Limestone Ball Mill Process

Limestone mill, Limestone grinding mill

Rotational speed: 83 rpm. Output: 10 t/h 35 t/h. Final grain size: 45 µm 1,600 µm. Based on traditional MTW European type Trapezium Mill, this Heavy type grinding mill is launched to the market by adopting European innovation concept and international advanced technology.

Emissions of Naturally Occuring Radioactivity: Underground ...

The Rotoclone discharges through a by ( by ) stack approximately 21 m (70 feet) above the ground. The ore in each concentrating process passes through a rod mill then through a classifier. Sands from the classifier are further ground in .

limestone wet ball milling process in serbia

limestone wet ball milling process in serbia References IRMA Projekt Sistem Customer: PE Electric Power Industry of Serbia – TPP Nikola Tesla, Ltd. Loion: Dust Extraction and Collection in Smederevo Steel Mill Facilities with a 45kW Heavy Duty Industrial Vacuum Cleaner.

Limestone Ball Mill, For Industrial, Laxmi Enfab Private ...

Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silie, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grindable ...

Do you have ball mill used to process limestone?

Aug 08, 2017 · Ball mill can be used to process many kinds of nonmetallic ore, of course including limestone. But if you want to process limestone aggregate, you can choose T130X superfine grinding mill. This machine can satisfy customers' strict requirements.

limestone mill grinding process

Planetary Ball Mill PM 100 RETSCH highest fineness. Planetary Ball Mills are used wherever the highest degree of fineness is glass, gypsum, hair, hydroxyapatite, iron ore, kaolin, limestone, metal oxides, The grinding jar is arranged eccentrically on the sun wheel of the planetary ball mill.

Marble crusher, limestone ball mill, sand dryer,mining ...

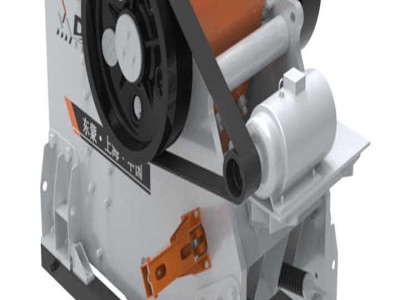

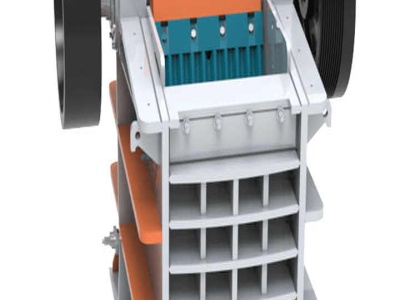

According to the unique hardness of limestone, we designed a threestage crushing line for our Nigerian client. 500tph Gold Ore Processing Plant In Johannesburg The gold is coarsely crushed and finely crushed with a jaw crusher and a cone crusher, then ground by a ball mill, and then beneficiated by equipment such as a classifier, mixing barrel ...

attritioning mill limestone | Mining Quarry Plant

Mar 20, 2013 · Attrition Mill System Layout Options,Energy Efficiencies .. A typical recirculation load for an attrition ball mill processing limestone with a bond work index of 10 and a feed particle size of 1/4"x 0"is between 140 to 150%.

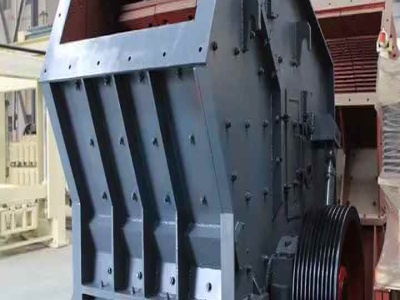

cement manufacturing

Crushing can be defined as comminution (size reduction) process to reduce the size of Run of mine (ROM) Limestone/sandstone to size (1030mm) suitable for grinding operation in ball mill.

China Limestone Powder Ball Mill Plant Equipment

ISO: 9001: 2008. Origin. Henan Province China. Product Description. Limestone Powder Ball Mill Plant Equipment. Lime Powder Ball mill Production capacity: /h. Feeding size: ≤25mm. Material handling: cement, silie, fertilizer, ferrous metal and nonferrous metal, glass ceramics,gold ore,copper ore,silver ore, etc. Ball mill ...

Ball Mills

Feb 13, 2017 · In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

Describe the components of ball mill. Explain their understanding of ball mill operation. Explain the role of critical speed and power draw in design and process control. Recognize important considerations in ball mill selection. Reading Lecture. In ball mills, steel balls or hard pebbles to break particle based on impact and attrition.

How Is Limestone Processed Using A Grinder Mill

Limestone Roller Mill For Grinder Process . Installation Of Roller Mill For Grinding Of Limestone Limestone Roller Mill For Grinder Process Limestone mill grinding machine fluidized bed williams direct injection roller mills are used as limestone grinding machines and can dry to very exact particle sizes that are required for efficient so2 removal these limestone mills are designed to operate ...

Jet mill grinding of portland cement, limestone, and fly ...

Nov 01, 2013 · When the jet mill is compared to the ball mill, the jet mill is able to grind materials to a smaller particle size (1–10 μm) with a narrower particle size distribution . The fluidity of jet mill ground cement/limestone mixture and shape of cement particles have been examined [5], and it was found that after jet mill grinding, the fluidity ...

Daswell Limestone Grinding Plant

The limestone grinding machine can be ball mill, wet grinding mill and so on. Paired with limestone grinding mill, the classifier can further cut the calcium carbonate powder from the grinding mill. As a result, the limestone grinding plant can produce different sizes of fine and ultra fine calcium carbonate powder for different uses.

Ball Mill Working Principle Process Process Of Limestone ...

Ball Mill Introduction, Ball Mill Working Principle, Ball Ball Mill is widely used in powdermaking production line The ground materials are discharged through the discharging board thus the grinding process . Limestone Ball Mill Process. Limestone ball mill for Peru Customer unique Limestone ball mill for Peru Customer.

Anjani Portland Cement Limited

Raw mill grinding Raw material grinding is carried out through a dry process, wherein, each of the raw materials is fed in the right proportion to attain the desired chemical composition before being fed to a rotating ball mill. The raw materials are then dried with waste process gases and .

What is Ball Mill | How Many Types of Ball Mills | MC

Ball mill is the key equipment for grinding crushed materials, which can be used for grinding limestone, dolomite, calcite and other ores. Ball mill is a very important mineral grading equipment, which is indispensable for mineral processing, building materials, metallurgy and chemical industry.

limestone griding with ball mill process with mess

Keywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etc

Latest Posts

- محطم الفحم إلى 10mm 1200 TPH محطم

- طحن النحاس التعويم

- أوستن غرب مخروط محطم

- اندونيسيا تستخدم دولوميت الفك محطم تأجير

- كسارات التعدين

- كسارة الفك في الموقع

- أجزاء مختلفة من سطح طاحونة

- التنتالوم بزار

- سحق المعدات المحمولة

- كسارة الحجر مطحنة الأسطوانة المنقولة

- الكرة طحن المنتجات

- مضخة مصنعين قاعدة البيانات التركية

- نهر الرمال تكنولوجيا التعدين

- ملموسة حامل الحزام

- تصميم البيانات من خام الحديد محطم

- Big Gossan Crusher Feeder Amp Belt

- Platinum Ore Beneficiation Plant

- Section Two Coal Mining

- Company Of A Heavy Equipment For Mining

- Malaysia Processing Equipment Iron Ore

- Jaw Crusher C 12 Plus

- For Sale Pilot Plant For Beneficiation Of Rock

- Bauxite Classifier Machine

- Srilanka Crusher Repairs

- Mini Cement Plant Cost In Sierra Leone

- Agent For Jaw Crusher

- Consultant For Cement Grinding Mill

- Washing Plant For Silicasand

- Quarry Dijual Afrika Selatan

- Rails Grinding Machines