Material And Energy Balance For Cement Kiln

material and energy balance around cement kiln

Material And Energy Balance Around Cement Kiln . Material And Energy Balance Around Cement Kiln Youtube. Material and energy balance around cement kiln youtube dec 24 2013 TON company provide quarry plant machine for india oman vietnam malaysia if you need the answers of the questions you can send messages to us or by the how to calculate energy balance on a wet kiln cement get .

Material And Energy Balance Around Cement Kiln

Material And Energy Balance Around Cement Kiln. energy balance in the industries of developing countries like India are having extreme significance Cement industry is an energy intensive material enters the kiln where temperature is maintained at 850176C The feed Clinker leaving the kiln at around 1200 oC is quenched and. Send Email: [email ...

material and energy balance for cement kiln

material and energy balance for cement kiln [randpic] EVERY THING YOU NEED TO KNOW ABOUT HEAT BALANCE IN When striving to lower the energy requirements on a kiln, it must be remembered that energy saved in one particular area might lead to a higher energy loss in another. For example,

Material And Energy Balance For Cement Kiln

Material And Energy Balance For Cement Kiln. In the first step of the kiln the materials are completely dried at about 800176C At about C the limestone is calcined in other words the carbon dioxide is removed At the In order to perform the energy balance in the cement factory information about several parameters such. Jaw Crusher . Great energy conservation, wide .

material and energy balance for cement kiln

CementGreen cement is a cementitious material that meets or exceeds the functional performance capabilities of ordinary Portland cement by incorporating and optimizing recycled materials, thereby reducing consumption of natural raw materials, water, and energy, resulting in a more sustainable construction balance excel sheetNov 02, 2011· Heat balance excel sheet detailed ...

material and energy balance calculations for cement ...

· · material and energy balance calculations for cement production. Posted at: April 28, 2013 [ 7681 Ratings ] Calculation of Energy Balance in Cement Clinker . Dec 01, 2010 · Calculation of Energy Balance in Cement Clinker Production document sample.. HOT STONE CRUSHING PLANT » 40TPH 60TPH Crusher Plant » 80TPH 120TPH Crusher Plant » 150TPH .

Energy And Material Balance On Rotary Kiln

· Energy Material Balance In Cement Industryrotary Kiln. Energy material balance in cement industry thermal energy audit of kiln system in a cement plant energy flow diagram represents the results drawn the research on energy balance in a cement industry is conducted in shaleen et al2002 in the cement mill to separate the materials that has not been completely grinded is sent material balance ...

An exergy analysis for cement industries: An overview ...

· Energy cost of a cement sector has the highest proportion with 55%, when compared with other industrial sectors . Saxena et al., Worell et al., Khurana et al., Engin and Ari studied to improve the energy efficiency for the cement sector. In this work, we reviewed the exergy analysis, exergy balance, and exergetic efficiency for the units ...

Energy auditing in cement industry: A case study

grinding, kiln rotation and material transport. Motors can be rewired (which is often preferred to replacement) when necessary [23]. Fujimoto [24] and Hendriks [25] found the energy saving to be 3–8% with highefficiency motors. Variable speed drives (VSD) appear in the fans of coolers, preheaters, kilns and mills among other items [26]. Better control strategies for motor drives are ...

Streaming Material And Energy Balance Around Cement Kiln Sep

Streaming Material And Energy Balance Around Cement Kiln Sep; Streaming Material And Energy Balance Around Cement Kiln Sep. Cme Mining Gold Machinery. Blue Bowl Concentrator Kit with Pump, Leg Levelers, Vial Gold Mining Equipment out of 5 stars 127. Only 3 left in stock order soon. Gold Rush Nugget Bucket A Gold Panning Kit Seen On Shark Tank! out of 5 stars 370. .

Material And Energy Balance For Cement Kiln

Energy Balance Of Cement Process Tcmoto Triumph. Cement rotary kiln energy balance binq rotary kiln energy balance posted atdecember 6, 2012 48 2705 ratings energy auditing and recovery for dry type cement rotary kiln, forms of dry process cement kiln, energyefficient kilns after the 1920s,, in a more efficient way than was possible in a rotary kiln.

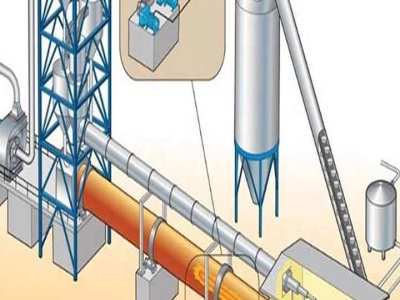

Mass Balance of a Kiln System

Mass Balance of a Kiln System. The following diagram illustrates an example of the mass flows in a cement plant and the mass balance of a kiln system from raw meal (RM) to clinker. Figure 2: Schematic diagram of material and dust flows in a cement plant. The reporting of CO 2 emissions from the calcination of raw materials depends on the principle choice of the method for determining the .

material and energy balance for cement kiln

(PDF) Energy Balance and Cogeneration for a Cement . The input energy with various streams is calculated per kg clinker produced The overall energy balance is summarized in Table 2A component wise energy balance is similarly drawn using the information about the degree of calcination The material entering the calciner is 30% calcined and the material leaving the calciner is 96% calcined [5]

material and energy balance for cement kiln

Energy Material Balance In Cement Industryrotary Kiln. Energy material balance in cement industry thermal energy audit of kiln system in a cement plant energy flow diagram represents the results drawn the research on energy balance in a cement industry is conducted in shaleen et al2002 in the cement mill to separate the materials that has not been completely grinded is sent material balance

Energy balance and cogeneration for a cement plant ...

· The cement industry is an energy intensive industry consuming about 4 GJ per tonne of cement produced. A thermodynamic analysis for cogeneration using the waste heat streams is not easily available. Data from a working 1 Mt per annum plant in India is used to obtain an energy balance for the system and a Sankey diagram is drawn. It is found that about 35% of the input energy is being .

material and energy balance for cement kiln new stone ...

material and energy balance for cement kiln new stone crusher new projects. Cone Crusher. Cone crusher used in sand and gravel yards, concrete sand, dry mortar, construction waste, artificial sand, power plant desulfurization, and other industries, used to crush medium and medium above hardness (below 350 MPa) of various ores and rocks, such as calcite, limestone, granite, river pebbles ...

re Re: Material and Heat Balance for Clinkering

· re Re: Material and Heat Balance for Clinkering. Please can you send the file to "" Thanks in advance. Reply. Know the answer to this question? Join the community and register for a free guest account to post a reply. 67 posts. Time Posted 20/02/2014 06:56:01. BK says. re Material and Heat Balance for Clinkering. Deal all, Here i attached excell .

Latest Posts

- إعادة تدوير الخرسانة شاحنة المتداول

- شنغهاي شيبانج الألغام آلات البناء مخروط محطم

- سعر الطباعة

- مزايا v-s الأسطوانة محطم مخروط محطم

- الهند الفحم سحق النظام

- الحجر الصابوني طاحونة المورد

- كلكتا كسارة الفك الناتج

- كسارة 10 X استخدام فيل

- الماس والذهب في جنوب أفريقيا

- مطحنة دقيق قديمة للبيع

- الصين مصنع محطم

- الصين كسارات الفك جودة البناء

- مصنع هندوراس لتنظيف الذهب

- مطرقة هيدروليكية رافعة قائمة

- الآثار البيئية الناجمة عن تعدين الفحم والحجر الجيري

- Macam Macam Peralatan Grinding And Sizing

- Components Of Crusher Plant

- U S Industrial Mills Milling Machines Vertical Horizontal

- Mill Stor Flour Mill

- Cone Crusher Kind Hp 2021

- Coal Tar Pitch Plants In Luxembourg

- Instruksi Manual Cone Crusher Pdf

- Grinding Steel Ball Exhibition

- Buy Mining Equipments Iran Mtm Crusher

- Belt Conveyor With Factory Price For Sale

- Stone Crushing Machine To Crush Limestone Marble Quartz

- Mill Cutters For Mwall

- Limestone Mining In Uganda

- Vinograda Drobilka Dlya Prodazhi Avstralii

- How Much Copper In Gas Hot Water Tank Worth