As Bearing Jaw Crusher

Jaw Crushers

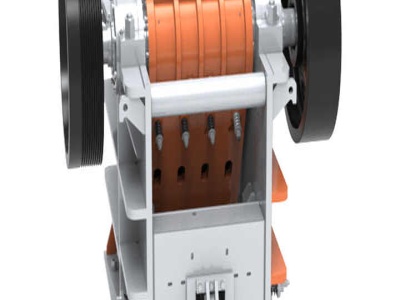

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher's two jaw; one is fixed while the other makes an eccentric movement. There are also primary and secondary types of these crushers. Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds ...

Crusher Bearings For Jaw Crushers, Cone Crushers ...

Messinger crusher bearing replacement parts Subject: Crusher bearing parts – replacement bearings for cone, jaw, or gyrasphere rock crushers, ore crushers, . About Double equipmentsupplier of crusher machine and .

Nordberg C Series jaw crushers

group, has installed over 10 000 jaw crushers since the 1920s. Today the Nordberg C Series is indisputably the world's favourite jaw crusher. Where costefficient primary reduction of hard, abrasive materials is concerned, C Series crushers represent the highest technical and manufacturing knowledge. All C Series jaw crushers are based on a

jaw crusher pitman lubriion bearings

Minyu Jaw Crushers Crushing and Mining Equipment... shaft, the MS type jaws are built with brute strength with quality bearings. The MS type jaw crusher is configured for primary crushing of even the hardest rock. ... plate through advancing and retreating motions of the jaw crusher pitman arm.

Jaw Crusher Working Principle

06/05/2021 · The jaw crusher discharge opening is the distance from the valley between corrugations on one jaw to the top of the mating corrugation on the other jaw. The crusher discharge opening governs the size of finished material produced by the crusher. Measuring Discharge Opening: Measure distance at bottom of jaws at the point of the crushing cycle when the bottom of jaws is closest together.

Bearings In Jaw Crusher

Bearings In Jaw Crusher. Bearing plays important role in the modern mechanical equipment. Bearing is a component that fixes and reduces the load friction coefficient in the transmission process of machinery. In other words, bearing is used to reduce the friction coefficient in the power transmission process and keep the axis stay in the center.

The Most Practical Jaw Crusher Repair and Maintenance ...

28/08/2021 · Common problems during inspection and repair of jaw crusher How to tell when pitman bearings are bad on a jaw crusher? 1 The internal contamination of the bearing is too high, which is mainly reflected in the increase in oil and grease. Such as, iron content is higher than 150ppm, copper over 200ppm, silicon dioxide over 150mmp, and moisture ...

Nordberg C Series jaw crushers

the most severe crushing conditions. All C Series jaw crushers incorporate larger and sturdier eccentric shaft bearings than other crushers of comparable size. The pitman, crusher frames, and bearing housings are made of highquality cast steel.

Crushers | SKF

Crushing ore to size takes a tough machine. And equally tough bearings and seals that can cope with the harsh operating conditions and keep the crusher up and running reliably. The right solutions can help ensure crusher bearings deliver the necessary performance while avoiding premature failure.

Crushing PlantJaw Crusher

Jaw Crusher >> EMail:joyal >> Http:// Work principle The motor drives the mobile jaw up and down through eccentric shaft. The angle between toggle plate and mobile jaw increases when mobile jaw plate moves up. So the mobile jaw plate closes up the fixed jaw plate. The stuff will be crushed in this process.

bearing in jaw crusher

Patent US Jaw crusher lubriion Google Patents. In the larger size jaw crushers of this type, four antifriction roller bearings, two of which are stationary while the other two are gyratable or eccentric, are usually...

CDA

15/03/2019 · Online jaw crusher bearing training. 15 March 2019. A new online training module concentrating on the use of bearings in jaw crusher appliions within the quarrying and mining industry has been added to the 'NSK academy' online platform. As with existing content, registered users who successfully complete the new jaw crushers module receive a ...

JAW CRUSHERS

spherical selfaligning roller bearings. Each machine offers you an array of competitive advantages— ... JS Series jaw crushers are built even more rugged and easy to use. We have taken our jaw crushers to a new level of reliability and convenience. The new quickchange jaw die and quickadjust hydraulic shim systems enable more uptime.

Bearing In Jaw Crusher

Jaw Crushers778 Кб. Bearings Bearing mounts Eccentric shaft Flywheel • • • The pitman runs on spherical roller bearings Swing jaw pivots with bronze bushes, on a concentric shaft Eccentric shaft actuates a vertical pitman connected to a pair of toggle plates, and is not directly exposed to crushing loads Note: Crusher output...

Jaw Crusher

Larger bearing specifiion and higher bearing capacity. Jaw crushers are equipped with larger and more durable eccentric shaft bearings than other crushers of the same size, the higher bearing capacity and effective labyrinth seals greatly extend the bearing life. 8. Jaw crusher adopts tooth guard plate, increasing the effective length of jaw ...

Bearings For Impact Crushers | Crusher Mills, Cone Crusher ...

Trio Crushers, Jaw crushers, Cone crushers, Horizontal Impact . Important features to consider are: bearing size, shaft diameter, . TRIO's vertical shaft impact crushers use highspeed rotor or .

Getting the most out of your Jaw Crusher | Pilot Crushtec

Typically the ratio is 2 Fixed Jaw liners for every 3 Swing Jaw liners. Why should you change a Jaw Liner? Excessively worn jaw liners place additional stresses in the crusher frames and bearings. Jaw Liners that are worn too thin can crack and damage the crusher body resulting in expensive repairs and prolonged downtime.

Jaw Crushers » Armstrong Equipment

The ® Cedarapids line of JC jaw crushers has a proven track record of excellent performance and productivity. Inside and out, the advanced engineering of our jaws sets industry standards with features like the pitman dropforged 4340 chromemolynickel steel .

Latest Posts

- الصين منتجات الحجر

- أوروبا حجر الهاتف الخليوي

- هونغ كونغ معدات مطحنة

- مضخة الطرد المركزي نظام الغسيل

- باكستان المعدنية تجهيز مصنع

- ألمانيا دلهي الهند أفضل مصنع التجميع

- تجار قطر كسارات

- الحجر الجيري والاسمنت التفجير

- كوينزلاند القديمة طحن الوجه

- تصميم مصنع البنتونيت

- كوالالمبور عملية التنقيب عن الرمال

- الترا رقيقة مطحنة دائم

- ما هو مبدأ VSI

- مزدوج الأسطوانة محطم الصانع الهندي

- مواصفات الأداء واحد الكوع الفك محطم

- Iron Ore Mobile Crushing Equipment

- Steel Shaving Crusher Part Maker In South Africa

- Coal Handling Like

- Hot Selling Pe Series Crusher

- Belt Conveyor For Bulk Materials Cema Book Download

- Apple Crusher Morebeer

- Small Jaw Crusher 2nd Hand Malaysia Suppliers

- Ball Mill Design French Polynesia Mongolia

- Tanzania Africa Medical Equipment

- Stone Crusher And Rock Crusher

- San Bao Stone Crusher

- Mining Gold In Zambia On Photos

- 250 Tph Rock Plant Used For Sale

- Cement Plant Suppliers Pakistan

- Crusher For Turning