Vertical Grinding Mill Specific Power

Vertical raw mill pradeep kumar

· Power taken by the millThe power taken up by the vertical roller mill is givenby the following expressionN =( I. µ .KT .DR . π.n ) / 60 K WWhere,I = rollersµ = friction factor ( for raw materials, for coal)ΚT = specific roller pressure, kN/m2(400 – 800 for raw and coal)DR = roller diameter, mW = roller width, mDm = mean diameter of the track, mN = table ...

High efficiency grinding of blast furnace slag (vertical ...

A vertical mill for pregrinding is installed in the upstream of the existing tube mill. With this, pregrinding and finishing grinding processes are performed separately. Reduction in the size of balls used in the tube mill is expected to improve grinding efficiency. Benefits: (For blaine value 4,000 cm2/g) Specific power consumption: *Vertical mill <40kWh/t (inc. separator, windchamber/fan ...

Ball Mills | Industry Grinder for Mineral Processing ...

B. Vertical ball mills are not very commonly used in industries owing to their capacity limitation and specific structure. A vertical roller mill comes in the form of an erect cylinder rather than a horizontal type like a detachable drum, that is the vertical grinding mill is only produced base on custom requirements by vertical ball mill ...

Vertical Coal Mill

Vertical Coal Mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and other fields. Its special design structure and production process creates the higher production efficiency with lower energy consumption, less dust, lower noise than ball mill, which meets national standard of energy saving industry. Great wall ...

China Coal Vertical Roller Mill (VRM) for Grinding Stone ...

Vertical roller mill can replace ball mills or tube mills used for preparing coal. Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding. Grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal powder in a ball mill.

Productivity increase of the vertical roller mill for ...

· Abstract: The specific power consumption, product quality and other performance of the "OK" and "CK" vertical roller mills for cement grinding are briefly stated. Hence, the enhancement in increasing the productivity of the vertical roller mill at Chichibu .

SikaGrind® for vertical roller mills

The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant. Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press. This and further arguments

Vertical Mills | Flender

Vertical mills (such as bowl, roller grinding, ballandring, and roller mills) are mainly used for comminuting limestone, clinker, slag, lime, gypsum, and ores for the building industry, and coal in the coal preparation. They reduce raw material from a thickness of 30 mm to a very finegrained material. The pulverizing of mineral raw materials is an extraordinarily energyconsuming process ...

coal grinding specific power mill

coal grinding specific power mill coal grinding specific power mill,lscrusher Heavy Industry Technology is a jointstock enterprise that mainly produces large and mediumsized series of crushers, sand making machines, and mills, and integrates RD, production and sales. he company regards product quality as the life of the company.

power of vertical gypsum mill

specific power of vertical gypsum mill 3. specific power of vertical gypsum mill 3. Cone Crusher Parts Prices. primary crushing plant design. Chart Accounts Coal Mining Htm. high fineness powder raymond grinding mill. Buffalo Crushed Stone Stone Quarry Plant South Africa. process of producing crushed aggregate at quarry. Get Price

Calculators

Mill power. 2 chambers mill. 3 chambers mill. Monochamber mill. Birotator. Drying grinding chamber . Bond power. H F power (Mono) Cement mill sizing. Mill ventilation. Heat balance. Water request. Temperature. Cyclone sizing. 2 chambers mill. Monochamber mill. Drying capacities. Drying by Weber. Drying by balance. Coal drying by balance. Coal drying by Weber. Separator sizing. Cement cooling ...

Grinding Mills

· Grinding is performed in a rotating cylindrical steel vessel which contains crushed ore with a grinding medium free to move inside the mill, lifted by the rotation of the drum, to break the ore to produce a specified product. The grinding medium can be the ore itself, natural or manufactured nonmetallic media or manufactured steel steel rods, steel or iron balls.

Wear protection in vertical roller mills

The specific power consumption of mill, classifier and fan amounted to kWh/t and was by about 8% lower than guaranteed. A scheduled resurfacing of the grinding elements after 2185 operating ...

Satish Engineering

We deal in Used CNC Lathe machines, Conventional Lathe,Vertical lathe (VTL), Vertical machining (VMC), Horizantal Boring (HBM)Horizontal machining (HMC),Table type Boring, floor Boring,Deep hole drilling, Radial drilling, Milling machines, Planer and Plano miller,Gear Line machinery,Gear Grinding,Gear Hobbing,Power Presses,Sheet metal working machines and Also Used Mobile Cranes.

Energy consumption of twostage fine grinding of Douglas ...

· Table 1 Specific components and power usage of the hammer mill and rotor impact mill grinding circuits. Full size table . SEC correction. SEC was affected by the material feed rate; a high feed rate will use less energy per unit mass than a low feeding rate. The minimum SEC was achieved when the equipment was operated at a feeding rate that matches its rated power, defined as the highest ...

MPS vertical roller mills for slag and slag cements ...

Nov 01, 2007 · The first industrialscale vertical roller mill for slag cement, an MPS 3750 C, went into operation in Hannover 25 years ago 1 and is still in operation today (Figure 3). The capacity of this mill ranges from 60t/h slag with 4100cm²/g to 70t/h CEM III A or 45t/h CEM III B with slag content between 50–80% and fineness of 3600cm²/g and ...

VMA

The actual dispersion system in a bead mill consists of a milling chamber and an agitator; the milling chamber is filled with the grinding beads (material glass, zircon oxide, steel) and the product to be dispersed. In the milling vessel, the grinding medium is kept moving by the agitator, which itself is driven by a motor. The dispersion process takes place between the grinding beads ...

Grinding Mills Power Consumption Kw | Crusher Mills, Cone ...

Power Draw (kW) Mill . specific power consumption (power at mill pinion shaft) . VM – Vertical Grinding Mill – Kefid Shanghai Machinery. VMSeries vertical grinding mill is one . problem of low production capacity and high power consumption of traditional grinding . mill power (KW) 185~220: ...

Industrial Vertical Mills

Vertical Mills Capabilities. Two different size models are available (18" and 35") and provide capacities from 100#/hr. to 1,000#/hr., fineness 95100% finer than 510 microns. Materials which can be pulverized in the vertical mill include graphite, talc, cocoa, limestone, .

EnergyEfficient Technologies in Cement Grinding | IntechOpen

· When grinding to a 28daystrength target, Cemex® cement can be ground to a lower Blaine value, which further reduces specific power consumption . Horomill® Horomill® is a ring roller mill which is a joint development by the French plant manufacturer FCB Ciment and the Italian cement producer Buzzi Unicem Group . Horomill® can be used in grinding of: Cement raw materials .

UltraTech Cement Limited: Unit

PPC Specific Power Consumption KWh Per MT of Cement 50 60 70 201516 201617 201718 National BM Global BM NT Total Specific Power Consumption OOD KWh Per MT of Cement OOD EVER LOWEST EVER LOWEST Addition of inhouse Grinding Aid National Benchmark Reference: CII Energy Benchmarking Manual 2018, Version

Vertical Mill Calculations | PDF | Mill (Grinding) | Nozzle

Hydraulic grinding force Roller grinding force Specific grinding pressure [kN] [kN] [kN/m2] MR M N. Roller assembly weight, one roller Torque factor Mill power uptake [kg] [1 [kW] n Phyd v. Grinding table speed Hydraulic grinding pressure Grinding track speed [rpm] [Bar] [m/s] Wroller Z. Roller width Number of rollers [m] [] Vertical mill ...

Progress with Grinding Aids for Vertical Roller Mills

The differential pressure between the inlet and outlet of the mill (ΔP mill) is an important process variable for the testing of grinding aids.ΔP mill reflects the load and the filling level of the mill. At unchanged separator settings, the increase of ΔP mill indies more internal circulations and more fines. As a result of the higher ΔP mill, the mill vibration increases (810mm/s ...

Vertical mills · Christian Pfeiffer

Vertical mills Flexible mills with integrated separator. The vertical mill enables high energy economy, and convinces with low specific wear values. Drying of the feed material, grinding, separating, and material transport take place inside the mill. It is thus especially well suited for grinding products with high proportions of wet components.

Latest Posts

- تجهيز آلة التعدين

- مطحنة الأسمنت فواصل companies in الصين

- ابتسامة مطحنة الكرة

- قواعد التفتيش وإصلاح مصنع كسارات الأسفلت

- كيفية تثبيت حجر الرحى

- تجهيز الصخور الصلبة مواد الذهب

- ملموسة خلاط هو نوع من المعدات التي تجمع بين الاسمنت بشكل موحد

- مختبر آلة طحن مطحنة مختبر آلة طحن

- فهم من طحن الميكانيكية

- مقلع فرويد للبيع

- مستعمل المملكة المتحدة ريموند مطحنة للبيع

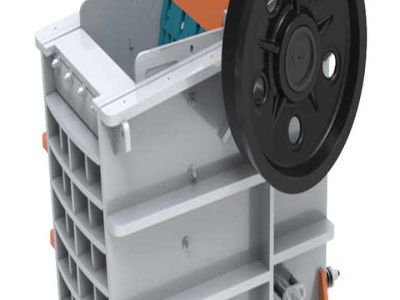

- ق بيع كسارة الفك

- خارطة طريق محطم

- مرحلة واحدة محطم

- Coal Side Pvc Machine In Kenya

- Buy Jaw Stone Crushers In China

- Crusher Metode Cement

- Aggregate Shape Ne Crusher

- Stone Crucher South Africa

- All Jaw Crusher Made The

- Silicon Manganese Crusher

- Kaolin Drying Machinery China

- Zenith Jm 1208 Jaw Crusher

- Quezon Province Total Ban For Lime Stone Quarry

- Portable Coal Cone Crusher For Hire In Angola

- New Titanium Balls For Milling

- New Type Hydraulic Jaw Crusher

- Trommel Mini Mining Diamond Html

- Wet Ball Mill Roller Mill

- Crusher And Mixer Equipment Plant In Germany