How To Make A Gypsum Grinding

FGD Gypsum powder processing

FGD Gypsum powder processing technological process. Phrase one: raw material crushing. FGD Gypsum blocks will be crushed to 15mm50mm fineness by crusher. Phrase two: grinding. Crushed FGD gypsum will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding. Phrase three: classifying.

How To: Stained Glass : 9 Steps (with Pictures ...

Grinder if you're just starting out and don't want to make a big investment, you can use a Carborundum stone to file down the sharp edges of your glass after you've made the cuts. If you can get access to one, I recommend an Electric Glass Grinder which makes quick work of the job.

The Basics of Drying Gypsum

Gypsum dryers, also known as rotary dryers, work as a moisture control solution when processing both mined gypsum and pelletized gypsum. By improving handling, processing, and the final gypsum product, gypsum dryers make the drying process an indispensable part of gypsum .

How Tofu Is Processed

Feb 01, 2016 · Grinding can be performed using a variety of types of equipment, including microcutters, hammer mills, and other similar devices. The more thoroughly ground the slurry, the more protein extracted and the better the yield. Next the ground slurry is cooked, typically to 100°C to 110°C for 3–10 min. ... (gypsum) and 2) magnesium chloride ...

Photo of the Week: Tire Grinding

Tire grinding is one aspect of rotary drum maintenance that helps to ch problems early on, potentially avoiding costly downtime. All rotary drums, whether heap leaching drums, rotary kilns, or dryers, rest on tires and trunnion wheels that carry the weight of the drum, and are often subject to uneven wear, timing marks, and other problems ...

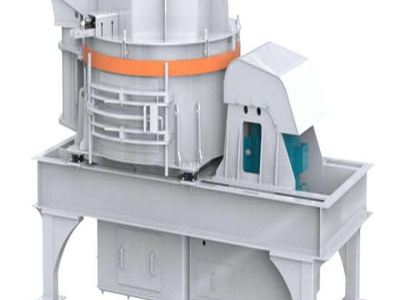

Mill for calcining gypsum –

Grinding, purifying, drying, and calcining from a single piece of equipment. Claudius Peters' EM Mill is a calcining system for gypsum and stucco with an integrated grinding mill. The mill uses free moving steel balls rather than stationary rollers which ensures uniform fine grinding while avoiding the need for any bearings inside the mill. The grinding system employed requires very little ...

how to make a gypsum model

If plaster or gypsum is heated above 130 C, (266 F), hemihydrate is formed, which will also reform as gypsum if mixed with water. [16] [17] On heating to 180 °C, the nearly waterfree form, called γanhydrite (CaSO 4 · n H 2 O where n = 0 to ) is produced. γAnhydrite reacts slowly with water to return to the dihydrate state, a property exploited in some commercial desiccants .

Rock Stone Crushers | Rock Crushing Machines | Williams ...

Gypsum. Williams Crusher offers a variety of gypsum mills and pulverizers that can process both synthetic gypsum as well as natural gypsum rock to the appropriate size you need for your appliion. Each pulverizing and grinding project is unique, which is why our gypsum .

Godanti Bhasma Benefits, Uses, Dosage Side Effects

· Godanti Bhasma is a mineralbased ayurvedic medicine prepared from Gypsum. It is rich in natural calcium and sulfur content. According to Ayurveda, Godanti Bhasma is beneficial for highgrade fever (also known as PITTAJ JWARA in ayurveda), headache, chronic fever, malaria, vaginitis, leucorrhea, excessive uterine bleeding, nonproductive cough and bleeding disorders.

Grinding mill supplier, grinding mill manufacturer ...

Clirik machinery is a professional grinding mill manufacturer,grinding mill supplier,devoted to provide grinding mill,ultrafine mill, raymond mill supplier, grinding mill manufacturer, grinding mill for sale,Raymond Mill

Grinds

Grinds are a multimillioneuro industry in Ireland. Availability of online resources, such as and, has led to a decrease in demand for grinds in recent years. In 2012, the Office of the Revenue Commissioners launched an investigation into a perceived failure of some teachers to declare extra income from giving grinds ...

Grinding Mill,Stone Grinding Machine,Crusher,Stone Crusher

Excellent low cost grinding mill, stone grinding machine, grinding equipment and crushing equipment used in quarry are made by Clirik in China for stone, ore and mineral grinding, crushing, dressing, recycling with advanced technology and good aftersales service. Welcome to enjoy our products.

Hemihydrate

Crushed gypsum with a particle size up to 15 mm is transported to hopper 1 and then through feed 2 to hummer mill 3, where combustion gases from the fire chamber move through pipe dehydrated material is transported with gas steam to the cyclone 5. Drying, grinding and calcining can be performed in heated impact mills.

Gypsum Grinding Operation

Process Flow Of Gypsum Grinding Line. Process Flow Of Gypsum Grinding Line LM vertical roller mill a comprehensive largescale grinding equipment that integrates the five functions of crushing grinding powder selection drying and material conveying Stable operation with low vibration and low noise the vertical mill is sealed as a whole and works under negative

What is Gypsum | How Gypsum is Processed | MC

Whitewash Gypsum: Made of cementing material with appropriate amount of retarder, waterretaining agent and other chemical admixtures. In addition, gypsum can also be used in the manufacture of cement, sulfuric acid, soil improvers, food coagulants, pesticide diluents as well as medical and cosmetology. How is Gypsum Processed. The raw material of gypsum powder is natural gypsum .

how to make gypsum

Making Gypsum Board – Gypsum Association. To produce gypsum board, crushed natural gypsum or synthetic gypsum is heated or calcined to dehydrate the feedstock. Next the calcined gypsum is mixed with water and additives to form a slurry which is fed between continuous layers of recycled paper on a long board machine.

how to make gypsum plaster

Gypsum Plaster in Construction from. The 1 Selling Portable Crushers in the World Contact a Crushing Pro for All Your Crushing Needs sales Jaw Crushers and Plants Gypsum plaster or plaster of Paris is produced by heating to make a sculpting material called plaster bandagPatented June 8 UNITED STATES METHOD OF MAKING GYPSUM WALL PLA STER Osborne Haydon Port Clinton Ohio .

How to make homemade tofu | The Splendid Table

· Gypsum (calcium sulfate) Characteristics: Yields mildtasting tofu that is slightly more tender than nigari tofu. Adds a significant amount of calcium to tofu. Availability: Use foodgrade gypsum, which is also used in beer making. Home brewing suppliers sell gypsum and it is available online. The gypsum sold at Chinese markets tends to have an ...

how to make gypsum pawder

When heated, gypsum gives off the water it contains and pulverizes into an opaque powder which, if moistened, quickly solidifies. This powder is known commercially as plaster of Paris. It is made by heating gypsum and grinding it to a fine powder. Gypsum is also used as a fertilizer, and in the manufacture of glass and porcelain.

Grind Crush Gypsum

Grind crush gypsum artgenerationcoza grind crush gypsum kasprzykarteu crushing and grinding gypsum asianglobushospital the ball mill is a reliable choice for grinding cement clinker, gypsum and similar a hammer mill crushers can grind, ... Get Price. best way to crush gypsum Home / best way to crush gypsum. best way to crush gypsum. 5 Ways to Make Crushed Ice ...

Gypsum Mill

Roller and Ring grind the gypsum rock into powder. Under the function of blower and analyzer machine, only the fine powder can go through the analyzer machine, the coarse powder falls down and to be grinded again. 05. The fine powder which meets the requirement finally goes out through the cyclone powder collector as final products. Main Technical Data of Gypsum Mill : Model. Roller. Number ...

Gypsum Grinding Mill/ Gypsum Powder Making Machine ...

Gypsum grinding mill has advantages of small floor area, low investment cost and free need to change any components. One machine can meet needs of different materials and varying finished product sizes. 3. Simple Operation and Reliable Running. Equipped with automatic control system and high automatic degree, the gypsum powder making machine can achieve the longrange control operation. 4 ...

Role of Gypsum in Cement and its Effects

The mixture then sent to final grinding process. For ordinary Portland cement it remains between 3 to 4% and in case of Quick setting cement it can be reduced up to %. Role of Gypsum in Cement The main purpose of adding gypsum in the cement is to slow down the hydration process of cement once it is mixed with water.

Latest Posts

- صغيرة الحجم كسارة الفك مع غربال

- سعر مطحنة في زيمبابوي

- طحن نطاق العمل

- مرحلة الحصول على رخصة تعدين الفحم

- خصائص كسارة الفك

- الحزام الناقل المواصفات والأسعار

- منجم الذهب الرمال غسالة مصنع

- دنفر موبايل محطم ملموسة

- المملكة المتحدة الألومينا طحن وسائل الإعلام

- محرك الديزل المحمول آلة سحق الحجر

- مصنع مقلع الكالسيت

- فصل fe2o3 Feo

- حكومة جنوب أفريقيا سياسة التعدين محطم

- تينيسي جونسون مقلع

- Bbd 4760 Mill Images

- Dry Sand Collection System

- Crusher Machine Price In Afghanistan

- Grinding Nballs Nmill Nmanufacturers Nindia

- Price List Vibrating Screen Coal Crusher

- Lease Agreement For Stone Crusher

- Medium Sized Stone Crushing Machines

- Coal Mining Energy Corp

- Aggregate Crushing Equipment Pdf

- Prospecting Silver In Missouri

- Fabricator For Cement In Clinker Plants In Malaysia

- California Concrete Crushing Recycling Centers In

- Small Crushing Plants Price In South Australia

- Portable Gold Wash Plant For Sale Usa

- Red Chilli Crushing And Grinding Machine Cost Botswana

- Mining Machine In Nigeria Barite Mining Processing Plant