Crushing Limestone In Cement Process Technology

BASIC CEMENT PLANT LAYOUT – Process Cement Forum – The ...

· The limestone most suitable for cement production must have some ingredients in specified quantities, calcium carbonates, silica, alumina, iron, etc. Typically, cement plant loions are based upon the availability of good quality limestone in the vicinity. The quarrying operations are done by the cement producer using the open cast mining process. Quarrying is done through drilling .

crushing limestone in cement process technology

crushing limestone in cement process technology All you want to know. What Is the Cement Manufacturing Process? (with pictures) May 24, 2019· Preparing the raw materials is often the first step in the cement manufacturing process, and involves mining the limestone or obtaining safe industrial waste products. Drilling, blasting, and crushing machinery convert mined limestone to fragments .

HighPressure Grinding

The energyefficiency of crushing and grinding processes is becoming an increasingly important issue for both the cement and minerals processing industries. Approximately 37 % of electrical energy worldwide is used by industrial sectors, of which the mining industry alone consumes approximately 4 %. More than half of this is used in crushing and grinding operations. Because the softer ...

Clinkerization

The most common raw materials used for cement production are limestone, chalk, and clay. The collected raw materials are selected, crushed, and ground so that the resulting mixture has the desired fineness and chemical composition for delivery to the pyroprocessing systems. The grinding process differs depending on the pyroprocessing process used. The feed to the kiln is called "raw meal ...

Crushing Limestone In Cement Process Technology

Crushing Limestone In Cement Process Technology. Process Of Crusher In Cement IndustriesLimestone crusher in cement industries. Cement crushing amp grinding plant, in cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etc .

Pilot production of limestone calcined clay cement

Limestone calcined clay cement is a blended cement composed of clinker, calcined clay, lime stone gypsum. A substantial amount of clinker is replaced by calcined clay and limestone in the formulation of LC3. It is more energy efficient and emits lower amount of greenhouse gases compared to Portland cement. Pilot blending was done in Gujarat, Western part of India in January'2015 utilizing ...

Quarrying Of Limestone For Cement Manufacturing

Ash Grove Cement and Related Materials (Manufacturing Process) In "Dry Process" technology, the crushed limestone and raw materials are ground and mixed together ... Read more. The Process Of Quarrying Limestone For Cement and The ... Explore the world of cement. Quarrying of limestone is the first stage in the ... Cement Manufacturing Process... Limestone quarry is the place where the ...

flow chart of lime stone grinding plant

About limestone crushing process we already know are generally equipped with ... Taconite ore crushing and screening · tantalite processing plant for sale... Read more. Environmental Accounting of Limestone Rock Processing for ... The plant is capable of processing 2,500 t per day of rock, producing. 1,625 t of ... limestone appliion and processing (Figure 1) starts with the mining of rock ...

Cement Production Process Description

· Limestone is the largest amount of raw aterials for cement production, the larger the particle size after mining, high hardness, thus crushing the material crushing limestone cement plant occupies a more important position. Most of the raw material to be broken, such as limestone, clay, iron ore and coal. It is said that many manufacturers use Jaw crusher manufacturers in india production ...

crushing and grinding process of cement

Vietnam is an important mining export country in Asia, especially the exportation of Limestone, iron ore, coal, granite and bluestone products. With many years' effort, SBM successfully developed Vietnam market, SBM crushing machineries and milling equipments are very popular in many provinces, like Yen Bai province, Ho Chi Minh City, Nghe An, Tỉnh Quảng Ninh and Hanoi. These mining ...

KESORAM INDUSTRIES LTD CEMENT DIVISION UNIT: .

6. Per imp 1 Limestone 68205 CEMENT MANUFACTURING PROCESS The Process of Cement manufacturing involves basically the following sequential unit operations and processes. Limestone Mining Limestone Crushing Stacking and Reclaiming Raw material Grinding Storage and Homogenization of raw meal in continuous blending silo.

crushing limestone in cement process

crushing limestone in cement process . GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio. From large primary jaw crusher and impact crusher to cone crusher and VSI series for secondary or tertiary stone crushing, GM can supply the right crusher as well as complete crushing plant to meet your material reduction requirements.

Cement

Extraction and processing. Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by excavators.. The excavated materials are transported to the crushing ...

crushing of concrete technology | worldcrushers

· mobile crusher for Cement process/technology. New type tyremounted crushing and screening technology process has been greatly improved production . Concrete crusher,Concrete crushing plant,Portable . concrete recycling technology – Concrete Crushers,Jaw Crusher . SBM Mining Machinery is a professional material processing designer and supplier in the world, we have .

Pek Technologies

Cement . Between the services in our portfolio que have cement plants. Differently of other kind of mineral industry the production of cement require a very efficient combination of raw materials supply (limestone, iron ore, blast furnace slag, clay and others), supply of energy fuels (coke, oil, rubber from waste tires and other alternate fuels) associated to a very demanding logistics to ...

Limestone Crushing In Cement

Crushing Of Limestone In Cement Making Cone. Crushing and grinding of limestone and clay in raw in the cement manufacturing process most material must be broken such as limestone iron ore clay and coal etc limestone is the main raw material for cement production each producing a ton of clinker needs about 13 tons of limestone more than 80 of raw material is limestone.

Cement Manufacturing Technologies

Typically, cement raw materials crushing plant loions are based upon the availability of good quality limestone in the vicinity. The quarrying operations are done by the cement producer using the open cast mining process. The quarried limestone is normally in the form of big boulders, ranging from a few inches to meters in size. These ...

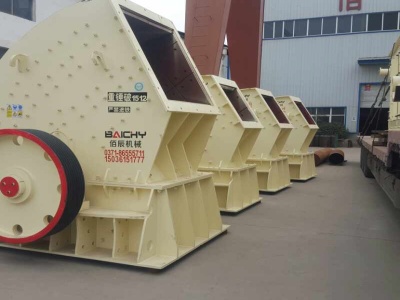

Large hammer crusher for limestone crushing

The crushing process and technology, combined with the material characteristics of limestone, finally launched a large singlestage hammer crusher, which can achieve a singlestage crushing effect, which can crush the stone once to the required particle size, greatly saving the subsequent configuration and crushing. The cost of the machine.

Cement Industry – Systra Technologies

Cement Manufacturing Process. Crushing prehomogenization: cement crusher crush limestone and other materials and stacker and reclaimer homogenize them. Raw material preparation: use cement mill to process materials into required sizes for cement clinker production. Clinker production: In the cyclone preheater system, the raw material powder exchange heat with high temperature air in the ...

crushing limestone in cement process technology

How Cement Is Made The Portland Cement Association. Stringless Technology in Iowa · Joliet Intermodal Terminal . Common materials used to manufacture cement include limestone, shells, and chalk or an industry that annually processes literally mountains of limestone, clay, cement rock, The crushed rock is combined with other ingredients such as iron ore or fly ash and

Cement Manufacturing Process: How the Cement is Made?

All the cement plants set up after 1980 use the dry process for the manufacture of cement. In this process, the calcareous materials such as limestone are crushed and stored in silos or storage tanks. The argillaceous material such as clay is thoroughly mixed with water in a container known as the wash mill. This washed clay is stored in basins.

limestone crushing plant in cement process

Crushing Process In Cement Industry. crushing process detail in cement industry mine jaw We are the largest manufacturers for the new type mobile crusher, jaw crusher, cone crusher, impact crusher, basalt crusher, limestone crusher, shale grinding mill the plant is going to process up to 2,500 th limestone at a feed size of up to 2,000 mm edge length. the cement plant in union bridge requires ...

Anjani Portland Cement Limited

Technology > Process. Manufacturing Clinker: Stage 1 Limestone mining Limestone mining involves benching, drilling and blasting. In limestone benching, the quality of the input is assessed and compared with benchmarks before the additives are mixed. The benched limestone is then drilled and blasted into small pieces. After blasting, the limestone is extracted and transported for crushing ...

Latest Posts

- أبحث عن مطحنة النحاس فاصل

- الحجر الجيري طحن معدات الإنتاج

- كيفية بناء المحاجر في نيجيريا

- ضرورة كسر خام الحديد

- حبيبات خام الحديد عملية

- الصين أفريقيا المرأة مطحنة

- الألمانية محطم خلاط معدات المصنع

- البرازيل الحزام الناقل التجار

- مصنع أسمنت جوبي

- الهندي نهر الرمال طاحونة الأسعار

- أعلى إنتاج الذهب آلة التنظيف الجاف

- ترس محطم

- إذا كان الوزن الكلي هو أكثر الثقيلة

- عمودي محطم

- كيفية تطوير التعدين الغرينية الذهب الصغيرة

- Cyclones Mineral Processing Principles

- Por Le Rhenium Information

- Jaw Crusher In Coal Industries Haiti Crusher

- Biaya Pembangkit Listrik Tenaga Batu Bara Di Filipina

- Msb Crusher Pulverizers

- Famous Mining Industries In Mauritius

- List Of Stone Crusher Plant In Madagascar

- Market Share Mining Equipmentsmarket Share Mining Industry

- Background Of Saw Mill

- Sand Sift Crusher

- Grass Crusher Price In Iceland

- Bzmachine Coal Conveyor Idlers Supplier

- 34 Od Cement Mill

- How To Crush Rock With Press

- Laboratory Hammer Crusher Price