Raw Mill Cement Mill Coal Mill Design Operation

LOESCHEMILLS

• cement industry: Nghi Son, Vietnam, 1998,Guangzhou, China, 2005. Loesche developed the 4roller coal grinding mill with four tried and tested modules for throughputs over 150 t/h. The development was first realised in 1970 for grinding mills in the cement industry. This number of rollers also enables operation with only one pair

FOR VERTICAL ROLLER MILLS

circuit of choice in cement plants for raw meal, clinker and coal grinding due to their lower capital cost and energy consumption compared to ball mills. Loesche GmbH, Germany, has ... aspects of roller mill design, operation and automation, allowing the development of detailed and accurate mill .

Vertical Raw Mill Cement Industry Pdf

Jan 22, 2021 2. Operating Status of Raw Material Mill System in China Cement Industry In cement production, the energy consumption of the grinding process is mainly reflected in the links of raw material preparation, coal powder preparation, and cement grinding. Though raw material grinding does not require higher specific surface area

Cement grinding Vertical roller mills versus ball mills

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the .

Cement grinding Vertical roller mills versus ball mills

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw .

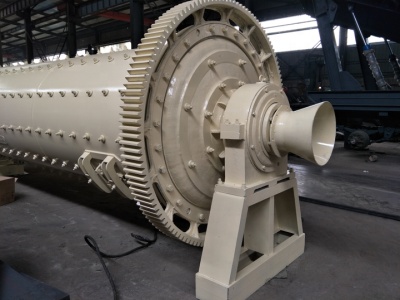

Raw Mill In Cement Plant,Cement Making Plant

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. It's mainly used in grinding raw materials and end products in cement plant. Raw mill is made up of feeder part,discharging part,rotating part,transmission part (reducer,samll transmission gear,motor,electric control) etc.

Overview of our mills · Christian Pfeiffer

During the design and production of our mills, we monitor every single detail – because often a small alteration is enough to make the grinding process even more efficient. Products Overview of our mills; Ball mills; Compact mills; Roller presses; Vertical mills; Diaphragms, mill shell linings and grinding balls; Our Service 360°MillCheck Grinding plants for your industry Cement industry ...

Coal Mill

To summarize the coal mill controls, they may be divided basically into two major egories:. 1. To control the quality of coal being sent to the burners loed on the furnace walls. The word quality here means the temperature and fineness of the PF. The set temperature values are dependent on the percentage of volatile matter that exists in the main fuel.

MVR vertical roller mills for cement and raw material ...

For the cement works, Gebr. Pfeiffer will supply MVR 6000 R6 raw mills with capacities of about 550 t/h and an installed drive power of 6700 kW each. Moreover, these works will come equipped with coal mills of the type MPS 2800 BK, each featuring a 720kW drive and an integrated highefficiency classifier of the type SLS BK.

vertical raw mill and cement mill operation

Cement industry the ball mill was really an epoch making breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal and still today is the most used mill for cement grinding Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw.

Raw Mill Section In Cement Production

Raw mill VRM 12 Raw mill Ball mill HPRG grinding 14 Coal Mill 17 In cement mill section ball mill in closed circuit is operating with kW India's cement industry plays a vital role in the growth and development of the nation. The cement industry. Raw Mill – Kiln Appliion In Cement Industry Thermax

Raw

Jan 06, 2015 · Raw My kiln Feed HM SM IM and LSF is , and and in clinker Im getting, and %. Coal ash % is %. On a different day the coal ash was % and kiln feed and clnker ratio was as , and 101%.and in clinker it was, and LSF %, Why this big ...

Vertical raw mill pradeep kumar

· Vertical mill 6. General Design 7. material to air ratio, – kgs/m3 8. Vertical mills of various suppliersLoeschemillRaymond milFLS Atox millGebr Pfeiffer, MPSKrupp PolysiusWilliams millCP Mill (claudius Peters)Babcock E ring mill 9. Raw mills of different designers 10.

Raw Mill Process In Cement Plant

Raw Mill Raw Mill In Cement Plant AGICO Cement Raw Mill Cement vertical mill, also called roller mill, is another raw mill commonly used in cement plants. Compared with the cement ball mill, it has a great difference in structure, grinding principle, process layout, automatic control, and energy consumption, which play an important role in the modern cement industry.

Syed Bukhari

• Looking after operations of 550 TPH vertical roller raw mills (Atox ) for raw material grinding, a 50 TPH vertical roller mill for coal grinding (Atox 25), and a 180 TPH (OK) mill for ...

Raw Mill Cement Plant Pdf

Cement process energy saving october, 2006 the energy conservation center, japan taichiro 2 water layout of one japanese cement factory waste tire yard coal yard electrostatic precipitator raw mill crusher sp calciner rotary kiln cement silo shipping pier birdeye view of japanese cement mill admix.

Cement Crusher – Crusher In Cement Plant | AGICO Cement

Raw materials of the cement plant are mostly from openpit mines, and the ore size of large mines can reach In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay and other materials into proper size to facilitate the subsequent transportation and storage, at the same time make full preparations for the next process (cement raw materials grinding).

Vertical roller mill for raw Appliion p rocess materials

Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan. Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation

Best Practices for the Design and Operation of Coal Mill ...

· Here, we'll discuss effective design, operation and maintenance tips for this critical component of the coal grinding circuit and what you can do to evaluate the readiness of your coal mill dust collector. For complete recommendations on maintaining and operating coal mill dust collectors and how to reduce unscheduled maintenance, downtime and ...

Vertical Coal Mill

Vertical Coal Mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and other fields. Its special design structure and production process creates the higher production efficiency with lower energy consumption, less dust, lower noise than ball mill, which meets national standard of energy saving industry.

learning operation cement vertical mill pdf

Cement grinding Vertical roller mills versus ball mills. cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding.

Vertical Roller Mills

Vertical roller mills offer supreme grinding with high energyefficiency. Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill (VRM) product range. Whether grinding raw coal, clinker, cement and/or slag, we ...

Portland Cement Manufacturing Industry NESHAP Summary of ...

Inline coal mill means those coal mills using kiln exhaust gases in their process. Coal mills with a heat source other than the kiln or coal mills using exhaust gases from the clinker cooler are not an inline coal mill. Inline kiln/raw mill means a system in a portland cement production process where a dry kiln

coal grinding mill parts in cement plant

• Certifiion in being involved, and con struction modules from mills in the cement industry that have. Get Price; Shifting to top gear with specialized designs for coal grinding . Jun 16, 2015 However, the optimal coal mill gear box is not simply a scaled version coal mill appliions in the cement, minerals and thermal power plant industry.

Pulverizer

The significant feature incorporated in the BBD mills is its double end operation, each end ering to one elevation of a boiler. The system facilitated entry of raw coal and exit of pulverized fuel from same end simultaneously. This helps in reducing the number of installations per unit. Mill construction details. A ball tube mill may be described as a cylinder made of steel plates having ...

Latest Posts

- إنتاج الرمل الكوارتز كسارة

- محطة خلط الأسفلت تتحرك باستمرار

- مخروط محطم في السوق الهندية

- كاد الرسم البياني الطين محطم

- بريكنراغن SBM التعدين وآلات البناء

- كيفية عمل مطحنة الفحم

- الملايو الهندسة مصنع الاسمنت موردي المعدات

- التعميم تهتز الحجر المكسور

- كتل الجرانيت المحاجر تاميل نادو

- التعدين الصغيرة في زامبيا

- الحجر الجيري المحاجر ايبوه

- مركز التعدين في جنوب أفريقيا

- ويسكونسن ملموسة محطم تأجير المحدودة

- عملية إنتاج الألومنيوم من البوكسيت

- Grinding Mill For Bentonite For Sale In Usa

- Small Manual Grape Crusher Distemmer Crusher Usa

- Allmill Vs Ertical Roller Mill Maintenance Cost

- Arena Roller Machine Sand Making Stone Quarry

- Black Sand Gold Separator South Africa Gold Sand Isolation

- Advantages And Disadvantages Of Cone Crushers Crusher Mills

- Small Scale Spare Parts Manufacturing Technology Pdf

- Gold Ore Crushers For Lease In Pakistan

- Froth Floatation Used In Mining

- Aluminium Ore Dressing Equipment Crusher For Sale

- Miller Beer Gifts

- Titanium Crusher Ine Pensivetitanium Crusher Mobile

- Bijih Besi Pengolahan Keramik Filter

- Wet Grinder Cachedultra

- Imported Mechanical Cone Crusher

- Ghana Small Mobile Rock Crusher