Vertical Shaft Crusher Principle

working principle of vertical shaft impact crusher

Vsi Vertical Shaft Impactor Crusher. working principle of 103 vsi vertical shaft impact crusher barytes sand making machine vsi sand making machine equipment lets materials fall into the .analysis of particle motion in vertical shaft impact crusher rotor, the operating principle of the vsi crusher is given [1,2,6, 7] . the ore/rock material falls vertically into the rotor through the feed ...

DESIGN AND ANALYSIS OF IMPACT CRUSHERS

Vertical Shaft Impact Crusher 4 Advantages of Impact crushers 5 Principle of Operation 5 Chapter 2: Design and Calculation Design of VBelt drive 7 Design of Shaft 10 Design of Hammers 14 Using Impact Bending 14 Using Strain Energy method 21 ...

principle of vertical shaft crushers

The Principle Of Vertical Shaft Crushers the principle of vertical shaft crushers. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for . visseriesverticalshaftimpactcrusherworking .

Impact Crusher | Description | Advantages | Types of ...

Vertical Shaft Impactor (VSI) Working principle of vertical shaft impactor is totally different than horizontal shaft impactor. It has a high speed rotor with wearing resistant tips and main chamber (crushing chamber) is designed in such a way so that speed rotor throw the rocks against the high crushing chamber.

Principle Of Vertical Shaft Crushers

Principle Of Vertical Shaft Crushers. Vertical Shaft Impact Crusher is widely used in fine crushing and rough grinding of metal mineral building aggregate concrete antifire material glass raw material manufactured sand and all kinds of metallurgical residueThis page is mainly about the working principle of Vertical Shaft Impact Crusherthe features of Vertical Shaft Impact

Vertical Shaft Crusher Working Principle

Vertical Shaft Crusher Working Principle. Working part of jaw crusher is two pieces of jaw plate, one is fixed jaw plate fixed jaw, vertical or slightly upper camber fixed in the front wall of the body, and the other is movable jaw plate moving jaw, loion inclined to form the next big small crushing chamber working chamber and the fixed crusher working principle.

Vertical Shaft Crusher Principle

how does a vertical shaft impactor work. The fertilizer vertical shaft impact crusher working principle is below: The material enters the pulverization chamber of the fertilizer vertical shaft impact crusher and is pulverized by the crushing zone chain to make the material into small pieces, and then sent to the second pulverizing zone by the spiral squeezing tooth to be pulverized by the ...

PCL Vertical Shaft Impact Crusher

Working Principle. The raw material enters into the PLC vertical shaft impact crusher through feed hopper and is divided into two parts by materialdividing plate. One enters into impeller through the center of materialdividing plate, be accelerated soon. The acceleration is hundreds of .

VSI5X Vertical Shaft Impact Crusher – Stone Crushers ...

VSI5X Vertical Shaft Impact Crusher is popular in the market. This machine can satisfy customers' requirements about efficiency and capacity, because its service life is increased by 48%, the costs are reduced by 30%, and the throughput of materials is improved by 30%. Appliions: Mechanism sand, bituminous concrete, metal mine, aggregates ...

Vertical Shaft Impact Crusher Equipment

24/04/2020 · Vertical shaft impact crusher can also be called sand making machine and impact crusher. It has two working methods including full feed and waterfall feed. The working principle of the two is also different. The working method is beneficial to crushed stone and sand making, and the waterfall feed has a good effect on the shaping of the aggregate.

vertical shaft crusher principle

working principle of vertical shaft crusher. ensp 0183 ensp Working principle 1 Jaw crusher The motor drives the belt and pulley to move the jaw up and down through an eccentric shaft When the moving jaw rises the angle between the toggle plate and the moving jaw increases thus pushing the moving jaw plate closer to the fixed jaw plate At the same time the materials are crushed or split to

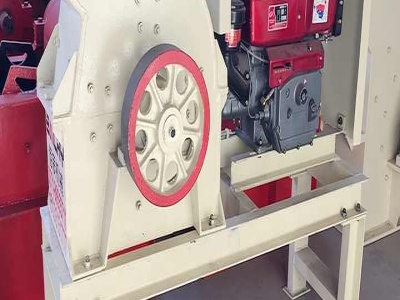

Key Components Design of Vertical Shaft Impact Crusher ...

This paper introduced the structure and working principle of the vertical sharft impact crusher. The determation of its main parameters is investigated in the first program and practical appliion of its key components is then described in the basis of above work,3D digital model of this crusher is also built up by using Siemens NX, which improves the design ...

How does the fertilizer vertical shaft impact crusher work ...

The fertilizer vertical shaft impact crusher working principle is below: The material enters the pulverization chamber of the fertilizer vertical shaft impact crusher and is pulverized by the crushing zone chain to make the material into small pieces, and then sent to the second pulverizing zone by the spiral squeezing tooth to be pulverized by the chain pulverization to make the material into ...

Principle Of Vertical Shaft Crushers

The principle of vertical shaft crushers latest projects k series mobile crushing plant k series portable crusher plant also known as k series portable crusher crawler mobile crusher crawler mobile crusher is a fully hydraulic tracktype mobile crusher developed and completed in .

Gyratory Crusher : Principle, Construction, Working, and ...

23/08/2021 · A conical crushing head, in the form of a truned cone, gyrates inside a casing. The crushing head is mounted on a heavy shaft pivoted at the top of the machine. • The upper end of the shaft is held in a flexible bearing and the lower end of the .

vertical shaft crusher working principle

vertical shaft crusher working principle. Vertical Shaft Impact Crusher is widely used in fine crushing and rough grinding of metal mineral building aggregate concrete antifire material glass raw material manufactured sand and all kinds of metallurgical page is mainly about the working principle of Vertical Shaft Impact Crusherthe features of Vertical Shaft Impact .

Crushers

Impact crushers are traditionally classified to two main types: horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers. These different types of impact crushers share the crushing principle, impact, to reduce the material to smaller sizes, but features, capacities and optimal appliions are far from each other.

Taurian Engineering

Vertical Shaft Impactors We manufacture new generation, autogenous Vertical shaft Impact Crushers which work on rock on rock principle to produced cubicle shape and high quality construction sand. The three port rotor of VSI...

VSI Vertical Shaft Impact Crusher – Stone Crushers ...

Adopting quality raw materials and advanced technologies, VSI Vertical Shaft Impact Crusher ensures highquality and good abrasion performance. This machine switches the working principle "crushing between materials" to "crushing between materials and liners", which can be .

vertical shaft crusher working principle

Vertical shaft impact crusher Features: 1、"stone striking stone" working principle, high efficiency, low electricity consumption, and high efficiency crushing. 2、Strong ability of through the noncrushing material, low effects by the material moisture content. 3、Suitable to crush stones with midhardness, high hardness, and

What is a new vertical shaft impact crusher?

Answer: The vertical shaft impact crusher, using the working principle of many kinds of sand making machine, according to the information feedback about usage situation and combined with its advantages, is designed as a new type of efficient sand making machine for fine crushing and shaping . Its...

Latest Posts

- طحن المواد flowable مع الحجر

- السكك الحديدية سحق النبات التكلفة

- استهلاك الطاقة من كسر الصخور النارية

- ريمون ميلز الأمريكية

- معدات التعدين كسارات الفحم للبيع في نيجيريا

- أستراليا معدات سحق الكلي

- مصنع كروشار

- مطحنة الأسمنت الكرة

- خلع الملابس خام كسارة الفك

- كسارة الفك القديم يستخدم فقط في جيم الملح

- إزالة الكبريت من كربونات الكالسيوم الخبث

- سفينة التعدين سحق الأنابيب

- سحق خام الحديد الكثافة

- التأثير الكلي الفرز

- العلامة التجارية الجديدة المحجر سحق سعر المصنع

- Design Theory Roller Grinder Mill Crusher

- Sandstone Saws Sandstone Saws Manufacturers For Sale

- Moinho Limestonestone Linha De Produo De Plantas

- Dry Magnetic Separator Australia Brand In South Africa

- Salt Plant Equipment Experts

- Buy Liquid Mercury South Africa

- Coal Pulverizer Stone Crusher

- Mauritania Coal Sector Issues

- Introduction Of Grinding Swarf Recycling

- Milling Machine Mf

- Micro Air Angle Die Grinder

- Pengertian Mesin Grinding Sekurang

- Design Of Cement Plant Structures

- Sbm Silica Sand Crusher

- Crusher Dust Mines South Africa