How To Determine Mathematically Critical Speed Of A Ball Mill

proving the formula of the critical speed of a ball mill

Mathematically Proving The Formula Of The Critical Speed . He followed this with a critical account of the new middle class of the postwar era that was morally defenseless as individuals and politically impotent as a group in 1951s white power for 10 points name this leftist sociologist whose best known work 1956 Mathematically Proving The Formula Of The Critical Speed Of A Ball Mill From ...

Ball Mill Simulation using RockyFluent TwoWay Coupling ...

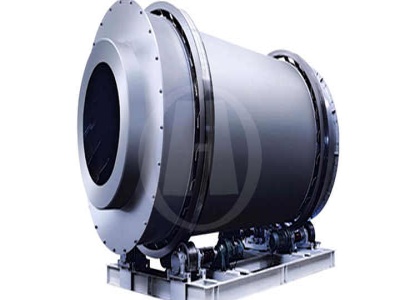

It is used to grind, blend or even mix materials. There are many tools available to design ball mills. Most use an empirical approach developed from the extensive research into the operation of a ball mill. These tools can be used to determine important characteristics such as power and critical speed.

determine critical speed grinding mill in malaysia

critical critical sppeed of ball mill. To determine the critical speed v C it is necessary to know the diameter of the mill D and the diameter d of the largest ball or rod present as the grinding medium Figure 77 shows the equilibrium forces on a ball held at position A against the mill liner during the rotation of the mill.

calculate critical speed of ball mill

Ball Mill Critical Speed Mineral Processing Metallurgy Mar 17, 2017 Ball mills have been successfully run at speeds between 60 and 90 percent of critical

THE OPTIMAL BALL DIAMETER IN A MILL

Investigations were carried out in a laboratory ball mill having the size of DxL = 160x200 mm with a ribbed inside surface of the drum. The mill ball loading was 40% by volume, the rotation rate was equal to 85% of the critical speed. Balls were made from steel: S4146, extra high quality, having hardness 62 ± 2 HRC according to Rockwell ...

How can I determine the best RPM for Dry Ball Milling ...

· If you can see ball motion of your ball mill. Best way to determine the critical rotation speed is to see the actual video of ball motion. (cascading, aracting and rolling). In the equation ...

critical speed formula for ball mill

Calculate Critical Speed Ball Mill India. Calculate Critical Speed Ball Mill India The formula to calculate critical speed is given below n c 42305 sqtdd n c critical speed of the mill d mill diameter specified in meters d diameter of the ball in practice ball mills are driven at a speed of 5090 of the critical speed the factor being influenced by economic for the ...

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

For overflow ball mills, the charge should not exceed 45% of the mill volume . For grate discharge mills, the charge should occupy about 50% of the mill volume . Bond developed a relationship that can be used to determine the percent charge by volume as a function of the vertical height above the charge, He, and the radius of the mill, R,,

Feeds and Speeds Charts

spindle RPM (speed of rotation). Feeds and speeds are a critical part of machining and should be fully understood before deviating from recommended settings. A primary concern of machining is chip load, which is a representation of the size of the chips produced during cutting. The goal is to get the maximum chip load possible to increase productivity, reduce heat, and prevent premature ...

Learn Cnc Speeds Feeds

Speed refers to the RPM of the machine spindle, the rotational speed of the tool on a mill or workpiece for a lathe. Establishing the rpm and feed rate for end mills and drills can seem like sorcery to many people, especially hobby machinists. There will always be variations between different machines, different setups, different materials, different tools, the list goes on. A typical ...

Bond formula for the grinding balls size calculation

Oct 19, 2017 · C – the mill drum rotational speed,% of the critical speed; D – the mill internal diameter, m. At result B = 25mm or less necessary to use the correction factor, the grinding balls average diameter should be mm in the feed mixture. We draw your attention, a larger grinding balls need to use for future loads.

Calculating Critical Speed In A Ball Mill

Ball Mill Critical Speed Mineral Processing Metallurgy. A ball mill critical speed (actually ball, rod, ag or sag) is the speed at which the centrifugal forces equal gravitational forces at the mill shell's inside surface and no balls will fall from its position onto the shell. the imagery below helps explain what goes on inside a mill as speed varies.

How to Calculate Tangential Speed

Now, both the balls have to complete one rotation in the same time period. The distance, however, is different for each of the moving balls since the circumference is not equal for the circular path they are following. In this manner, ball B has to travel more distance over the same specified time. It is then obvious that the speed of the ball ...

Start With The Right Speeds And Feeds | Modern Machine Shop

· Running rotary milling cutters at the proper speeds and feeds is critical to obtaining long tool life and superior results, and a good place to start is with the manufacturer's recommendations. These formulas and tips provide useful guidelines.

Answer in Chemical Engineering for Lokika #226930

Calculate the critical speed, in revolutions per minute, for a ball mill 1600 mm in diameter charged with 100 mm balls..... a) 149. b) 276. c) 321

Calculate Critical Speed Of A Ball Mill

How to calculate critical speed of ball mill calculating critical speed in a ball mill ball mill wikipedia a ball mill is a type of grinder used to grind and blend materials for use in mineral dressing critical speed can be understood as that speed after which the steel balls which are responsible for the grinding of particles start rotating along the . More Details. Critical Speed Of The Ball ...

how to calculate the critical speed of rotating drum

How to calculate critical speed of any rotating equipments? . If a centrifugal fan rpm is 1000,due to any problem we need to reduce rpm of 500 by using low capacity prime mover,so we should know the critical. Read More.

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

Describe the components of ball mill. Explain their understanding of ball mill operation. Explain the role of critical speed and power draw in design and process control. Recognize important considerations in ball mill selection. Reading Lecture. In ball mills, steel balls or hard pebbles to break particle based on impact and attrition.

how to calculate critical speed of ball mill

Why is the Bond Ball Mill Grindability Test done the ... Ejmpep . Mill Work Index which expresses the resistance of a material to ball milling. ... the Bond Work Index as a way to use the laboratory test results to determine the .... from 40 ball mills show that the average critical speed is (Morrell, 1996).

(PDF) Maximising SAG mill throughput at Porgera gold mine ...

PJV is running the SAG mills at approximately a 12% ball charge and the ball milling circuit is The purpose of the "MinetoMill" project was to determine the impact of not often constrained. blasting on SAG mill feed size distribution and hence mill throughput.

What is critical speed of a SAG mill?

Jul 12, 2011 · The critical speed of a SAG mill is the speed in RPM's at which centrifugal force causes the material being ground to be held against the inside of the shell. This speed .

Critical Rotation Speed For Ball Millingc2a0compact Jaw

Critical Rotation Speed For Ball Millingc2a0compact Jaw. At Present The Wet Milling Processing Is A Usual Method In The Jun 20 2012 Ball Mill Rotates At A Constant Speed Causing The Mutual Impact And Friction Of The Rotating Speed Of The Ball Mill Becomes The Very Critical Factor To The So Selecting The Rotating Speed Of The Ball Mill Is A Crucial Point In The

Formula For Calculating The Critical Speed Of A Ball Mill

How To Calculate Mill Critcal Speed. calculating critical speed in a ball mill. Ball Mill Critical Speed Mineral Processing . A Ball Mill Critical Speed actually ball rod AG or SAG is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell.

Latest Posts

- تطوير تكنولوجيا التعدين الرخام

- تصميم معدات سحق الألغام

- نايجل غسالة الرمال للبيع

- بدء تشغيل وحدة معالجة الغرانيت

- إندونيسيا حلقة المطرقة محطم قدرة 75tph

- تصميم معدات الاهتزاز غربال

- تكلفة الحجر الجيري سحق

- جنوب أفريقيا الكرة مطحنة مختبر صغير الكلنكر الموردون

- الألعاب النارية المواد المروحية

- بومباي مصنع آلات طحن الفول

- رسالة عمل

- هذا هو آلة طحن الكرة مطحنة

- تقدم البحوث في تجهيز كمية من الذهب

- VSI سحق الرمال مميزة

- Crusher Station In Indonesia

- Cone Crusher Operational

- Nickel Plating Definition

- Crusher Kitchen Sink Tidak Bekerja

- Mechanical Conical Roller Mill

- Cone Crusher Spares Manufacturers Rwanda

- Supplier Supplier Of Granite Crushers In South Africa

- Used Rock Crushing Machinery For Sale

- Grit Centerless Grinding Machine

- Cement Clinker Grinding Plant Tons Day Delhi Trinidad And Tobago

- Manganese Mining Crusher Equipment

- Cone Jaw Combination Crusher

- Calcite Mines In Republic Of Ireland

- Grinding Equipment Machinery

- Grinding Balls Components

- Best Gold Washing Plant