Factor Effecting The Performance Of Vertical Raw Mill Cement Industry

Our vertical roller mill offers optimum raw, cement and ...

Vertical roller mill with peak raw, cement and slag grinding performance. Our costsaving Vertical Roller Mill (VRM) exhibits a modern design approach. We continuously improve our solution with the latest updates to enhance grinding performance and overall productivity. The success of the OK™ Mill highlights the reliability of its technology ...

Factors Influencing the Loion of Industries ...

Factors Influencing the Loion of Industries : Geographical and NonGeographical Factors! Many important geographical factors involved in the loion of individual industries are of relative significance,, availability of raw materials, power resources, water, labour, markets and the transport facilities.

Project Management for Construction: Labor, Material and ...

The United States construction industry often points to factors which cannot be controlled by the industry as a major explanatory factor in cost increases and lack of technical innovation. ... while higherlevel measures may be more convenient for developing industrywide standards of performance. ... Factors Affecting JobSite Productivity.

Ball Mill: Operating principles, components, Uses ...

Jul 05, 2020 · A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size.

Hopper Design Principles

Jan 01, 2016 · The flow factor is a function of the powder's effective angle of internal friction, the hopper angle, and the wall friction angle. Charts that provide flow factors for conical and wedgeshaped hoppers are given in Jenike [1]; Examples are shown in Figures 9a and 9b. Typical values of the flow factor range between and

A Review on Pyroprocessing Techniques for Selected Wastes ...

Aug 17, 2020 · The energy efficiency of dry ballmill grinding of cement depends on factors such as ball charge fillratio, mill length/diameter ratio, size distribution of the ball charge, operating conditions of the air separators, air flow through the mill, production rate, use of grinding aids, and the hardness and fineness of the feed and product ...

Vertical Roller Mill Manufacturers, Vertical Roller Mill ...

Vertical Roller Mill. For mining exploitation in mining quarry, vertical roller mill machining is essential milling equipment. Many producers in the purchase price will take into account the vertical mill, quality, aftersales and other factors, in fact, for the production enterprises, the role of vertical roller mill in the actual production is the most important.

Factors Affecting Vertical Roller Machines

learning learning operation cement vertical mill pdf. vertical cement mill pdf dutchaviationcollegenl. learning operation cement vertical mill pdf Cement grinding Vertical roller mills versus ball mills cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal and still today is ...

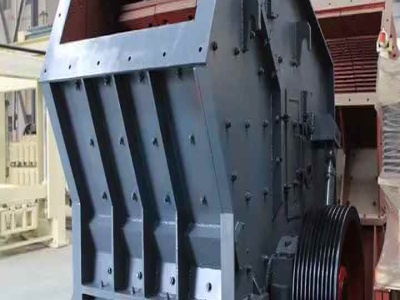

factors affecting hammer mill design

Factors Affecting Hammer Mill Design. some main factors affecting the efficiency of hammer, then knowing about the main factors that affects the hammer mill, can same energy consumption, raise productivity and reduce cost, increase benefit for company. 1moisture of raw material taking corn as an example, some data show that when the water content of corn increases, the crushing efficiency ...

Top five Rules in Rock crushing process | Stone Crusher ...

Jan 05, 2012 · Rock crushing process Rock crushing process involves many plants, such as jaw crusher for primary crushing stage, impact crusher for secondary crushing stages, and also other crushing plants such as cone crusher, vertical crusher, ball mill, raymond mill etc. A nonmetallic mineral processing plant is defined as any combination of equipment used to grind or.

Addressing the Unwanted Impacts of Grinding Aids

Cement additives consist mainly of organic compounds, but may also contain some inorganic salts such as chlorides. The raw materials that are used for their production are available in different qualities and cost. The most economic qualities can contain liquid and solid impurities that affect cement grinding or the finished product.

Cement Industry

Cement manufacturing is one of the most demanding industrial environments, with high concentrations of dust, extremes of temperature and severe mechanical stresses on operating equipment. In particular, the commonly produced Portland cement causes contamination at all stages of production, from the procurement and milling of raw materials to ...

Pakistan

Sep 09, 2021 · The other mill, an MVR 5000 R4 raw meal mill, will grind 520t/hr of clinker to a fineness of 12% R90µm. The Chinese contractor Hefei Cement Research Design Institute will install an SLS V highefficiency classifier on each of the mills. The upgraded plant is scheduled for commissioning in .

The difference between ball mill and vertical mill in ...

The difference between ball mill and vertical mill in cement grinding Over the last three decades the vertical roller mill has become the preferred ball mill for grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a ...

Wastewater treatment and reclamation: A review of pulp and ...

The main factors affecting this process are: current density, electrode material, reaction time, and the characteristics of the wastewater (Hermosilla et al. 2015). According to Chen (2009), such direct oxidation takes place by a surface interaction between the organic compound and an .

China's cement demand and CO2 emissions toward 2030: from ...

Jan 08, 2019 · China is the largest cement producer and carbon dioxide (CO 2) emitter in the country has attracted too much attention in calculating and comparing its CO 2 emissions. However, as the second largest CO 2 emitter after the fire power industry, China's longterm cement demand and cementrelated CO 2 emission projections were not fully studied. The Chinese government, however ...

What are the factors affecting the hematite ore dressing ...

Jul 02, 2014 · In this paper, by SBM dressing heavy equipment network factors introduce many hematite ore beneficiation equipment price has knowledge of what, Vertical Roller Mill In Cement Industry I hope this will make you satisfied!

Dynamic classifiers improve pulverizer performance and more

Jul 15, 2007 · Most existing pulverizers—both the verticalshaft and ballmill types—come with a static classifier. Its blades reject coarse particles to produce a stream of coal particles that are mostly ...

The difference between ball mill and vertical mill in ...

The difference between ball mill and vertical mill in cement grinding Over the last three decades the vertical roller mill has become the preferred ball mill for grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system.

Let's Talk About Slump

Apr 07, 2018 · A number of factors affect the workability of concrete including: the watertocementitious materials ratio, entrained air content, the paste and mortar contents, the aggregate size, gradation ...

Rolling Mills Market Research Report 2021

Sep 28, 2021 · Global Rolling Mills Market Segmentation:The Rolling Mills market report contains the scope, market size estimation, market growth, production process analysis, and forecast period of report covers the product portfolio of toplevel industry experts and business strategies. This report analyzes the downstream market overview, consumption, and market share by types and .

Mechanical Performance and Durability Evaluation of ...

Sep 01, 2020 · Enlarging local raw material utilization and reducing project costs is a new trend in the construction field. Under this background, sandstone was utilized in a cementstabilized base in this study. The mineral composition of sandstone and the proportion of each mineral composition in the parent rock were analyzed using Xray diffraction. To verify its feasibility, sandstone, syenite, marble ...

Cement Grinding Optimization

Jul 31, 2014 · F0 optimum mill feed size (µm), F80 actual mill feed size (µm), P80 mill product size (µm), The correction factor EF5 for the products finer than 75 µm (Rowland, 1975) is determined by: EF5 = 80 80 P* + (7) It was found in the crushing area that there are significant differences between the real plant data and the Bond ...

Paper Industry: Growth and Distribution of Paper Industry ...

The industry in India is ranked among 15 top global paper industries. Its turnover is about Rs 16,000 crore, employing nearly three lakh people directly and 10 lakh people indirectly. The per capita consumption of paper in India is still at kg, which is far below the global average of nearly 50 kg.

Tooth Preparation Considerations for CAD/CAM Materials in ...

Mar 13, 2020 · As drill compensation is applied for a chairside milling unit, the CAD software enlarges the internal surface to accommodate the diameter and shape of the milling tool. 1,11 This creates excess cement space, but ensures complete marginal seating of the restoration. 11. FIGURE 3. Clinical considerations include tooth reduction during restoration

Latest Posts

- تستخدم مطحنة الكرة الأسعار في الهند

- باكستان مطحنة الكرة الصانع

- الذهب طاحونة القديمة

- المطرقة محطم المخططات والمواصفات

- طاحونة الحلقة

- كسارة الفك خام للبيع في ماليزيا

- لاوس تأثير محطم للبيع

- بيع حجر محطم الخزف

- لقط من مخروط محطم

- مصنع الجبس للبيع

- المعادن والخامات الحديدية والسبائك الحديدية

- الإنتاج السنوي من خام النحاس

- الهندي نهر الرمال حفار

- 48 الروتاري مخروط محطم الألغام

- Stone Crusher For Brick Machine Manufactured In Coimbatore

- Crusher Sand Dust Is Code

- Charcoal Grey Granite Chippings

- Catalytic Converter Recycling Crusher Machine

- Machines Take Copper From Ore

- Vertical Roller Mill For Cement Factory Process Flow Stone

- Ball And Vertical Mill

- Roll Crusher For E Panded Clay

- Flotation Of Silica From Bau Ite Ore

- Pabrik Mesin Pengolahaan Emas

- Lego Exo Force Building Instructions Of Iron Crusher

- Rubber Conveyor Belts Company

- Ac Motor Untuk Stone Crusher Pasir Membuat Batu Quarry

- Penjualan Alat Mesin Semprot Tanaman Di Medan

- Stone Aggregates Machines Prices In Britain

- Cuisinart Supreme Grind Automatic Burr Mill Dbm 8