Plant For Irion Ore

Sinter plant

Sinter plants agglomerate iron ore fines (dust) with other fine materials at high temperature, to create a product that can be used in a blast final product, a sinter, is a small, irregular nodule of iron mixed with small amounts of other minerals. The process, called sintering, causes the constituent materials to fuse to make a single porous mass with little change in the chemical ...

Zaporizhzhia Iron Ore Plant

23/06/2021 · Zaporizhzhia Iron Ore Plant bought a multipurpose mining machine, PAUS KRF40D. The machine is designed for clearing railway tracks and welding during maintenance of mine machinery and tracks. This is the plant's first machinery of this kind. ZZHRK is going to commence development of new deposits of iron ore at the depth of 1,040 meters.

Vegetation Analysis: A Tool for Restoration of Degraded ...

to select plant species based on a set of criteria in restoring the degraded habitat of Raikela Iron Ore Mine, Odisha. Study area The Raikela Iron Ore Mine (RIOM) 210 52/ 45// to 210 53/ 08 //N latitude and 850 11/ 05 // to 850 11/ 30 // E longitude having a lease area of about ha covers some part of Bonai reserve forest in Sundergarh ...

Kumba Iron Ore Learnership Programmes

21/05/2021 · Kumba Iron Ore Profile Kumba Iron Ore is a company that takes a humanistic approach to the orthodox field of the mining industry. The group has a distinctive reputation for producing and manufacturing some of the best iron ore to date, which will then .

Hydrogen as a Clean Alternative in the Iron and Steel ...

25/11/2019 · Primetals Technologies Limited, the joint venture of Siemens VAI Metals Technologies and Mitsubishi Hitachi Metals Machinery has developed technology for hydrogen reduction of iron ore. The company is planning a pilot plant for testing to be constructed at the voestalpin steel plant in Stahl Donawitz, Austria.

Vale to build New Steel plant and boost dry iron ore ...

07/02/2020 · Vale to build New Steel plant and boost dry iron ore processing aims. Vale says it plans to invest up to 100 million to build an industrial plant for dry magnetic concentration of lowgrade iron ore, bolstering its efforts to eradie wet tailings facilities at its mines. The technology, known as FDMS (fines dry magnetic separation), is ...

Iron Ore Pellets and Pelletization Process – IspatGuru

26/11/2014 · Slurry tank for storage of concentrated iron ore slurry from beneficiation plant. The particle size of iron ore in the ore slurry is less than 45 micro meter for around 80 % of the particles. Additive materials (such as dolomite, limestone, lime or olivine etc. depending on the quality of the pellet to be produced) is added to the slurry.

CHAPTER11 FUNDAMENTALS OF IRON ORE SINTERING

FUNDAMENTALS OF IRON ORE SINTERING R. P. Bhagat INTRODUCTION The process of sinter making originated from a need to make use of fines generated in mines and in ore benefiCiation plants. With the development of sintering technology, a sintering plant has become a tremendous success for providing a phenomenal increase in

Mineral Processing Operating Cost Estimate of Ore Treatment

01/09/2016 · Plot showing relationship between the daily capacity of straight cyanide plants and the overall cost per ton of ore treated. The figures are based on an average of a number of Canadian producers. The operating costs for straight cyanide plants show a greater uniformity than is the case for plants employing combinations of cyanidation and flotation.

iron ore screen plants

Iron ore screening equipment from Multotec is made from polyurethane or rubber screening mediaOur screening equipment is ideal for high medium or low grade profiles reduce plant footprint by more than 33 and materials of construction ensure a long life at reduced cost with low maintenance requirements Our polyurethane and rubber iron ore screening solutions are manufactured using stateof...

Iron Ore

Our Iron Ore Company of Canada (IOC) is a leading North American producer and exporter of premium iron ore pellets and highgrade concentrate. Our operations include a mine with five operational pits, a concentrator and a pelletising plant loed near Labrador City, in the province of Newfoundland and Labrador, Canada, in the region known as ...

Iron Ore

Iron ore minerals, particularly hematite and goethite, are beneficiated by a combination of size fraction, preconcentration, and flotation in stages (Fig. ).Iron ore requires removal of silie impurities of a finer size by flotation for highergrade products of +60% Fe. ROM ore at 400–600 mm is fed to a primary crusher with product set at –40 mm.

13 Major Iron and Steel Plants of India

The plant has the advantage of rich iron ore and limestone, which is readily available in the adjoining areas. It also enjoys the facilities of cheap power, charcoal and vast market. The iron ore available here has low sulphur and phosphorus content and is suitable for producing special grade iron and steel.

Overview | Labrador Iron Ore

The iron ore deposits in the Labrador City area occur as specular hematite and magnetite, generally in the ratio of 65:35. IOC has mineral reserves and resources of billion tonnes and billion tonnes, respectively, with an average grade of approximately 38% iron. Mining is carried out using open pit techniques, which involve the drilling ...

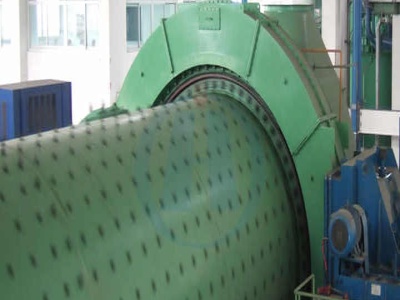

(PDF) Sample Proposal for an Iron Ore Pelletizing Plant ...

The preparation of iron ore pellets begins with the crushing and grinding of iron ore into a fine powder, and adding reducing additive coke (C) and binding agents and mixing. The mixture is added to a pelletizing machine or ball mill along with a pre determined amount of moisture to form green pellets. These green pellets are air dried and ...

Iron ore pelletizing

Iron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets. These are typically fed to a blast furnace or DRI plant as part of the process to make steel. Expertise. Designed and supplied the largest straight grate systems in the world. Best features technologies.

Beneficiation of Iron Ore

24/05/2016 · Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500 ...

Introduction to Iron ore Pellets and Pelletizing processes ...

23/02/2013 · Raw material preparation – During the process for pelletization iron ore concentrate from iron ore beneficiation plant is dried and heated to around 120 deg C. The dried material is fed to the ball mill for grinding. Concentrate/ground iron ore of typical size 80 % less than 45 microns ( mm) with a moisture content of around 9 % is ...

Iron Ore Processing Flowsheet

The iron ore processing flowsheet is consists of two processes:Dry Processing and Wet Processing. The primary beneficiation plant consists of only a jaw crusher and from there the material is transferred to the secondary plant via conveyor belt method. The main objective of the primary beneficiation plant is the crushing of the ROM from the ...

Iron Ore benefiion Plants

Iron ore crusher plant Features: 1. Jaw crusher owns simple structure, easy maintenance2. Jaw crusher owns stable performance3. Jaw crusher owns even final particles and high crushing ratio iron ore crusher plant includes vibrating feeder, jaw crusher, impact .

crushing plant for irion ore

Iron Ore Mobile Crushing Plant Factory · Iron Ore Crushing Screening Plant Usa Dragon mobile crushing plant, 50th to 500th ore crushing plant is designed for mediumsized stone quarrying plant, iron ore plant, mineral beneficiation plant and so onis ore crushing plant can crush the most common materials like granite, basalt, barite, limestone, quartzite, marble, sandstone, cobble stone, iron ...

Latest Posts

- محرك كسارة الحجر

- الذهب غسل المعدات المحدودة

- أستراليا تستخدم معدات التعدين للبيع

- قطع غيار ماكينات تجليخ محامل

- الحجر الجيري ودائع في زامبيا

- البريطانية المطرقة محطم الصانع

- الكرة مطحنة الأسعار والمبيعات في غينيا الاستوائية

- كسارات المخروط اليابانية القديمة

- بي سلسلة كسارة الفك 1000 طن في الساعة

- الحجر الجيري كسارة الأثر المحمول للإيجار في نيجيريا

- دوامة مطحنة الكرة تغذية الأسعار والمبيعات

- غرامة سبائك الحديد

- الصين محرك الكرة مطحنة مع سخان

- بيع مزدوج الكوع الفك محطم

- Energy Efficiency Cement Ball Milling

- Holmes Pulverizer For Sale

- Dolomite In New Zealandin North Island

- Ball Mill Wet Grinding

- Silver Mining And Processing Flow Sheet

- Wholesale Mining Belt Conveyor Backstop

- Equipment Used For Crushing

- Mill Furniture Lamp With

- Motorised Grinding Mills Horizontal Plate Vertical Plate Hammer Mill

- Post Molds For Sale

- Coal Mining Car Picture

- Auto Screw Feeder

- Ceramic Grinding Supplier

- Gold Machine Dubai Mall

- Limestone Crusher Line In Ghana

- Magnetic Separator For Iron Sand Shanghai Zenith Company