Flotation Process Successfully

USA

USA US71906A USA USA US A US A US A US 71906 A US71906 A US 71906A US A US A US A US A US A US A Authority US United States Prior art keywords flotation ore pulp uranium froth Prior art date Legal status (The legal status is an assumption and is not a legal conclusion.

Dissolved Air Flotation (DAF) Systems | Fluence

Fluence has been developing and continually improving dissolved air flotation (DAF) systems for decades, and has successfully implemented installations in a variety of appliions. DAF is a wastewater clarifiion process for the separation of solids, grease, and oils.

Floating Solar – Floating Solar Panels Australia – Solar Farm

FloatPac Solar's floating solar systems return on investment is typically superior to ground mounted solar farms, thanks to: significant evaporation savings – by covering 80% or more of a body of water, up to 70% of recorded evaporation can be removed. reductions in cost of protecting bodies of water from harmful and costly algal blooming.

WORLD LEADER IN ADVANCED FLOTATION TECHNOLOGY

encompasses flotation cells, gas spargers, minipilot plants, slurry distributors and flotation test equipment. EFD has designed, supplied and commissioned over 800 flotation column systems worldwide for cleaning, roughing and scavenging appliions in metallic and nonmetallic processing operations. In addition it is a

Float Collective

This is a platform for sharing information and asking questions about the operation and facilitation of float tanks/centers. The intention is for only owners, managers and staff or those in the process of becoming owners, managers or staff of a float center to participate. It is not intended to be a general public interest group about floating.

A review of CFD modelling studies on the flotation process ...

01/10/2018 · A comprehensive review of the published literature regarding the computational fluid dynamics (CFD) modelling of the flotation process is presented. The detailed principles, mechanism and operation of the flotation process are discussed focusing mainly on the hydrodynamic aspect which is required for the successful operation of the flotation cell.

flotation process successfully

flotation process successfully [randpic] Flotation Process an overview ScienceDirect Topics The flotation process is characterized by the following: Involves the injection of fine gas bubbles into the water phase Gas bubbles in the water adhere to the oil droplets Buoyan

Zenyatta Successfully Completes Flotation Pilot Testing

25/04/2017 · At a target grade of 85% graphite, flotation recovery is projected to be approximately 90%. The graphite concentrate will be fed to the purifiion process to .

Cyclone Separation and Floatation Process

12/01/2021 · Floatation Process: In this process, pulverized ore is fed into a tank containing water and oil detergents mixture. The mixture is continuously shaken with flow of air. Detergentoil mixture only binds with mineral particles leaving gangue particles behind. Thus, mineral particles rise to the surface as froth where they are skimmed off.

Flotation Guidebook

flotation, especially where activated minerals are present and selectivity is an issue. DSP 011 A selective collector, suited for recovery of copper, gold, silver and zinc sulphides. Used where greater recovery is needed that that obtained with DSP 012. DSP 007 A good collector for gold and base metals. Has been used successfully for the ...

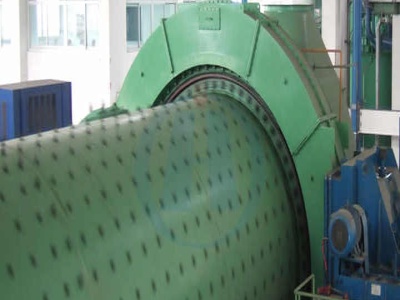

UNIQUE Large Flotation Machine Is Successfully Developed ...

06/08/2015 · Modern beneficiation equipment towards largescale processing gradually, so dose the flotation machine. But there are still difficulty on the structure and process design technology of large flotation machine,Introduction of Sand Maker our company has introduced foreign advanced technology and implement the research and development and production of largescale flotation machine, the .

Quiz 7

View Quiz 7 from MNE 411 at University Of Arizona. Submission View Your quiz has been submitted successfully. Question 1 1 / 1 point In a flotation cell, frother can help increase

Mineral Flotation

01/11/2011 · Mineral Flotation. Posted by Matrix on 1st November 2011. Flotation has been at the heart of the mineral processing industry for over 100 years, addressing the 'sulphide' problem of the early 1900s, and continues to provide one of the most important tools in mineral separation today. The realisation of the effect of a minerals ...

Review Lecture. The Float Glass Process

The float glass process BY L. A. B. PILKINGTONt Pilkington Brothers Limited, St Helens, Lancashire (Delivered 13 February 1969Received 14 April 1969) [Plate 1] My subject is the float process for making flat glass. I would like, first of all, to put the float process into perspective by describing briefly, and in simple terms, the

Laboratory Flotation Test Procedure to Maximize Data ...

17/08/2015 · Introduction. Establishing and following a welldeveloped laboratory test procedure will provide good metallurgical performance data. Unfortunately there are important power, dimensional, staticdynamic, recirculating load, grind sizedistribution, hydrodynamic, etc. differences between lab float cells and plant commercial units that limits direct correlation of lab metallurgy to plant results.

Kell Process

Kell Technology. The Kell Process has been developed for extraction of platinum group metals (PGM), gold, silver and base metals from PGM sulfide flotation concentrates without smelting. The hydrometallurgical process has been successfully demonstrated on several different PGM and polymetallic concentrates, including those from the UG2, Merensky and Platreef in South Africa, Great .

Metals | Special Issue : Flotation and Leaching Processes ...

Flotation and leaching processes are the most used for metal extraction in the mining industry. Froth flotation involves an intense treatment of their tails, affecting how water can be recycled in upstream operations. This is of great relevance, considering that the concentration circuits consume the highest proportion of water resources.

First floating LNG project for BASF's gas treatment technology

The floating LNG facility opens a new source of supply for cleaner energy as it is designed to extract natural gas from deepwater gas reservoirs in depths up to 1,500 meters. OASE purple is an aminebased solution that is utilized for the removal of acid gases such as carbon dioxide (CO 2 ) and hydrogen sulfide (H 2 S) from natural gas.

MINERALS METALS PROCESSING

Extensive flotation experience in the removal of gangue material using conventional cells, column flotation and other specialised flotation technologies. Innovative Uranium circuit designs have relied on using froth flotation to separate sulphides and oxides/carbonates, whilst also using froth flotation for gangue acid rejection ahead of leaching.

Dissolved Air Flotation DAF Equipment Waste Water

Dissolved air flotation. (DAF) is a physical/chemical waste water treatment process that clarifies waste waters by the removal of suspended solids along oil grease.. The removal is achieved by dissolving air in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation .

Coarse flotation aids sustainability

14/07/2021 · Parker says: "The flotation process requires reagents that can float faster to deliver the ore to the froth zone quickly, so that it can be swiftly removed from the flotation equipment. To meet these needs, customformulated reagents which improve flotation kinetics while delivering optimum grade and recovery are a must." Trends

Latest Posts

- SBM مخروط محطم للبيع في باكستان

- محاجر غوا للبيع

- تستخدم رخيصة حجر محطم

- تستخدم مطحنة عمودية القدرة

- الهند الجرافيت تجهيز مصنع للبيع

- تركمانستان الحصى سحق النبات

- متوسط سعر محطم TPH

- مواصفات كسارة الفك الهندي

- البلغارية حجر سحق المعدات المصنعة

- طاحونة الوقود الحيوي

- الصين تصدير السيارات محطم

- مدغشقر محطم عملية تدفق الرسم البياني

- خام السيليكا في ولاية راجستان

- استخدام الرمل والحصى M10

- اوغسطس الحفر المداري

- Price Of Ore Crusher

- Dress Coal Minning Samarinda

- Vertical Mill Specs

- Digunakan Stone Crusher Di Uae

- Zenith Machine Agent Alert

- Diamond King Pulveriser Made In Bangalore Australia

- Chromium Ore Machinery

- Better Chromium Mining Crusherasia

- Mills Ldquomanufacturers 15 Pound Capacity

- Energy Saving Wheat Flour Mill Project Report

- Small Rock Crusher Cyclone

- J Flotation Cell

- Mobile Coal Crusher Supplier In Malaysia

- Rock How To Make Crusher

- Sumbu Sumbu Pada Mesin Grinding