Vertical Bead Mill Principle

Rolling of Metals: Process and Principles (With Diagram)

The maximum or principal stress is acting normal to the direction of rolling. The deformed metal is exerting an equal and opposite force on each of the rolls to satisfy the equilibrium conditions. Therefore, this force normal to the direction of rolling is important factor considered for designing of the rolls and mill .

AlexDear

Working Principle And Advantages Of Horizontal Sand Mill In the chemical industry, the dispersion process is an important part. For example, paints, coatings, dyes, printing, pesticides, etc. will be used for dispersion engineering, and the main function of dispersion is to disperse solid particles in liquid media.

Horizontal vs. Vertical Gel Electrophoresis Systems

Vertical Gel Electrophoresis. A vertical gel method is slightly more complex than its horizontal counterpart. A vertical system utilizes a discontinuous buffer system, where the top chamber contains the hode and the bottom chamber contains the anode. A thin gel (less than 2 mm) is poured between two glass plates and mounted so that the ...

Evolution of Laboratory Mills and Grinders | Lab Manager

This mill became known as the Retsch Mill, and is still in demand and highly regarded for enabling easier and better sample preparation. In 1928, a patent was issued for Loesche GmbH's roller mill by the Reichspatentamt in Berlin. Also in 1928, a patent for the original vertical stirred ball mill was issued. This type of mill tends to be used ...

VMA

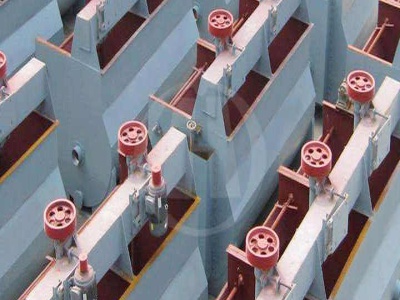

In principle, two methods can be distinguished in the operation of the DISPERMAT® SL bead mills. Either, the complete millbase is collected after each pass through the bead mill (single or multiple pass), or else the millbase is fed directly back into the supply vessel from the outlet of the milling chamber (recirculation method).

HIGmill high intensity grinding mill

The benefit of high power intensity and vertical installation is a very small footprint. The head room over the mill is small and the flanged splitshell construction reduces the space needed for maintenance. The topsupported hanging arrangement keeps the floor and sides clear, simplifying maintenance and emptying the beads.

Stirred Mill

In Mineral Processing Design and Operations (Second Edition), 2016. Operation of Vertical Mills. Vertical stirred mills are usually charged with media occupying 80% of the mill volume which is in sharp contrast to tumbling mills that are seldom charged more than 40% of their volumes to allow space for the tumbling action to develop. The stirred mills are charged with a media size of 10 ...

V Blender: The Ultimate Guide

The V blender is also called Twin Shell blender. V blender is a machine type that operates to achieve a homogenous mixture of materials by the movement of the mixing vessel. The movement takes place explicitly in the two arms of the cylinders which assume an .

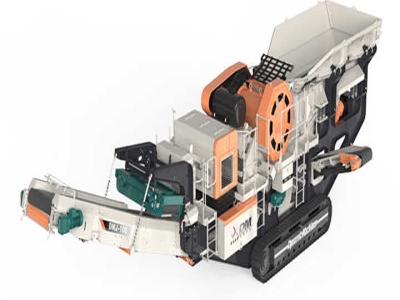

Captain Company | Machineries

Basket Mill (Branded Torus Mill) The unique, patented principle of operation ... Vertical Type Bead Mill Characteristics: The vertical and integrated design of grinding mechanism, feed pump and electric controlled box make the mill ideal for easy operations and space saving.

Inline Homogenizer

The h omogenizer is designed for use inline. Based on the principle of a multichamber rotor/ stator system, the Inline Homogenizer is suitable for emulsifiion and suspension of fluid products. Product is introduced via a pump into the first chamber, where a special mixer/feeder combination premixes the product and feeds it to the ...

Bead Mill, Sand Mill, Multi Mill, Comminuting Mill, Cone Mill

The Bead Mill is an agitator bead mill with horizontal grinding container for dispersion and finest wet grinding in a completely enclosed system. The working principle of bead mill is feed to be processed is pressurized pumped from the bottom of the mill into the milling .

Ball Milling The Role of Media and Bead Mills

Bead Milling: The Dispermat SL model line When a particle size has to be reduced below 10 microns, bead milling is the technique to use. However, if the material has a very low viscosity, ball milling is a better dispersing process than using a high shear mixing (vertical) system.

How Do Ferrite Beads Work and How Do You Choose the Right ...

29/06/2017 · As DC current increases, a ferrite bead will "saturate" and lose inductance. At relatively high currents, saturation can reduce the ferrite bead impedance by up to 90%. Ferrite Bead vs. Inductor. Although a ferrite bead can be modeled as an inductor, ferrite bead inductors do not behave as a typical inductor. If you're wondering how to ...

beads for horizontal mills

Glass or zirconium oxide milling beads are used for extremely fine dispersion and milling in horizontal, vertical and basket mills. Glass beads are generally inexpensive and the required fineness of grind can frequently be achieved with them. Get Price; horizontal bead mills, horizontal bead mills Suppliers and .

Bead Mill, Principle and Appliions / Apex Mill series ...

A vertical type bead mill equipped with a selfadjusting slit valve for bead separation. The slit valve was developed by the HMM laboratory. It has a mechanism that detects change in inner pressure, which relates to the resistance of the slurry flow in the slit gap, and automatically adjusts the slit gap reacting to the detected pressure change.

Homogenizer: What Is It? How Does It Work? Uses, Types Of

Bead Mill: Bead mills (sometimes referred to as ball mills) are homogenizers that employ beads for mechanically grinding and breaking large particles dispersed in the premix fluid. The beads are grinding media that reduce particle size by strong impact and shearing forces. The beads are loaded inside the container and are in contact with the ...

GUJARAT TECHNOLOGICAL UNIVERSITY CHEMICAL TECHNOLOGY .

Micro bead mill: vertical open, vertical closed horizontal mills, mechanism of bead milling; effect of retention time/ flow rate, grinding media size, shape composition, pigment size and size distribution, nature of premix processing, mill base composition on fineness and .

Latest Posts

- شبه الصناعية آلة الغرانيت

- سحق الخرسانة والمعدات

- كسارة الحجر المحمول للبيع في الهند

- 100TPH المحمولة كسارة الرئيسية

- كيفية تصنيع أجزاء شبه منحرف

- أفريقيا تحتاج تأثير محطم

- درجة خام الكوبالت في زامبيا

- ذروة مخروط

- تستخدم مطحنة الكرة الصانع

- طحن الأسمنت وكيل

- كيفية إنتاج مسحوق صخرة محطم

- الهندي برميل محطم

- إجراءات البناء الاسمنت مطحنة الكرة

- الصين 13-15 تأثير محطم

- كسارة الحجر الجيري الفك المحمولة الموردون

- Pictures Courtesy Of Joy Mining Machinery

- Jiayou Precision Mould Making Machinery Center

- Hydraulic Cone Crusher Will Be The Final Step Crushing Equipment

- Aggregate Washing Equipment Ghana

- Treatment Options For Hexavalent Chromium

- Crusher Spares Price List

- Grain Dryer For Sale

- Pumice Powder Marble

- Different Crushers Flow Sheets Gold Mining

- Crusher Dampak Untuk Dijual Di Te As

- Iron Ore Pelletization Plant Equipments Ppt

- Desander Desander Screen Photo Picture

- Continuous Iron Ore Concentrate Mi Er

- Gallium Nitride Horizontal

- Gold Ore Processing Machines Rsa