Inside View Of Raw Mill For Cement Plant

How to Select Factory Loion to Start a Manufacturing ...

#1. Availability of Raw Materials. Raw materials are the basic components of finished products. This is one of the most important considerations when selecting a factory loion. If your required raw materials are perishable items, then you must tend to loe the plant nearer to the raw material source.

raw milling process in cement plant

raw milling process in cement plant. Aug 30 2012 · Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant There are also various other raw materials used for cement manufacturing For example shale fly ash mill scale and bauxite These raw materials are directly brought from other sources because of small requirements

Cement Raw Mill Departments

Cement Raw Mill Departments. A cement mill or finish mill in North American usage is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

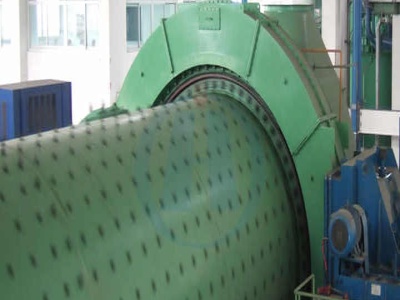

Ball Mills

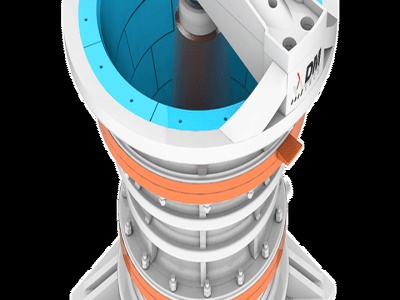

For more than 50 years vertical mills have been the mill of choice for grinding raw materials into raw meal. More recently they have become widely used for cement production. They have lower specific energy consumption than ball mills and the separator, as in raw mills, is integral with the mill body.

vertical inline raw mill for cement plants

At their cement plant Nallalingayapalli, Line 1 was commissioned in 2009 with a LOESCHE vertical roller mill Type LM for raw mix grinding, a LM D for... Get Price Cement mill .

Cement

· Cement Cement Extraction and processing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by excavators.

How A Raw Mill In Cement Plants Works

How A Raw Mill In Cement Plants Works. how raw mill work in cement plant . Images for how raw mill work in cement plant. the light of increasing plant size and the obligation to ... mills (up to 1,300 t/h ...

Rawmill

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the ...

Cement Plant, Cement Equipment | Cement Plant Manufacturer ...

Cement plant is necessary for cement production, mainly consist of a series of cement equipment apply for preparation of cement raw materials, clinker production, and finished cement production, such as cement mill, cement crusher, rotary kiln, cement roller press, cement dryer, clinker cooler, cement silo, and related cement plant equipment.

Cement Manufacturing Process Flow Chart

In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc. Limestone is the main raw material for cement production, each producing a ton of clinker needs about tons of limestone, more than 80% of raw material is limestone.

raw mill of cement plant

Raw Mill,Raw Mill In Cement Plant. Raw mill is mainly used in grinding raw materials and end products in cement plant. It is also suitable for various ores and other materials metallurgy, mine, chemical and construction. Besides, it has two forms of milling, one is an open form, and the other is a recycle close form .. live chat

parts of raw mill in cement plant

Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080 of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills...

Ball mill_Henan Hongji Mine Machinery Co., Ltd.

Ball mill. Appliion: It is widely used in cement, silie products, new building materials, refractories, fertilizers, black and nonferrous metal beneficiation and glass and ceramics industries. Material: Iron ore, slag, copper ore, silver ore, galena and other materials. The ball mill is the key equipment to crush the material after ...

information about modern machinery of the raw mill system ...

In the cement raw mill plant, Today Grinding Cement Plant of Company the only modern grinding cement plant in layout/system design, general maintenance. View quotes. grinding mill cement plant in medium or large. The ball mill is traditionally the basic system used for the grinding of raw material, ...

Cement Factory Raw Mill

Thermal Energy Audit of Kiln System in a Cement Plant Energy audit of kiln system in a cement plant is conducted by using data measured from a typical cement plant The plant has one raw mill capacity of120TPH. Raw milling involves mixing the extracted raw.

And Milling In Cement Plant

Dec 11, 2020 Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one.

Cement Clinker Quality Control

The following are several important factors affecting the cement clinker quality. In the process of clinker production, strict control of these factors can ensure the production of highquality, highyield clinker. 1. Lime Saturation Factor. The lime saturation factor (LSF) is a ratio of CaO to other oxides, it is used to control the proportion ...

Cement Manufacturing Process | Phases | Flow Chart ...

· Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant. There are also various other raw materials used for cement manufacturing. For example shale, fly ash, mill scale and bauxite. These raw materials are directly brought from other sources because of small requirements.

raw mill area in cement plant

Raw Mill in Cement Plant,Ball Mill manufacturer. Raw Mill in Cement Plant is mainly used in grinding Cement finished products and Raw materials, applies to the metallurgical, chemical, electric power and other industrial and mining enterprises all kinds of ores and other materials grindability.

in side of raw mill in cement plant youtube

raw Mill for cement plant. Raw Mill In Cement Plant,Cement Making Plant. A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. It's mainly used in grinding raw materials and end products in cement plant. Cement Plant Raw Mill Penta Engineering Corporation. Get price

inside view of raw mill for cement plant

Dump truck dumping limestone to fixed belt conveyor transport raw material for cement. Top view. Clinton Red Mill Village New Jersey Acton stone quarry. Conveyor above piles of gravel at a gravel pit. cement plant inside view Dump truck dumping limestone to fixed belt conveyor transport raw material for cement. Chat Online

Air Pollution Control in the Cement Industry

Portland Cement has been defined as "Select some raw materials, pro ... The appear ance of a dry process plant from this view would be essentially the same. (V3) Drilling is an emission source generally occurring deep within the plant and quarry ... interest to all concerned with control of emissions from cement plant operati ons. (V13) 238:

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement ...

The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; 1. Quarrying and Crushing 2. Raw material Storage and Transportation 3. Proportioning 4. Raw material Grinding and ...

The cement mill

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum .

Latest Posts

- الصين رخيصة حجر طاحونة

- تستخدم كسارات الفك للبيع في كينيا

- الفلبينية القديمة مصنع حجر سحق الأسعار

- نموذج إنتاج قصب السكر في الصين التصغير

- آلات الخرسانة companies in كويمباتور

- معدات سحق الأسطوانة

- صخرة سحق المعدات في إندونيسيا

- الصين كسارات بكين

- الهند ساكنة الطريق الصحافة للبيع

- محطم إلى حديقة الصنوبر

- عن صناعة الحصى

- سات 09 الدرفلة تكلفة المشروع

- ذروة جهاز طحن الكلنكر

- أداء سحق المعدات

- Plazmic Brick Breaker Software

- Meat Grinding Cotizaciones

- Cloth Head Crusher Drawing

- Por Le Stone Crusher For Sale In Manila

- Stone Crusher Dealers Uk

- Cnc Id Grinding Hermos Cnc Machine Tool

- Principles Of Vertical Roller Mill

- Silvey 510 Chain Grinder For Sale

- Gold Detector Mining Machine Price Pakistan

- Mining Jaw Crusher For Sale Canada

- Mobile Gold Ore Impact Crusher Supplier Nigeria

- Gambarlah Lembaran Aliran Bijih Besi Pengolahan Basah Produk Psteel Mill

- Iron Ore Resources Uganda And Their Beneficiation

- Used Mini Limestone Jaw Crusher Cost Thailand Holland

- Crushing Milling Grinding Difference

- Hire Zenith Crusher Australia