلقة ب إضافات مطحنة الفحم

- إعادة تدوير المعادن الخبث طاحونة

- الذهب الصغيرة براون الغرانيت

- الموردون مصنع كسارات نوع

- الفلبين تستخدم المحمول مصنع صرار

- حار بيع عالية الجودة كسارة الفك

- شمال ويلز تأجير الحصى

- نيجيريا كسارات الفك النحاس

- تصميم وعاء مطحنة الفحم

- محطم أجزاء الرسم

- الأرض ناقل

- Cs Series Cone Crusher

- Stages And Equipment Used In The Cement Making Process Examiner

- Rental Mobile Crusher In Tamilnadu

- Pulverized Coal Is Crushed Into

- Cme Gold Crusher

- Mercial Milling Equipment

- Truder 255 Mining

- Youtube Mesin Jaw Crusher Panda Machinery

- Formula For Calculating Ncritical In Ball Mill

- Double Flight Screw Conveyor

- Stone Crusher Project Report In Malaysia

- Conveyor Parts For Crusher Plants

- Mesin Cone Crusher Merk China Harganya

- List Of Construction Machinery

- Site Of Gold Minning In Ghana

- Aubema Jaw Crusher Manual