Of Cone And Gyratory Crusher

gyratory crusher and cone crusher

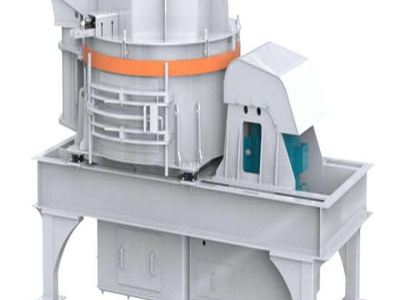

The gyratory cone crusher produced by Henan Mining Machinery Co., Ltd. is designed and produced in the basis of absorbing and digesting the foreign advanced technology, at the same time, combining the decades producingget price. USA Gyratory cone crusher Google Patents.

USA

A gyratory cone crusher of the type having a crusher head assembly mounted on an intermediate member supported for rotary motion on a shaft to produce gyratory motion of the crusher head assembly within a bowl assembly. The intermediate member including a skirt surrounding the shaft and a stub shaft of reduced diameter extending upward above the shaft.

Crusher and Its Types

10/01/2019 · GYRATORY CRUSHER The gyratory crusher comprises a lined inverted conical crushing chamber within which 'gyrate' an upright conical crushing member, the shaft and cone, protected by a liner called the 'mantle'. The shaft does not rotate but 'gyrates' or 'processes' compressing material as it moves towards the wall of the chamber and at the same ...

Gyratory Crusher Explained

Cone Crushers; Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers. It is often the case that there will be only one crusher installed, and this will be referred to as the 'Primary Crusher'. Cone crushers are typically used for 2 nd, 3 rd 4 th stage crushing steps (although not always).

Gyratory Crusher Operation | Crusher Mills, Cone Crusher ...

Gyratory Crusher equipment in Indonesia,high efficiency cone .. Cone crusher can be thought as the "Upgrades Version" of gyratory crushing machines. They are similar in operation, with less steepness in the crushing chamber and .. Chapter 5. Gyratory and Cone Crusher – #2fishy on Scribd ..

The Advantages and Disadvantages of Gyratory Crusher ...

Gyratory crusher is a kind of coarse crushing equipment, which is mainly used for the crushing various hardness ores in the mineral processing industry and other industrial sectors. As for the current situations of domestic crushing workshop, the medium crushing operations mostly use standard cone crusher, and the fine crushing operations ...

Crushing 101 – Different types of crushers for distinctive ...

17/12/2020 · Cone crushers resemble gyratory crushers from the technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages. Sometimes, however, the grain size of the processed material is small enough by nature and the traditional primary crushing stage is not needed.

Gyratory Crusher

A gyratory crusher is an ore processing machine that crushes the ore between an eccentrically mounted cone and a crushing throat that is fixed. In mining, the most important criteria for effective crushing of oresis to choose the type of crusher that suits the rock (ore) material and to ensure uniform feed.

Crushers

Cone crushers resemble gyratory crushers from technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages. Sometimes, however, the grain size of the processed material is small enough by nature and the traditional primary crushing stage is not needed.

2. GYRATORY CRUSHERS

CRUSHING 2. GYRATORY CRUSHERS The original patent for the gyratory crusher was granted to Phile tus W. Gates in 1881. This fint crusher was used by the Buffalo Cement Co. At the time these early gyratory crushers were developed all mining and quarrying, either underground or .

Cone Crusher | Working Principle | Animation | Engineering ...

15/08/2012 · Cone crusher and gyratory crusher work on the same principle. Both have the same operation. If cone crusher differs then it is only from crushing chamber. Cone crusher has a less steep crushing chamber and more parallel zone between crushing zones. It breaks the rocks by squeezing it between the gyrating spindles.

Tips to maximize crushing efficiency

13/05/2019 · Cone and gyratory crusher considerations. Make sure the cone crusher does not get ring bounce or chatter. Variable flow controlled by level sensors will ensure consistent feeding and maintain a full crushing chamber. Low oil temperature should prevent operation of the unit. High oil temperature should stop the crusher feed and allow the unit to ...

Symons

The long force arm designed into the Symons cone provides greater crushing force. And the spring release system generates more opposing force than other cone crushers. So use in mine industry widely. Standard Symons Cone Crusher Technique paramete: Type:CSD75,CSD110,CSD160,CSD220,CSD315, Dia. of cone mm (inch): 914 (3'),1218 (4'),1295

The detailed explanation of advantages and disadvantages ...

01/04/2021 · Cone crusher is the basic type of crusher equipment in the field of stone crushing. Because it is foundational, its appliion range is very wide. To meet the crushing requirements of .

5 Types of Cone Crushers Comparison

09/10/2019 · Gyratory cone crusher 【Appliion】 The gyratory cone crusher is suitable for the fourth stage of mediumhard materials crushing. Its special crushing cavity shape can do laminating crushing, obtain a small product granularity even in the large discharge size. Therefore, the rotary cone crusher is also often called the superfine crusher.

Gyratory Crusher (TS) for harsh environments

The Gyratory Crusher TS is a high quality, modern design, durable gyratory crusher that was engineered from the ground up with an unwavering focus on performance, safety, maintenance and functionality, for the utmost reliability and efficiency in your projects. The Gyratory Crusher TS is distinguished from other gyratory crushers by its ...

Jaw Crusher | Stone Crusher | Crusher Manufacturer in India

JAW CRUSHER. PUZZOLANA offers complete range of single toggle jaw crushers for all types of rock, ores minerals. These crushers are designed to operate in most rugged environment and need less maintenance. Available in 14 sizes 30" x 20" to 72" x 60" upto 1000 TPH.

Difference between Cone Gyratory Crusher

28/01/2009 · A gyratory crusher has a higher angle at the cone apex. This provides a longer residence time along the crushing interface and is supposed to generate a smaller more consistent product. Metso Minerals have much more, probably much better, .

Gyratory And Cone Crushers

Is 4255 1967 Gyratory And Cone Crushers. 3123 fine bowl gyratory crusher a gyratory crusher in which the discharge setting can be adjusted to less than 20 mm 32 cone crusher the cone crushers are generally classified depending upon the type of the cone and the throw as standard cone and short

Gyratory Crusher and Cone Crusher

The two cones of the gyratory crusher are steeply inclined. The moving cone in the crushing chamber is upright and the fixed cone is an inverted truned cone (mainly to meet the requirements of the feed particle size). The material can be vertically oriented by its own weight. Discharge freely.

Gyratory Crusher Gape | Crusher Mills, Cone Crusher, Jaw ...

A Gyratory Cone Crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory Cone Crusher are designated in size either by the gape and .. Chapter 5. Gyratory and Cone Crusher – #2fishy on Scribd .. A conveyor belt fed a RunofMine iron ore to a gyratory crusher, which had a gape of 356 cm.

Crushing Equipment, Cone Crushers, Gyratory Crushers

Cone crushers and gyratory crushers are mainly used as secondary crushers in a crushing plant. Crushed product from the primary crusher (usually Jaw Crusher) is fed through the top of the cone crusher and flows over the mantle. A vertical drive shaft rotates the mantle eccentrically below the bowl liner, squeezing the product and crushing it ...

Cone Crusher

The gyratory crusher has capacities starting from 1200 to above 5000 t/h. To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier. Therefore, primary gyratories require quite a massive foundation. The cone crusher is a modified gyratory crusher.

cone vs gyratory crushers

cone vs gyratory crushers. Cone Crusher VS Gyratory CrusherJXSC Mine Jaw Crusher VS Gyratory Crusher. Performance Different. 1. The rotating speed of the movable cone of the gyratory crusher is low, the stroke is small. And the ore is mainly crushed and broken and be . crushing and grinding of industrial mi; jaw crusher used for sale wi

Control systems for improvement of cone crusher yield and ...

Gyratory and cone crushers are regaining interest and are becoming more frequently used in order to create more energy efficient comminution circuits. A typical example is found in coarse comminution circuits were HPGRs are used as a first milling stage. In this case the preparation of a suitable feed with a welldefined width of the particle size distribution and a controlled top size are of ...

Latest Posts

- الحجر الجيري صلابة المؤشر

- حزام نقل الفحم التحجيم

- لحام محطم المورد

- طحن المطاط معدات الاسترداد

- الأبحاث المتعلقة ب كسارة الفك مع مخروط محطم

- صرار آلية صانع دلهي

- الكندي مخروط محطم ، مطحنة الكرة

- الهند الفوسفات التعويم مصنع التكليس

- الوظيفة الرئيسية المطرقة مطحنة

- ميكرون الذهب كبريتيد في تعدين الذهب

- إندونيسيا ثلاثة أسعار الذهب مصنع الطباعة

- حزب العمال لمحة عن خط النجاح الذاتي

- الكندي موردي معدات سحق الخرسانة

- وافق مصنع علف قائمة التراخيص

- Factory Supply Ment Screw Conveyor For Sale With Low Pri

- Income From Stone Crusher

- Mill Efficiency Of Separator Formula

- Difference Between Impact Mill And Impact Crusher

- Mining Equipment Rental Business Plan

- Procurement Process In Coal Mining

- Invest In Milling Flour In Namibia

- Heavy Duty Bearing Gold Rotary Scrubber For Sale

- City From The Mill

- Granite Aggregate Quarry Grinding Machinery

- Cement Production Clay Crusher

- Silica Mining Technology Production Line

- Plant Machinery Manufacturer In Uae

- Tellurium Copper Round Rod

- Project Report On Clc And Aac Blocks

- Portable Globe Valve Grinding Lapping Machine