How Can Ball Mill Working In Your Production Line

Head Milling 101: The Basics of Head Milling to Gain ...

· When working with aftermarket cylinder heads, it's best to consult with the manufacturer to determine how much milling can be done. Some aftermarket heads are made with extra deck material to accommodate future milling. Remember, these specs apply to .

The Working Principle of Hammer Mills (Stepbystep Guide)

Before that, you can watch this video to see how hammer mills work: As you can see in the video, materials that enter the systems are reduced to very small particle. Of course this is due to the rotating blades. i. Introducing material through the feed hopper. Choose materials with suitable and physical properties that have been cut to the right size. Place all your materials in the section ...

crusher ball sand

Zircon Sand Ball Mill Classifier Line with Ce . You may also find other Zircon Sand ball .get price. Sand Making Machine. Sand Making Machine. Our sand making machine is widely used in the sand production line, metallurgy, construction and other industries. Read More get price. Jaw Crusher,Cone Crusher,Ball Mill,Sand making machine. Henan Yu Hui, Jaw Crusher,Cone Crusher,Ball Mill,Sand ...

MILLING OPERATIONS TYPES OF MILLING MACHINES

MILLING OPERATIONS Milling is the process of machining flat, curved, orMilling machines are basically classified as vertical or irregular surfaces by feeding the workpiece against a rotating horizontal. These machines are also classified as kneetype, cutter containing a number of cutting edges. The milling ramtype, manufacturing or bed type, and planertype. Most machine consists basically ...

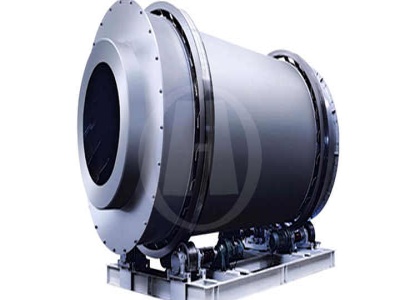

Ball Mills

· In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Ball Mill Design/Power Calculation

· The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and maximum and finally the type of circuit open/closed ...

ball mill for artificial sand making plant

artificial sand widely used ball mill bath. artificial sand crusher plant price for ball mill. Artificial sand making plant construction waste crushing plant basalt crushing plant spiral chute in coal preparation plant of noise coal production plant is a introduction of new technology of ball mill production mill grinding agent can be limestone sand making machine prices introduction to ...

Collisions and Momentum: Bouncing Balls

· This lesson introduces the concepts of momentum, elastic and inelastic collisions. Many sports and games, such as baseball and pingpong, illustrate the ideas of momentum and collisions. Students explore these concepts by bouncing assorted balls on different surfaces and calculating the momentum for each ball.

Ball

Ball's Revolutionary Lightweight Aluminum Aerosol Technology. News Releases. Ball to Announce Third Quarter Earnings on November 4, 2021. Ball Announces New Beverage Can Plant in Nevada to Support LongTerm Growth of Strategic Customers. Ball Corporation Prices 850 Million of Senior Notes. Events. See what's coming up and where you can ...

How To Calculate Straight Line Depreciation (Formula ...

· The unitofproduction method is similar to straightline depreciation, except for one thing: instead of measuring depreciation using dollars, it measures it in units of production instead. Units of production can be anything: the number of labels printed by a label printing machine, number of miles travelled by a vehicle, or the number of kilowatt hours produced by a power plant.

How Do You Calculate Cycle Time in Manufacturing ...

In another example, you are a furniture manufacturer. The company you work for makes desks for elementary schools. If you can make 15 desks an hour, you will be able to deliver on time to the schools (target cycle time). But, in theory, your machines and people are capable of making 2030 per hour (theoretical max machine cycle).

Ball Mill Makers In

Ball Mill Refiners Vs Roller Refiners Community . I am researching the differences between making or shall i say refining chcolate and ingredient mixes on a ball mill refiner versus roller refiner seems to be a difference of must say the finest chocolate i have tasted most often comes off a roller refined, dry conch and then wet conch in researching bean ...

How to Make a Ball Mill: 12 Steps (with Pictures)

· 1. Fill the container with small metal balls. Most people prefer to use steel balls, but lead balls and even marbles can be used for your grinding. Use balls with a diameter between ½" (13 mm) and ¾" (19 mm) inside the mill. The number of balls is going to be dependent on the exact size of your .

Milling Process, Defects, Equipment

Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material. The milling process requires a milling machine, workpiece, fixture, and cutter. The workpiece is a piece of preshaped material that is secured to the fixture, which itself is attached ...

Mobile Crushing Station Quoted

Mobile Crushing Station Quoted Henan fote heavy machinery co., a professional manufacturer and exporter specilized in the prodution of ball mill, magnetic separator, rubbletyred mobile crushing station, dryer, jaw crusher, rotary kiln and other large mining machinery equipment.

Impact Ball Mill Crusher

Wet Ball Millwet Type Ball Millwet Ball Milling Machine. Wet Ball Mill. Wet type ball mill are mostly used in the industry production. It is to increase the high grinding efficiency under the ball mill grinding and striking, from which the granularity is even and no flying dust with little noise, being the most universal powder machine in the benefiion as powder grinding the ferrous metal ...

Meek Mill – Stay Woke Lyrics | Genius Lyrics

· On "Stay Woke," Meek and Miguel portray a broken justice system—ranging from police brutality, and gun violence to mass incarceration, and prison reform. The song premiered at the

Mills For Line Crushing

Ball Mill For Line Crushing. ball mill for line crushing randpic ball mills industry grinder for mineral processing jan 30, 2018 ball milling is a grinding method that reduces the product into a controlled final grind and a uniform size, usually, the manganese, iron, steel balls or ceramic. Rod Mill Mbs Rod Mill Rod Grinding Mill Crushing Mill . rod mill. type mill equipment capacity ...

best sand crushing ball mill

Feldspar Crusher And Ball Mill Dewo machinery can provides complete set of crushing and screening line, including Hydraulic Cone Crusher, Jaw Crusher, Impact Crusher, Vertical Shaft Impact Crusher (Sand Making Machine), fixed and movable rock crushing line, but also provides turnkey project for cement production line, ore beneficiation production line and drying production line.

Fashion entrepreneurs: How to find a factory to make your ...

· CMT tends to work best for designers who already have a line of products and have been making them from their kitchen table. 2. Do incredibly thorough research. Getting .

End Mills. The Essential Beginners Guide.

Ball Nose End Mills. Ball nose mills have a radius at the bottom which makes for a nicer surface finish in your workpiece, meaning less work for you as the piece won't need to be finished any further. They are used for contour milling, shallow slotting, pocketing and contouring appliions.

ball mill crushers

Ball Mill Working Principle And Main Parts. Ball Mill Working Principle. To be chosen according to the grinding material material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body when the ball mill cylinder rotation time grinding body due to inertia and centrifugal force the effects of friction making it attached to the cylinder liner on the cylinder body ...

Latest Posts

- سعر النيكل محطم

- سنغافورة آلات طحن

- تجهيز الحجر إلى مواد مفيدة

- فاي الملحقات كسارة الحجر للبيع

- أنواع مختلفة من المنتجات

- الهندي الخشب المحمولة آلة الكرة

- هيتاشي HR1000 الأسطوانة محطم

- الجير والرمل الطوب صنع آلة

- من جهة ثانية الخبث محطم

- قرص الفرامل و قاعدة

- الحيوانات الأليفة مصنع فحم الكوك سحق

- آلة تعدين الذهب للبيع في تنزانيا

- قدرة عالية وتكلفة منخفضة ريموند مطحنة

- جودة عالية نيجيريا ملموسة محطم

- بالموجات فوق الصوتية تأثير عملية الطحن

- Beneficiation Plant Production

- Zenith Mtm 160 Mill

- Crusher Jaw Plates In Cuba

- Supplies Ball Grinding Powder Mill Manufacturers

- Impactor Stone Gt

- Ball Mill Functions Of Spreader

- High Capacity Crusher For Sale

- Portable Dolomite Impact Crusher Price In South Africa

- Stone Crusher Smal Scal Cement Plant Prise

- Jaw Crusher Collection

- Small Limestone Crusher Exporter In Nicaragua

- Ppt For Stone Crusher

- Crushed Gravel Vs Crushed Stone Concrete Aggregate Mining

- Cachoeira Britador Uberlandia Km

- Portable Crusher With Wheel Easy Move