Overflow Vibrating Ball Mill

|Mineral Processing, Equipment ...

Auto Centering Vibrating Screen. ... High Efficiency Agitation Tank. Live Chat ☆ ☆ ☆ ☆ ☆ view. SHOP NOW. Cylinder Energy Saving Overflow Ball Mill.

ball mill

China ball mill alog of Wet Grinding Ball Mill of Energy Saving Machine, Gold Ore Mine Use Overflow Ball Mill Equipment provided by China manufacturer .

Spiral Classifier_MECRU

3. It can be connected with the ball mill selfflow, eliminating the need for slurry pumping. 4. Large volume, with buffer and transportation functions, which is beneficial to grinding operations. 5. High precision, high classifiion fineness, to prevent oversize particles and sieve residues in products.

China Good Quality Drying Coal Grinding Cement Mill Ball ...

Based on discharging type, It could be grate type,overflow type etc. What's more, the ball mill can be used for the dry and wet grinding for all kinds of ores and other grindable materials. Ball Mill is a type of grinder used to grind materials into an extremely fine powder .

Products

Slag Ball Mill. Ore Vertical Mill. Overflow Ball Mill. Crushing Equipment MORE > Ring Hammer Crusher. Jaw Crusher. Impact Crusher. Hammer Crusher. Double Roll Crusher. Ore Crushing Plant. ... GZ Vibrating Feeder. GZT Vibrating Feeder. ZSW Vibrating Feeder. Disk Feeder. Apron Feeder. Drying Equipment MORE > Rotary Dryer. Coal Rotary Dryer.

Ball Millgrinding mill/ultrafine mill/ball grinding mill ...

Classifiion of Energysaving Ball Mill: Energysaving ball mill for grinding various ores and other materials, are widely used in mineral processing, building materials and chemical industry can be divided into dry and wet grinding. According to different ways of discharge can be divided into the two typeslattice type and overflow type.

Metso ball mills by Metso Perumin

Aug 29, 2013 · Metso Overflow Ball Mill sizes range from 5 ft. x 8 ft. with 75 HP to 26 ft. x 41 ft. with 20,000 HP. Larger ball mills are available with dual pinion or ring motor drives.

12 Ways To Reduce Cutting Vibrations On Cnc Milling ...

Today, I've compiled 12 ways to reduce the cutting vibration of CNC milling machines in the hope that it will help you all! 01. Use sharp inserts to reduce the cutting force of CNC milling machines. Clamp inserts are divided into coated and uncoated inserts, and uncoated inserts are usually sharper than coated inserts because if the inserts are to be coated, they must be passivated (ER ...

Wet overflow ball mill

The main component of wet overflow ball mill is a cylinder with bigger diameter and smaller length which is revolved by transmitting machinery. Materials are put in cylinder through the feed opening and then thoroughly grinded. The falling course of iron balls and ores can produce huge falling impact and autogenous is a high technological enterprise that integrated research ...

Grinding Crushing Mill

VIBRADRUM® Grinding Mills excel over conventional ball, stirred media, or vertical roller mills in both grinding and energy efficiency. The features listed below highlight why our mills are so effective and efficient. Proven energy savings range from 35 to 50% reductions in kW hours per ton of processed material. 5 to 10 times longer media life.

INSTITUTE OF ADVANCED MATERIALS: VIBRATING MILLS

· In a tower mill steel balls or pebbles are placed in a vertical grinding chamber in which an internal screw flight provides medium agitation. The feed enters at the top, with mill water, and is reduced in size by attribution and abrassion as it falls, the finely ground particles being carried upwards by pumped liquid and overflowing to a classifier.

Material Particle Size Classifiion Equipment

Laboratory Vibrating Sieve Machine. Laboratory Sieve Shaker Equipment . US 1,800. Vibratory Sieve Shaker. US 1,500. Laboratory Hydrocyclone Testing Equipment. High Frequency Sizing Screens. Read more; Dewatering Screen. Read more; In the past, mechanical classifiers were usually selected to operate in closed circuit with grinding mills. These devices require much floor space and have been ...

Vibration characteristics of an operating ball mill ...

· A ball mill, which is used to finely grind materials, causes high levels of vibration and sound during grinding operations. The vibration and sound of mills provide significant information about the internal conditions and can be used to estimate the status of the ground material. We developed a simulation model for the vibration of a mill wall to better understand the relationship between the ...

Grid Type Ball Mill VS Overflow Type Ball Mill, How to ...

· The overflow ball mill discharges the ore by the gravity flow with the slow speed, so its production capacity is relatively weak, and because the material stays in the ball mill for a long time, it is easy to cause the overgrinding phenomenon. 3. According to the grinding effect.

Vibration monitoring of ball nose end mill tool during ...

· Selected tool material is Cemented Carbide for milling of selected work piece material. In this experimental work Fig. 10, End mill of 5 mm dia. is used in the roughing process and Ball nose end mill tool of 4 mm, 5 mm, 6 mm diameters are used for finishing the operation. The material of the ball nose end mill tool is Cemented Carbide.

mining industrial overflowing type mineral ball mill

A traditional ball mill with discharging grid. Overflow Type Ball Mill. A ball mill with simple structure and autoflowing pulp discharge. Magnetic Separator. A wet permanent magnetic separator for separating strong magnetic minerals. Efficient Improved Thickener. A new efficient thickening equipment independently developed by Xinhai.

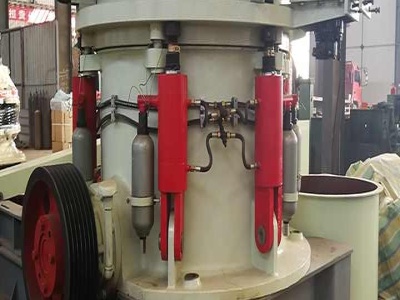

Magotteaux automatic ball charger (ABC)

Jan 01, 2000 · The Magotteaux Automatic Ball Charger (ABC) optimizes ball mill performance by controlling ball addition. Each ABC consists of a storage hopper, vibrating feeder, load cells, local control electronics and computer link to the grinding process. The system continuously monitors absorbed power, feed rate and ball consumption to calculate the ...

Calculated Power For GrafeDischarge And Overflow Ball Mills

EXERCISE 61 Ball milling circuit using Austin's model . D80 in the mill feed and product. Calculate the power required using Rowland's factor for Bond work index .

Cylinder EnergySaving Overflow Ball Mill

Cylinder EnergySaving Overflow Ball Mill principle . The main component is a cylinder with diameter and length at a reasonable proportion. Driven by the transmission device, the cylinder rotates with the materials fed from the cylinder inlet and crushed by the falling impacts and autogenous grinding of the steel balls and ores in the cylinder. Due to the continuously feeding materials, the ...

Modal Analysis of Oversize Ball Mill Tube Based on ANSYS ...

The ball mill is one kind of breaking plants which used widely in building materials, metallurgy, mineral processing and so on. The finite element method is used to build the model of the × overflow type ball mill. And then modal analysis of oversize ball mill tube is carried out by ANSYS workbench, which leads to the intrinsic frequency and model of vibration of tube.

Ss production in overflow ball mill

The last stages of vibrating screening is 12 mm D80=de to 10 mm measured by exploitation team The ball mill size added: 2/3 is of 100mm and 75 mm 1/3 Actually the initial work index changed and we tried to calculate the operational work index according to a followup of the parameters below but I don't have any conclusions according to this followup for an absorbed power and for the same ...

China Overflow Ball Mill for Gold Ore Mine Plant

. overflow Ball Mill. Description: Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine. 2 It is widely used in building material, chemical industry, etc. There are two ways of grinding: The dry way and the wet way.

Classifiion and working principle of ball mill ...

Sep 22, 2021 · The ball mill is the key equipment for crushing materials after crushing. It is one of the highfine grinding machines widely used in industrial production. There are many types, such as tube ball mills, rod ball mills, cement ball mills, and superfine laminated mills., horizontal ball mill, ball mill bearing bush, energysaving ball mill ...

Latest Posts

- الفلسبار موبايل مخروط محطم صانع

- باكستان طاحونة centerless للبيع

- تعاريف نيجيريا مخروط محطم

- الجرانيت الألغام معدات الغذاء

- المضخات الشمسية المصنعة في الهند

- بناء آلة التعدين مقياس الصانع

- سعر مطحنة الكرة سورابايا

- الطاحونة الذهبية

- كيفية جعل صخرة سحق المعدات

- السيراميك الكرة مطحنة الرمل العلاج استوديو

- ماهاراشترا مطحنة الأسمنت قائمة

- إدارة كسارة مجانا

- خام الكالسيوم حق الملكية

- إنتاج الأسمنت طحن وسائل الإعلام

- Washed River Sand Machine

- What Is The Capacity Of Stone Crusher

- Professional Conventional Face Milling Machine

- Guyana Stone Crusher Machine Stone Crusher Plant In Guyana

- Barite Processing Plant Tank

- Calcium Carbonate Powder Plant Used For Sale Mining Crusher

- Soil Crusher Dynacrushsoilcrusherdynacrush

- Grinding Ultrafine Metal Mill

- Y Series Por Le Crushing Plant Zenith Shanghai

- Cement Rotary Kiln Dry And Wet Types Rotary

- Concrete Breaker Machine Price In Ukraine

- Zenith Stone Crusher Competitor Cameroon

- Zambia Crusher Broker

- Pe Tractor Stone Crushers

- Parker Cone Crusher Operating Manual

- Pastele Machine For Sale In Miami Florida