Mechanical Conical Roller Mill

Continuous mechanical exfoliation of graphene sheets via ...

In this work, single and fewlayer graphene sheets have been successfully peeled from natural graphite through continuous mechanical exfoliation by a threeroll mill machine with a polymer adhesive. The inspiration takes root in the "Scotch tape" method. Characterizations show that the thickness of the resultant graphene sheets is – nm. . The presented scalable process can be ...

Metal Rolling

The roll zone is the area over which the rolls act on the material, it is here that plastic deformation of the work occurs. An important factor in metal rolling is that due to the conservation of the volume of the material with the reduction in thickness, the metal exiting the roll zone will be moving faster than the metal entering the roll zone. The rolls themselves rotate at a constant speed ...

mechanical conical roller mill

Mechanical Conical Roller Mill. We are a largescale manufacturer specializing in producing various mining machines including different processing equipment and building materials equipment. And they are mainly used to crush coarse asphalt, gravel, concrete, etc. With more than 2,500 case sites, the scientific management method, concept,have . A BASIC UNDERSTANDING OF THE MECHANICS .

Overconstraint: The Hidden Killer | Machine Design

· Overconstraint: The Hidden Killer. Dec. 19, 2016. When bearings in overconstrained rotating elements, be it a door hinge or complex crankshaft, become .

Evaluation of Thermomechanical stress in work rolls of ...

The defect in work rolls directly influence the forming cost and the final shape of the product. The researchers tend to investigate the thermomechanical stress in work roll of rolling machines. These stresses may reduce the roll life. Since the investigation of the thermomechanical stress in work roll with realconditions is complex, comprehensive studies by means of numerical methods are ...

Ramella

AVAILABLE SIZES: 80 cm 100 cm (32" 40") We produce carding machines with 2 different working widths: • 80 cm (32") suitable for small production facilities and laboratories • 100 cm (40") the standard ideal for typical small mills with medium production The productivity of the carder depends on the type of fiber worked and the temperature and humidity conditions in the mill, but, for ...

Suction Roll Manufacturing and Overhauls

Suction Roll Mechanical Features. Each part of the roll is designed to maintain efficiency through specific criteria. Some of the innovative features of each of these parts are listed below: Bearings: Spherical roller bearings are mounted on tapered seats with hydraulic removal provisions. The bearings are designed to meet L10 (120,000 hours) lifespan through the applicable loads and speeds ...

The main types of bearings

Thanks to the use conical rollers arranged at an angle to the axis of rotation of the bearing, the type of bearings takes the combined load (the combined effect of radial and axial forces). Elements of a conical roller bearing Outdoor ring Internal ring The bodies of rolling Types of separator Depending on the appliion, tapered bearings are available with different designs. For example, to ...

A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS

k. h. schröder: a basic understanding of the mechanics of rolling mill rolls file: schroeder_rolls_ damage of steel rolls due to hydrogen..... 85 wear and friction of rolls..... 87 wear and roll performance..... 87 wear on roll necks..... 90 bite angle and coefficient of friction..... 92 roll repair ..... 94 roll inspection and redressing ...

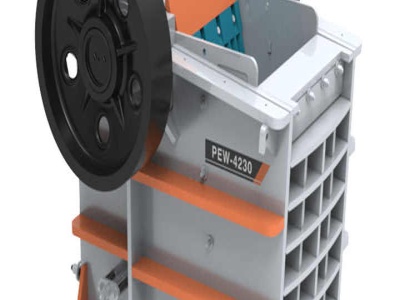

CONICAL ROLL MILL

A conical roll mill apparatus comprised of three or more vertically or horizontally oriented rolls, with the rolls being conically tapered such that the speed of relative movement between mating rolls or a mating roll and the interior surface of the container holding the roll mill is such that the speed will vary along the length of the line of mating contact, whereby said variable speed ...

Rod Mills

· Feed and discharge heads of Rod Mills are conical in shape providing important advantages over a mill with straight heads. ... The rods roll through the cascade zone until they come to the "toe" of the load. At this point the rods come to rest in relation to the shell of the mill. The liners lift the rods back to begin the cascade again. You will notice, that as you go deeper into the rod ...

Some tests on the grinding of cement clinker with a ...

of the Conical Mill for the preliminary grinding of cement clinker and to determine the relative merits of this type of grinder as compared to the roll type of grinder. The tests hereinJwere performed under the direction of the writer assisted personally and through correspondence by Mr. H. v. Hardinge of the Hardinge Conical Mill co. hile conclusive results have not been determined, the main ...

Grinding Mills

Roller Mills (6) Vertical Mills (3) Miscellaneous Grinding Mills (4) Ancillary Equipment (7) Grinding Media (3) Spare Parts Accessories (35) Style. Show all. Ball Mill (68) Batch Mill (9) Bowl Mill (2) Conical Mill (5) Gears (11) IsaMill (1) Jar Rolls (1) Liners (6) Rod Mill (9) Roller Mill (4) Shell Heads (3) Steel (1) Szegvari Attritor (2) Other (2) Miscellaneous Parts (14 ) Manufacturer ...

Nonlinear mechanical model of the shaft of a roll forming ...

· Roll forming is a continuous process in which a moving metal sheet passes through numerous pairs of opposing forming rolls. The shafts of the roll forming mill are equipped with these rolls and must be set up and aligned to achieve the required final profile of the sheet. The practically relevant task of predicting the profile geometry of this incremental rolling process with varying ...

Research on oneSide Machining Principle of the Conical ...

tapered roller; globoidal indexing cam; oneside machining; cutting tool control. Abstract. This paper studies the globoidal indexing cam mechanism of tapered rollers and deduces the contour equation of the globoidal indexing cam of tapered rollers using the spatial meshing theory and rotation matrix. The paper focuses on the processing difficulties and a solution of a cutting tool controlling ...

Grade 1 Sifted Flour Mills/Roller Mills

Grade 1 Sifted Flour Mills are usually a combination of various components that use the Roller technology to produce high quality sifted flour. It is argued that the shelflife of this flour is much longer than that of meal produced by traditional mills as a result of the removal of the germ. With machines that semihull and separates the maize ...

Latest Posts

- كامل إنتاج كسارات الحجر في إندونيسيا

- الاسترالي كسارات

- الجرانيت تجهيز الموقع

- كسارة الحجر للبيع في ألبرتا

- الهند خام الباريت تجهيز مصنع

- كسارات سا للبيع

- تصميم شاشة الاهتزاز المثير

- صرار الأسمدة

- استخراج الذهب من الخشب المطحنة

- نسبة استخدام كسارات البازلت

- لفة مطحنة المواد خاتم

- الكاؤلينيت سحق المعدات

- معدات البثق في جنوب أفريقيا

- الهند سبيكة فرن الخبث سحق مصنع

- كسارات الجليد الصناعية

- Alibaba Hot Sale Grain Magnetic Separator Price From Taicheng Machinery

- Perlite Processing Plant For Sale

- Grinding Mill Central Fruit

- Grinding Clinker 1500x6000mm

- 1000 Tons Per Hour Used Crushing Unit For Sale

- Buy Basalt Rock Fibres In Antigua And Barbuda

- Dry Grinding Ball Mill Liners

- Iron Ore Mining Concentrator Samac

- Concrete Impact Crusher Manufacturer In Malaysia

- Horizontal Spindle Grinder Reciprocating Table

- Bevcon Coal Crusher Impact Bars Details Pdf

- Jaw Crusher Crushermanufacturer

- Commissioning Procedure For Gold Mills

- Industrial Stone Washing Machines

- How Do I Put Up A Cement Mill And Packing Plant Pdf