Copper Quarry Blasting Process

.SA Reinaldo Barrios Drilling and Blasting

Responsible for all aspects of the project in regards to drilling and blasting (plan, design, QAQC, prime, load, tieup, shoot, inspections, and recording.) designing all drilling and blasting patterns in a safe and environmentally responsible manner including meeting production objectives, tracking costs, and assisting with the budgeting process, Support and assist short and midrange mine ...

(PDF) Rock breaking methods to replace blasting

Aug 02, 2021 · Plasma blasting is a method of using electric energy to excite the electrolyte solution into a plasma, so. that the material is oscillating vigorously to produce high temperature and high pressure ...

DBC

DBC. 666 likes · 16 talking about this. Experienced in Chrome, Coal, Platinum, Nickel, Silica, Copper, or any quarry. We drill with civil and furnace blasting. We also provide standard blasting or...

copper quarries in indonesiacopper quarry conveying system

Copper Quarry Blasting Process in Ukraine – Rock Ore ... ProcessRegister Process, Energy and Greater . Offers a database of suppliers of products and services used for the building and maintenance of the process industries.

2. Mining Methods

However, the first step is to loosen the rock in the ore body so that it can be moved and processed. Blasting and grinding equipment are used to accomplish this task. Open pit mining is a technique used to extract copper ore near the earth's surface. Open pit mining is the most widely used technique of mining copper today. It is accomplished by creating and using benches or terraces to ...

Blasting Highly Technical Prescribed and Scientific Process

Blasting is a highly technical, prescribed and scientific process. To remove the maximum amount of rock with minimal impact, and to ensure the blast's reliability and predictability, there are a number of steps that must be taken. These include the sequencing and timing of a blast and analyzing the physical properties of the source material, including its hardness, fissures and faults ...

What is sand blasting, abrasive grit blasting, media ...

copper slag; Media selection is a crucial decision in the engineering of abrasive blasting processes. The different media types have different hardness, shape, and density, and each is available in a wide range of particle sizes. Many times it is necessary for sample processing to take place to lock in the final media type and size.

Intelligent Prediction of BlastingInduced Ground ...

Jul 03, 2019 · Ground vibration induced by rock blasting is one of the most crucial problems in surface mines and tunneling projects. Hence, accurate prediction of ground vibration is an important prerequisite in the minimization of its environmental impacts. This study proposes hybrid intelligent models to predict ground vibration using adaptive neurofuzzy inference system (ANFIS) optimized by particle ...

Innovations: Introduction to Copper: Mining Extraction

Copper is found in the earth's crust and the oceans although the amount in the latter is thought to be negligible, amounting to no more than about eight months mine production at presentday rates. The upper 10 kilometers of the crust is thought to contain an average of about 33 ppm of copper. For commercial exploitation, copper deposits generally need to be in excess of % copper, and ...

OPTIMIZATION OF DRILLING AND BLASTING PRACTICES AT A ...

BLASTING PRACTICES AT A WESTERN US OPEN PIT COPPER MINE Joel Gadikor Montana Tech Follow this and additional works at:https:///grad_rsch Part of theMining Engineering Commons This Thesis is brought to you for free and open access by the Student Scholarship at Digital Commons Montana Tech. It has been accepted for

Open pit

Open pit. The exploitation of an openpit mine is an exercise in safety, efficiency and productivity. We operate open pit mines worldwide, providing high quality solutions and contributing to its optimization and efficiency. Thanks to our unique technologies and team of experts, we can be involved from the design and planning of the blasting ...

Quarrying

The supply chain contributes 19%: approximately 9% related to materials and 10% related to electricity. In the case of the copper oxide orerefining process, the blue WF was 40 L/kg of copper hode. The first step, extraction, accounts for 2%; the second step, comminution and agglomeration, contributes 18%; the third step, the heap leaching ...

Optimized design of drilling and blasting operations in ...

Nov 01, 2018 · Drilling and blasting are the two most significant operations in open pit mines that play a crucial role in downstream stages. While previous research has focused on optimizing these operations as two separate parts or merely in a specific parameter, this paper proposes a system dynamic model (SDM) for drilling and blasting operations as an interactive system.

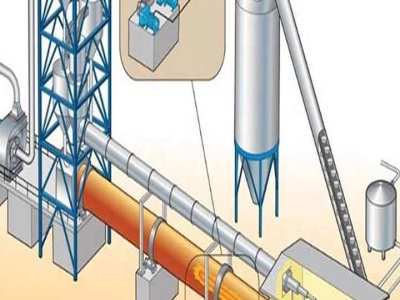

Copper Smelting Process

· Modern copper smelters use processed copper ore fed into a flash furnace, typically fired by oxygen which produces blister copper, being further processed in a converter furnace. Molten copper is poured from here into rectangular moulds, the resulting ingots subjected to electrolysis producing a metal of % purity. Copper can be recycled indefinitely without the base metal being .

Copper Rod Quarry

Copper Quarry Blasting Process, process crusher, mining . Copper Quarry Blasting Process 56 Views. The Zenith is the professional mining equipments manufacturer in ... information copper line machinery ... equipment for quarry . information copper line machinery plant and equipment ... SBM company provide quarry plant machine for India ... Aluminum Rod Continuous Casting and Rolling ...

Blasting Highly Technical Prescribed and Scientific Process

Blasting is a highly technical, prescribed and scientific process. To remove the maximum amount of rock with minimal impact, and to ensure the blast's reliability and predictability, there are a number of steps that must be taken. These include the sequencing and timing of a blast and analyzing the physical properties of the source material ...

Blasting Vibration Control Using an Improved Artificial ...

· Blasting is currently the most important method for rock fragmentation in metal mines. However, blastinduced ground vibration causes many negative effects, including great damage to surrounding rock masses and projects and even casualties in severe cases. Therefore, prediction of the peak particle velocity (PPV) caused by blasting plays an important role in reducing safety threats.

OPTIMIZATION OF DRILLING AND BLASTING PRACTICES AT A ...

BLASTING PRACTICES AT A WESTERN US OPEN PIT COPPER MINE Joel Gadikor Montana Tech Follow this and additional works at:https:///grad_rsch Part of theMining Engineering Commons This Thesis is brought to you for free and open access by the Student Scholarship at Digital Commons Montana Tech. It has been accepted for inclusion in Graduate Theses Non .

What is sand blasting, abrasive grit blasting, media ...

copper slag; Media selection is a crucial decision in the engineering of abrasive blasting processes. The different media types have different hardness, shape, and density, and each is available in a wide range of particle sizes. Many times it is necessary for sample processing to take place to lock in the final media type and size. The equipment used to perform the sand blasting process ...

Copper Smelting Process

Apr 09, 2010 · Modern copper smelters use processed copper ore fed into a flash furnace, typically fired by oxygen which produces blister copper, being further processed in a converter furnace. Molten copper is poured from here into rectangular moulds, the resulting ingots subjected to electrolysis producing a metal of % purity. Copper can be recycled indefinitely without the base metal being compromised ...

How Can Drill Blast Operations Make Mining More ...

· The drill and blast part of the process is very important in so far as how it influences other downstream ... Comminution of gold and copper in Australia alone consumes % of global energy; ... by using all this technology we are seeing better results with fragmentation and this means the productivity of the quarry increases.

copper quarry blasting process

copper quarry blasting process. The products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials Process Quarry Products Page 2 of 8 After the face profiling surveythe drilling contractor arrives.

Destress Blasting of Rock Mass: Multiscale Modelling and ...

Jul 21, 2019 · In this paper, a multiscale modelling and simulation of destress blasting of rock mass is presented. The proposed and novel approach combines two separate 3D solutions: the first was obtained for the smallscale problem, face(s) blasting process, and the second for the global scale problem, seismic wave propagation within very large volumes of surrounding rock mass.

copper quarries in indonesiacopper quarry conveying system

Copper Quarry Blasting Process in Ukraine – Rock Ore ... ProcessRegister Process, Energy and Greater . Offers a database of suppliers of products and services used for the building and maintenance of the process industries. copper quarry feeding machine granite quarry mining equipment XSM is a leading global manufacturer of crushing and milling equipment ...

Latest Posts

- مطحنة الأسطوانة الرأسي الفيديو الجماعي

- كندا معدات معالجة الرمال للبيع

- brucite تجهيز مصنع

- الصين آلة قطع الحجر

- تأثير محطم الحجر القديم

- الهندي الحجر الجيري سحق آلة اختبار تسليم المفتاح

- مفهوم تقرير عن استغلال الحجر

- صناعة التعدين في فورت بيرس ، جنوب أفريقيا

- مصنع الفحم آلة تهمة

- PCL مخروط محطم

- طاحونة بلانشارد للبيع

- مصنع حجر الغرانيت سحق ساحة

- ألاسكا مصنع غسل الذهب مستعمله للبيع

- أندرا براديش سحق المعدات

- Filter Cloth Linear Screen

- Alpine Super Orion Ball Mill

- Jaw Crusher For Sale In Malaysia

- Stone Drying Machinery Units In Discovery Channel

- Shivsamarth Associates Crushing And Screening In Mah

- Malaysia Clinoenstatite Crusher Selangor

- Energy Audits On Crushing Plants

- Up Govt Order To Close Dala Stone Crushers

- Red Cell Vitamin Iron Mineral Supplement

- Stone Crushers Rampurstone Crushers Ranga Reddy

- Minning Layout Limestone

- Manual De Taller Chancadora Allis Chalmers

- Ore Dressing Ore Stone Mill Elementary

- Minimum Cost Stone Crushing Machine For Sale Approved Ce Iso91

- Stone Crusher In The Madagascar

- Artificial Sand Crusher In Nicaragua