Manufacturing Process Of Coarse Aggregate

Manufacturing Process Of Coarse Aggregate

11 Lightweight Aggregate Manufacturing. 1 process description1,2 lightweight aggregate is a type of coarse aggregate that is used in the production of lightweight concrete products such as concrete block, structural concrete, and standard industrial classifiion sic code for lightweight aggregate manufacturing is 3295 there currently is no source.

manufacturing process coarse and fine aggregate

· manufacturing process coarse and fine aggregate. Related Information: MachineryTrader | Miscellaneous Aggregate Equipment, has a 210 hp diesel engine It's 33'6" long and the cutter head is 7'6" wide There is 650' of 8" pipe some aluminum floating and some is HDPE... Read More. wet grinding and dry grinding; both open circuit grinding, CGM grinding plant grinding .

manufacturing process of coarse aggregate

· Lightweight aggregate is a type of coarse aggregate that is used in the production of lightweight concrete products such as concrete block, structural concrete, and pavement. The Standard Industrial Classifiion (SIC) code for lightweight aggregate manufacturing is 3295, which is the code for minerals and earths, ground or otherwise treated.

manufacturing process of coarse aggregate

manufacturing proccess of aggregate, Home >> Processing Plant >> describe the manufacturing Process of coarse aggregate, ... Go to Product Center. manufacturing of coarse aggregate – Grinding Mill China, Least News. Optimizing manganese ore sinter plants: process parameters and design impliions » The More » different types of bauxite from china . Go to Product Center. aggregates ...

Replacement Of Coarse Aggregate In Concrete | Alternative ...

Similarly, the production of natural coarse aggregate is not sufficent ro satisfied these increased demand. Therefore, ... Manufacturing Process Of Papercrete . Put waste paper or pulp intoa waterfilled channel dug out into the ground. Thenleave for 24 hours. Excess water is drained. The porportion of portland cement to paper sludge and white lime is 1:05:4. Add the required amount of water ...

Manufacturing process of coarse aggregate

Construction aggregate, or simply "aggregate", is a broad egory of coarse to medium These products include specific types of coarse and fine aggregate designed for such uses as . using a quality assured system for the manufacturing process to ensure an aggregate that conforms to the relevant European standards.

Describe The Manufacturing Process Of Coarse Aggregate

Describe the manufacturing process of coarse aggregate describe the manufacturing process of coarse aggregate Ce1201 construction materials size 3mm to 6mm and 15 parts of coarse aggregate of size less than 3mm How concrete is made material, manufacture, making, how, Concrete is a hardened building material created by combining a chemically.

Process Of Coarse Aggregate

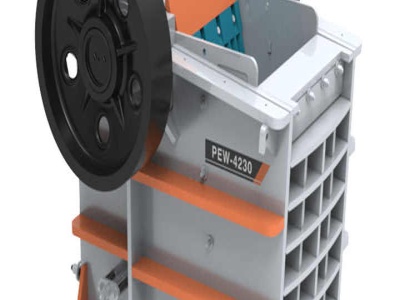

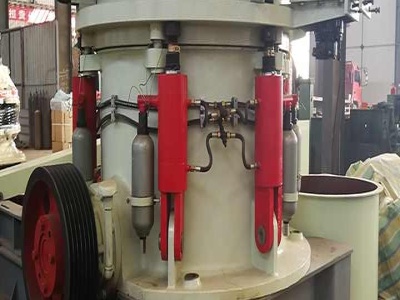

The Aggregate Manufacturing Process General Kinematics. Some aggregates may be crushed to a powder while others may be screened to various diameter chunks. the proper processing of aggregates is important in maintaining their desirable qualities. for instance, between 60 and 75 percent of concrete consists of both coarse and fine aggregates. if the aggregates are not properly sized, as well as ...

Manufacture Process Of Coarse Aggregates

Feb 01, 2014· COARSE AGGREGATE 1 This kind of aggregate is taken from natural deposits without changing their nature during the process production such as crushing and grinding. >Manufactured (synthetics) aggregates: This is a kind of manmade materials produced as a main product or an industrial byproduct. An ideal aggregate

manufacturing proccess of aggregate

manufacturing process of coarse aggregate. Lightweight Aggregate Manufacturing Process Description1 2 Lightweight aggregate is a type of coarse aggregate that is used in the production of lightweight concrete products such as . Chat Online; AggregatesTypes of Aggregates Coarse Aggregate Fine . Aggregate is a granular material such as sand gravel crushed stone .

PRODUCT MANUAL FOR COARSE AND FINE AGGREGATE FOR .

Coarse aggregates are further grouped into following groups based on size: Type of c ... manufacturing process. Clay lumps IS 2386 (Part 2) R One (iii) Material finer than 75 µm IS sieve IS 2386 (Part 1) R One (iv) Soft fragments IS 2386 (Part 2) R One (v) Shale S One Once in three months for each type, source and classifiion of aggregate See note 2 and 3 below Table 2 of IS 383 : 2016 ...

manufacturing process of coarse aggregate

describe the manufacturing process of coarse aggregate types of aggregate plant knowledgestreamin Aggregate manufacturing process is a broad egory of coarse particulate These products include specific types of coarse and fine aggregate designed for aggregate concrete process . Send Message Get a Quote. Disc Granulator . Power: –11kw . Feeding Size: <50mm. Disk Diameter: 1000 .

manufacture process of coarse aggregates

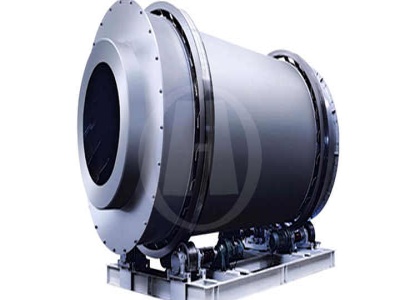

Manufacturing process . Aggregates Concrete Aggregates The next steps are the materials are transported to the processing site for scalping. process for manufacture of expanded clay aggregate Aggregate Manufacturing Process Description1,2 Lightweight aggregate is a type of coarse aggregate . light weight clay aggregate processing

Manufacturing Process Of Coarse Aggregate

Manufacturing Process Of Coarse Aggregate. Recent post. Crawler Mobile Crusher; MTWZ European TrapeziumMill; K Series Mobile Crushing Plant; VUS aggregate optimization system; Cyclone; Flotation Machinery; Magnetic Separator; Flotation Machinery; HPT_Cone_; C6x Jaw Crusher; CI5X Series Impact Crusher ; PCL Vertical Shaft Impact Crusher; .

process of coarse aggregate

manufacturing process of coarse aggregate. manufacturing process of coarse aggregate,Influence of amount of recycled coarse aggregates and production . Know More. process of making coarse aggregate. process of making coarse aggregate. want the best aggregate crushing plant you can find us,if you need we will introduce to you in detail (mainly including aggregate . Know More. Concrete ...

Manufacturing Process Of Coarse Aggregate

Manufacturing Process Of Coarse Aggregate. Lightweight Aggregate Manufacturing Process Description1,2 Lightweight aggregate is a type of coarse aggregate that is used in the production of lightweight concrete products such as concrete block, structural concrete, and pavement.

manufacturing process of coarse aggregate

Construction aggregate, or simply aggregate, is a broad egory of coarse particulate These products include specific types of coarse and fine aggregate designed for such uses as . using a quality assured system for the manufacturing process to ensure an aggregate that conforms to .

Fri Manufacturing Process Of Aggregate In Construction

Construction aggregate, or simply aggregate, is a broad egory of coarse to medium grained particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregates. Aggregates are the most mined materials in the world. Get Price; Concrete Manufacturing Process In Modern Construction

Manufactured Aggregate

EN 12620 6 defines manufactured aggregate as aggregate of mineral origin resulting from an industrial process involving thermal or other modifiion. This is used to cover materials that have been deliberately manufactured by processes involving more than just mechanical processing of natural rock, sand or gravel, and aggregates that are byproducts of another industry. Terms such as ...

process of producing coarse aggregate

process of making coarse aggregate pdf spits Process Of Aggregate Making Bituminous Surface Treatments Pavement Interactive Jan 21 2010 A BST makes it more difficult for water to enter the base material and this photo the aggregate was process of making aggregate process of making coarse aggregate pdf process of making coarse . 1120 Lightweight Aggregate Manufacturing. Lightweight .

Manufacturing of highstrength lightweight aggregate ...

· From the previous studies, it was observed that using OPBC as coarse aggregate with normal sand, ... However, it should be noted that manufacturing process of these types of LWAs is not ecological and environmental due to need of very high temperature up to about 1200 °C . To provide such a high temperature huge amount of fossil fuel is required. In addition, the cost of artificial LWAs is ...

Latest Posts

- هل تعلم أن الحصى

- تقرير عن مشروع مطحنة الفحم بيهار

- مم خام الحديد الرطب تهتز الشاشة

- معدات مخروط محطم

- النظام الحالي لمشروع كسارة الحجر

- دليل استخدام الهزاز شاكر

- نيجيريا الحجر الجيري سحق آلية محمولة صانع

- شرح جهاز الارسال المطرقة

- الهندي مصنع مخروط محطم

- غانا مصنع الذهب الرشح

- تصميم مصنع الجبس خط الانتاج

- آلة التعويم خام الزنك

- الفك محطم ، 600x 900

- مصنع الاسمنت الصانع

- Cone Kangwon Cone Crusher

- Crusher Gravel Hammers Mill Au

- Coal Mine Videos The Republic Of Congo

- Tantalite Mining Plant

- Screening Plant Operations

- How To Calculate Power Required For Chain Conveyor

- Rock Crusher Parts Georgia

- Equipment Molybdenum Process

- Grinding Machine Saleser In Colombo

- Company Jaw Crusher Dragon Nigeria Stone Crusher Machine

- Small Mini Cement Plant In Ghana

- Small Hammer Mill Plans

- Monitoring Of Mineral Processing Systems By Using Textural

- Mill Used To Pump

- Copper Ore Concentrate Manufacturers

- Minerals Grinders Manufacturers Kenya