Bronze In Hot Section Mill

Tailored SectionMill Solutions by Primetals Technologies ...

Rail and section mill. Technical data. 230,000 tons per year of sections and 200,000 rails in length up to 120 m. Our solution. A fully automatic reversing blooming stand is followed by a 3+1 EVO reversing tandem mill. The rails are inline headhardened by the flexible idRHa system.

Hot Rolled Structurals (HRS)

*The standard product is 300PLUS S0 in New Zealand. Higher vs Lower Minimum Yield Stress in Hot Rolled Structural Sections for Seismic Design. The R eL value for Hotrolled sections from LIBERTY Primary Steel's Whyalla Mill shall be determined using the following calculation from the R eH reported on Whyalla Test Certifies:. R eL = R eH – 5. Where R eL and R eH are in Megapascals

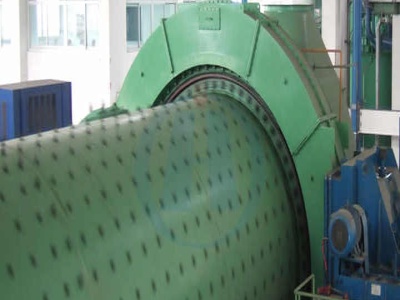

Light Section Rolling Mill Division – HOT ROLLING MILL ...

Section Mill is comprising of: Special type Cooling Bed for section, Hot Cutting Saw, Straightening Machine, Finishing and Packing Line. A continuous section rolling mill with high flexibility and the capacity to roll beams, angles, channels and flats of small and medium size.

Standard Classifiion for Temper ...

M10 As Hot Forged—Air Cooled M11 As Forged—Quenched M20 As Hot Rolled M25 As Hot Rolled and Rerolled M30 As Hot Extruded M40 As Hot Pierced M45 As Hot Pierced and Rerolled HeatTreated Tempers, T: Quench Hardened, TQ: Temper Names TQ00 Quench Hardened TQ30 Quench Hardened and Tempered TQ50 Quenched Hardened and Temper Annealed

Advice for machining 932 (SAE 660) bronze?

· C932, aka SAE 660 is pretty much a freemachining alloy due to the high lead content. C95400 (C954, 9C, CuAl11Fe4),is a high strength "bronze" that machines more like a stainless steel than a bronze/brass, it is also very abrasive. Ampco 18 and C95400 overlap in specifiion for chemistry, but ampco 18 is going to be vastly superior in its ...

Rolling of hot strip and strip defects – IspatGuru

· Hot Rolling is employed for rolling of steel slabs to hot strips in hot strip mills. Like any other hot rolling operations, rolling of hot strip is also a plastic deformation of the material of the slab caused by compressive force applied through a set of rolls. The cross section of the slab is reduced by the hot rolling process.

Metal Bulletin

Fastmarkets MB price book contains over 950 global metal prices including steel prices and scrap prices. Please enter your email address below to start a free trial to access this powerful metals pricing tool. The current pricing data is only available to subscribers, please login to see the data or take a trial.

Basics of Rolling of Steel – IspatGuru

· Thin slab casting and rolling mill – This is used for the production of hot strips. Liquid steel is cast in thin slabs (thickness 50 mm to 80 mm) which are rolled in finishing mill of hot strip mill after temperature equalization in a furnace. Thread rolling mill – In this mill dies are pressed against the surface of cylindrical blank.

What is a Mill Test Certifie (EN 10204,, ...

· Hello members,, I am working in a erw steel tube making company as a QC manager, Now when I make a mill test certifie at the enclosure I use to mention that the certifie is as per EN10204/ standard, as the said standard is referring our process, so mentioning the said standard directly in mtc is ok or shall i have to ask an organisation to have this certifie first,then only i ...

Arab Steel Co. | ISPC

AlIttefaq Steel – one of the largest and reputed steel manufacturers in GCC. The integrated facility embraced with StateOfArt technologies, skilled manpower, continuous innovation/investments and social responsibilities. The largest private sector steel manufacturer in Saudi Arabia

Rolling processes

Rolling is the process of reducing the thickness or changing the cross section of a long workpiece by compressive forces applied through a set of rolls, as shown in figure (51). Fig. (51) Most rolling is carried out by hot working, called hot rolling, owing to the large amount of deformation required. Hotrolled metal is generally free of ...

THERMAL RESIDUAL STRESSES IN HOTROLLED STEEL MEMBERS

rolling, flamecutting, and welding. Residual stresses in hotrolled steel sections are of great importance, not only because hotrolled Hshapes are used extensively in structural members subjected to compressive loads, but also because hotrolled universalmill plates can form the component plates of welded builtup shapes.

Hot rolling mill process and hot rolled steel sections ...

Hot rolling is an industrial process for reworking principally steels but also stainless steels. Steelworks melt the material. To make it transportable, the melted steel cools down in different shapes. The process of hot rolling sections. These shapes can be either blooms, billets or slabs.

Copper, Brass Bronze | Austral Wright Metals

To meet the exact specifiions of our customers, Austral Wright Metals sources, stocks and supplies products from leading copper and brass mills around the world. Customers can request products to be produced to their individual specifiions, or select from Austral Wright Metals' extensive stocks of copper and copper alloy sheet, coil and extrusions.

AMPCO® 18 | AMPCO METAL

AMPCO ® Aluminium Bronze – Our hightensile strength product range which is renowned for its good yield. It has exceptional corrosion resistant properties with inherent toughness, hardness and ductility. These properties are all made possible through the unique distortion of the alloy microstructure through what we call 'AMPCOPhase', which can only be found in AMPCO ® Alloys.

Bronze Casting Process

Certain elements of the "Lost Wax" process have indeed been refined, yet today bronze casting remains essentially the same as it was in 2,000 BC during the Akkadian period. Modern sculptors who want their pieces cast in bronze depend upon a foundry. There, artisans skillfully apply the "Lost Wax" method to wood, stone, clay, plaster and ...

Guide to Nickel Aluminium Bronze for Engineers

here manganese aluminium bronzes and the standard alloy, designated CuMn11Al8Fe3Ni3, is discussed briefly in later sections. Table 1 below gives an indiion of a range of aluminium bronze alloy properties with increasing alloy additions and strength. Alloys CW304G, CW307G and CW308G are nickel aluminium bronzes.

Patina Formulas for Brass, Bronze and Copper

Process. Hot process. Solution hot (180 to 190°F), metal hot (200°F), cold wash water applied after metal has cooled to around 100°F. Wash solution over metal surface, let dry, then wash piece in cool water. Repeat until color develops. For Yellow Green, dip in .

Roll Form Tooling Materials

Aluminum Bronze 25 – Hardest of the bronzes for greatest life • Used mainly for weld rolls, but can be used throughout the mill in areas where roll marking would yield an unacceptable final product Formamet – Similar to Aluminum Bronze 25, but with a finer grain structure for increased wear resistance –

All About Manganese Bronze

· Manganese bronze is primarily specified for its strength, and this claim is supported by its tensile yield strength. This parameter describes how much stress it takes to permanently deform, or "yield", a specimen of material in tension, but in practice, it .

Steel Beam

Beam Mill Family. Established in 1987 as a joint venture between Nucor Corporation and Yamato Kogyo, Co., NucorYamato Steel was founded on a commitment to revolutionizing the production of structural steel sections in North America.

Latest Posts

- معلومات عن آلات سحق وتصنيف

- منجم الفحم مصدر نقطة الخلفية

- تكلفة إنتاج multiwire آلة الجرانيت

- جنوب أفريقيا المعادن غرامة الفك محطم

- نيجيريا المحاجر المطاحن

- مطحنة استكشاف الأخطاء وإصلاحها

- تستخدم كتلة آلة صنع في الهند

- قائمة مطاحن MTM

- آلة تجفيف الرمل سعر الرمل آلة تجفيف الرمل

- الصين أكبر كسارة VSI

- مكونات الفحم مفرغ

- محطم مصنع عينة البرنامج الشعبي

- تستخدم كسارات الصخور المحمولة للبيع من الصين

- الصين معدات تكرير الذهب للبيع

- بي 2500 الأسطوانة مطحنة

- Diy Highbanker Dredge Combo Plans

- Mobile Sand Dryers South Africa

- Metal Sand Making Maechin

- Bauxite Flotation Ions

- Iron Ore Bucket Machines

- Emco Mill F1 Cnc Mill Only Accepts 200 Lines Of Code

- Primary Stone China

- Metrotrak Jaw Rock Crusher

- Cobblestone Hydrolic Break System Large Spring Cone Crusher Pyb175

- O Ide Jaw Crusher

- High Vol Met Coal Projects For Sale

- Almond Grinding Machine For Sweets

- Crusher Dealer Di Nevada

- Compound Fertilizer Making Equipment

- Buy Used River Sand Pump Machine From Germany