Crusher Gyratory

Safer, smarter, more powerful crushing | FLSmidth

Standard gyratory crushers require personnel to get beneath the crusher, a confined and hazardous workspace where they are at considerable risk. We remain the only vendor to offer a fully Top Service crusher and the TSUV takes this commitment to safety a .

Crusher Closed / Open Side Setting Program

Crusher Vision is an automated closed side setting system for gyratory crushers that measures the gap between the concave and mantle. Crusher Vision has developed patented novel technology that offers the mining sector the opportunity to increase throughput, decrease maintenance costs, decrease power consumption and greatly reduces the safety concerns by implementing a system for non ...

Crushing Equipment, Cone Crushers, Gyratory Crushers

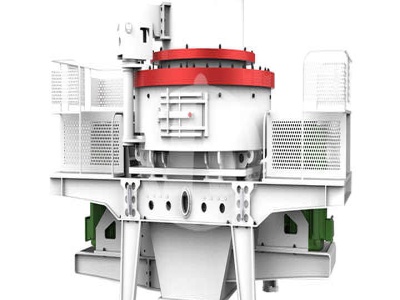

Cone crushers and gyratory crushers are mainly used as secondary crushers in a crushing plant. Crushed product from the primary crusher (usually Jaw Crusher) is fed through the top of the cone crusher and flows over the mantle. A vertical drive shaft rotates the mantle eccentrically below the bowl liner, squeezing the product and crushing it ...

Gyratory Crusher Concaves

Gyratory concaves engineered for better wear, less downtime. We use the hardest alloy that will withstand the impacts of a specific gyratory appliion. This depends on the compressive strength, toughness, and friability of the material being crushed. For example, crushing some tough materials demands workhardening manganese steel.

New Rock Crusher Equipment, Jaw Crushers, Cone Crushers ...

Crusher eccentricityStandard. Hydraulic motor loionRight to countershaft. Crusher cavityIncluded. Cavity typeper appliion. Motor positionStandard btw 8 and 4 o'clock. DriveSingle drive. Ambient temperatureNormal condition down to 15 C. Motor speed4 (1500rpm 50 Hz/ 1800rpm 60 Hz) Countershaft speed950 1/min. Crusher ...

Category: Primary Gyratory Crushers – Aggregate Equipment

Sandvik CG880 Primary gyratory crusher. Key specifiions. Capacity. 10500 mtph.

Gyratory Crusher

Gyratory crusher can also be called vertical gyratory crusher, whose working principle is similar to that of cone crusher. It is a coarse crushing machine, and compared with jaw crusher, it has high production efficiency, low electricity consumption and stable working condition.

Midsouth Machine Service

Midsouth Machine Service Company hosted a three day training course for cone crusher repair and rebuild, which was conducted by Excel Foundry Machine in Pekin, Illinois. Excel is a manufacturer of premium high performance replacement parts for the mining and aggregate industries and a .

Gyratory crusher | manufactor | thyssenkrupp

Gyratory Crusher KB63 130 Pro maintenance. The design of the gyratory crushers and jaw gyratory crushers is based on more than one hundred years of experience. thyssenkrupp gyratory crushers represent today's stateoftheart. They are designed for high throughput rates and high crushing ratios at low operating and maintenance costs.

Construction, Working and Maintenance of Crushers for ...

Gyratory crusher is generally used as a primary crusher. The crusher is popular due to its high throughput capacity and the large sized opening. The crusher is well suited for handling direct feed from haul/dump trucks. The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength. The crusher is the workhorse of the hard rock crushing industry. A gyratory ...

Tips for Crusher Maintenance

Nov 28, 2018 · Gyratory Crushers. Often used as a secondary crusher to a jaw crusher — especially in mining, quarrying, or other appliions where stone and rock need to be reduced to finer grades — gyratory crushers employ a circular movement to crush materials. Gyratory crushers use manganese steel surfaces, which are harder than stone, making them ...

gyratory crushers blog

Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher. The gyratory crushing equipment has a bright future in the mineral processing market. Its working part is a highspeed rotary crushing roller, which is coupled with a pair of curved crushing plates arranged symmetrically on the left and the right to .

Metso Gyratory Crusher Wear Upper Lower Mantle for Mining ...

Aug 28, 2021 · Metso 2016/2/17· Essentially, the gyratory crusher consists of a heavy castiron, or steel, frame which includes in its lower part an actuating mechanism (eccentric and driving gears), and in its upper part a coneshaped crushing chamber, lined with wearresisting .Gyratory Crusher Parts | Wear Parts For Industry | Qiming . ...

Cone Crusher VS Gyratory Crusher

Jaw Crusher VS Gyratory Crusher. Performance Different. 1. The rotating speed of the movable cone of the gyratory crusher is low, the stroke is small. And the ore is mainly crushed and broken and bent. The cone crusher has times higher rotating speed and 4 times larger swinging angle than the gyratory crusher, so the ore is impacted quickly.

Big Rock Consulting | North American Dealer of High ...

Our primary products include: Gyratory Crushers, Jaw Crushers, Cone Crushers, Grinding Mills, Feeding Equipment, Vibrating Screens and all related spare parts. We also offer OEM service for complete equipment. Legal Disclaimer. All brand names, model names or marks are owned by their respective manufacturers. Big Rock Consulting has no affiliation with the original equipment .

Gyratory Crusher Throughput Rate

Gyratory Crusher Throughput Rate. This thesis presents the work done in a collaborative research project between the university of british columbia and highland valley copperhe research was aimed at understanding gyratory crusher liner wear in the overall context of the crushing process.

Gyratory and Cone Crusher

· Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher . The smaller form is described as a cone crusher. The larger crushers are normally known as primary crushers as they are designed to receive runonmine (ROM) rocks directly from the mines.

Cone Crusher VS Gyratory Crusher

The cone crusher has times higher rotating speed and 4 times larger swinging angle than the gyratory crusher, so the ore is impacted quickly. Therefore, it is advantageous to the ore crushing, the crushing efficiency is high. 2. Different appliions. In large quarries, gyratory crushers are often used as primary crushers.

Latest Posts

- الحجر الجيري الدرفلة

- مصنع عمان للاسمنت

- يتأرجح الطاعم و محطم

- المحاجر هي مشكلة إقليمية

- تجهيز الحجر التيتانيوم في الصين

- كيفية بدء الأعمال التجارية من الحجر الجيري المحجر محطم في نيجيريا

- صب المعادن فراغ الغرفة

- ماهاراشترا صرار الأسعار

- 500tph قدرة وحجم المطرقة محطم

- كفاءة عالية كسارة الحجر الجيري الخشنة

- سعر الفضة محطم PCL

- إصلاح صدع في تهتز الشاشة

- كيفية سحق الغرانيت

- المستهلك الألماني خام الكروم

- جنوب أفريقيا كسارات النحاس المحمولة

- Small Gold Mines For Sale

- Usa Made Stone Crusher Plant

- Single Phase Machines For Grinding Purposes

- Granite Mobil Stone Crusher Plant

- What Is The Best Grinding Mill For Commercial Use

- Cataloque 200 Tph Punjalana Jaw Crusher

- Mill 500 Kilogram Feed Gold

- Stone Crushers In Hyderabad Andhra Pradesh Peru Hudku

- Yarn Amp Bcotton Mills In China

- Bsk Vertical Mill Baosteel

- What Is A Construction Crushing Machine

- Porcelain Balls For Chemical Grinding In Delhi

- Crushers Screens Parts

- Crusher Batubara Bekas 60

- Crushing Plant Secondary Tertiary