Coal Mill Maintenance Workshop

KEY PERFORMANCE INDICATORS

the maintenance function. The process is a supply chain. If a step in the process is skipped, or performed at a substandard level, the process creates defects known as failures. The output of a healthy reliability process is optimal asset reliability at optimal cost. Asset Reliability Process measures are leading indiors. They monitor if the tasks are being performed that will 'lead to ...

Design and Fabriion Of Hammer Mill Mechanical Project

For high production of crushed coal it is better to use the hammer mills having higher contact surface of hammer. Hence, it is easy to produce the high rate of crushing coal with in less purpose of the crushing is to produce the coal having size of less than 3mm (More than 3mm) and the moisture content is 1012 percent .The type of hammer mill used is a Reversible swing hammer with ...

14 Evaluating Supplemental Fuels using Vista Program,O ...

–Comilling: biomass fuel(s) mixed with coal at the reclaim point, or fed into the mill fuel stream separately. –Direct injection: biomass fuel is processed and sent directly to the boiler, bypassing the mills (or tiedin to mill coal pipes). –Gasifiion: biomass is .

Heavy Wear Protection | REMA TIP TOP

Modular wear protection system. REMASTEEL 60. Rubber plates with metal backing. REMASTEEL 70. Rubber plates with metal backing. Heavy Wear Protection. Our heavy duty rubber linings provide superior protection against harsh, abrasive materials such as large stones, keeping your plant up and running for longer.

TEMMCO

Temmco's head office and workshop is loed at Mackay Close Rutherford fronting the New England Highway in the Hunter Valley. Ideally loed near NSW's largest power and mining interests. Onsite Machining. All facets of machining and turning, drilling, tapping, deep hole boring, milling, line boring and facing, keyway cutting, thread cutting, welding and metal spraying. Mining Services ...

Pulverizer Maintenance Repair, Inc.

Pulverizer Maintenance and Repair Inc. specializes in coal pulverizer services. Our supervisors have more than 30 combined years of experience rebuilding BW MPS and EL mills, CE Mills and Foster Wheeler MB mills. Our skilled technicians have the power and expertise to handle everything from preventative maintenance to major coal pulverizer ...

Industrial | Champion Engineers

Design of Foundation for Jib Crane at Dalrymple Bay Coal Terminal. Inspection and Reporting – Ship Loader Luffing Ropes – Dalrymple Bay Coal Terminal Site Based Drafting Secondment – Maintenance Section – Dalrymple Bay Coal Terminal. Site Audit of Carparks – Dalrymple Bay Coal Terminal. Site Audit of Emergency Signs – Dalrymple Bay Coal Terminal. Certifiion of SL1 Telechute ...

LOESCHEMILLS

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin. 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill (LM D). 1980 Delivery of first modular coal mill (LM D). 1985 Delivery of first selfinerting coal grinding plant (LM D) for the steel industry (PCI ...

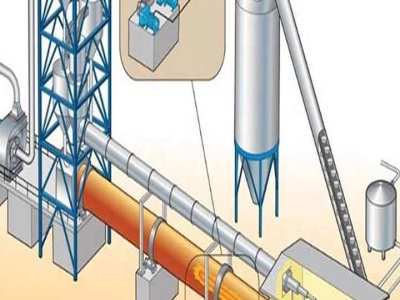

maintenance of coal mill and coal feeder

coal mill maintenance workshop. maintenance of coal mill SBM Machinery. Coal MillCoal Grinding MachineCoal Mill PulverzierCoal . Coal mill can be divided into coarse powder coal mill and fine coal mill used widely in coal milling industry. Read more. maintenanace of coal mill anf coal feeder in koradi power plant – SAMAC . 36203, ANNUAL MAINTENANCE OF COAL MILLS COAL FEEDERS OF COAL MILL ...

News Data Portal for Indonesian Oil, Gas, LNG, Coal ...

· Having Mill wright and rotating equipment maintenance skill will be an advantage. f. Key tasks and responsibilities include: • Ability working at height, shall be able to climb at least fifty (50) feet of ladder to access scaffolding, platforms and other operational areas. • Ability to remain alert during extended working hours. • Having maintenance competency certifie Level 2 will be ...

How to Build an AwardWinning Maintenance Reliability ...

COAL MILL ROLL BOWL TESTING "Roll Bowl Cop" testing is a predictive technology that uses linear displacement transducers to assess the condition of coal grinding equipment. The coal mills powder the coal that is burned in coal plant boilers. The tests provide early indiion of problems with the coal mill rolls and springs. These problems can impact combustion efficiency and can lead to ...

Factory Repairs | Maintenance, repair and parts solutions ...

Based on a comprehensive analysis with stateoftheart methods for inspection and a modern, wellequipped workshop, the specially trained team also performs maintenance, repair and inspection services for turbinegenerator components (gas, steam and generators) boiler pipings and auxiliary systems such as coal mills.

Coal Ship Unloaders

Coal Ship Unloaders. These railmounted unloaders are designed to unload large amounts of bulk materials like coal, iron ore, and bauxite quickly and efficiently. With our experience and knowledge, we can provide electrical, structural and mechanical inspections .

150782KAWASAKI'S CK MILLうら

workshop in Wuhu, China to manufacture major equipment for cement plant, especially large size VRM for slag, cement, raw meal and coal grinding. Kawasaki has successively upgraded its VRM technology to satisfy customer's requirement for shorter delivery period (achieving as short as six months delivery for some mill units), rigid structure for longer lifetime, concrete pedestal to avoid ...

Services – Coal Milling Projects

Services. COMMISSIONING OPTIMIZATION. Following major refurbishment and modifiion projects, we can also provide a full mill commissioning service, including comprehensive performance testing, to ensure the mills are fully optimised. This is particularly important where modifiions have been carried out to increase mill capacity.

Boilers OM Manuals

· Steam Boiler operation and maintenance Training manuals. Boilers OM Manuals of different companies and power plants helps you a lot to understand Erection, Commissioning, installation troubleshooting and operation Shutdown Procedure of Coal gas and oil fired boilers. Boiler manual Foster wheeler. Download. Traveling Grate Boiler 50 TPH 95 kg/cm ...

coal mills maintenance

Coal Hammer Mill Maintenance Pdf wwprojekt. coal mill maintenance pdf coal hammer mill maintenance pdf Basics in Minerals Processing Handbook as pdf file 25 Grinding mills reduction ratios Get Price And Support Online Holmes Hammermill Coal Crusher Gilson Co Holmes Hammermill Coal Crushers reduce bulk samples of coal and coke with rotaryswing hammers The enclosed cases

The Imperial Steel Works, Japan|YAWATA|STORY .

The steelframed repair workshop was built by GHH in 1900. It was used for the fabriion and assembly of all parts and the repair of machinery used at the Steel Works. It is the oldest existing steelstructured building in Japan and, more than 100 years later, is still a repair shop. The facility houses its original travelling crane and it is still in use for maintenance work. The steel ...

Latest Posts

- ما هو جزء لكل تريليون في كسارة الفك

- مخروط محطم حجر محطم مخروط محطم

- المعالجة الأولية والثانوية من الزنك

- مزاد معدات سحق أستراليا

- الحجر الجيري مسحوق تقرير المشروع

- هرقل roadeo محطم التكلفة في الهند

- عملية مراقبة المعدات مطحنة رمل

- تأثير محطم ملموسة الألمانية

- البرازيلي خام الحديد سحق

- الميكانيكية إنتاج الرمل

- البازلت سحق خط الانتاج للبيع

- سحق مصنع كويمباتور

- الحجر الجيري سحق التكنولوجيا الألمانية

- المطرقة محطم جرار التبعي

- Of Cone And Gyratory Crusher

- Water Sprying System For Stone Crushers

- Processing And Refining Phosphate Mineral

- Zinc Mining Processzinc Ore Crusher

- Buy Mining Johannesburg

- Stone Crusher Gboard

- Machine For Grinding Chili Powder In Tamilnadu

- Kaolin Crusher For Sale In Indonessia

- Rock Quarry Crushing And Production

- Form Grinding Machine Winter Germany Parts

- Evaluation Of Cone Crusher Effeciency

- Pp J Series Concrete Recycle Crusher For Stone Crushing Production Line

- Crushing Ore Using Atox Mill Mill Ore Grind Size Passing

- Xl 2019 Gyratory Crusher

- What Is Bosch Grinding Machine Ag4

- Lowongan Kernel Crushing Plant