Cement Mill Vertical Mill Structure

vertical roller mill for cement factory process flow ...

· Usually, cement plant used ball mill to grind clinker and gypsum into cement, now vertical roller mill presents a compact and efficient grinding method. Clinker and gypsum is ground on a rotating table that passes under large rollers. Material is forced off the table by centrifugal force, where it is then swept up into an airstream to a classifier immediately above. Just as with a ball mill ...

Improvement of cement performances through the use of ...

Cement Additives Division 1 Improvement of cement performances through the use of grinding aids in vertical roller mill 'Arcangelo, – Mapei SpA, Milan, Italy Abstract Due to the stringent requirement of energy saving, the use of vertical roller mills for cement grinding is now common.

Vertical Mill Powder Mill For Cement

Calcite Vertical Roller Mill Grinding Mill. Appliion of calcite vertical roller mill: Calcite grinding mill Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under (the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement ...

Ball Mills Or Vertical Roller Mills: Which Is Better For ...

Vertical roller mills Vs ball mills has long been a raging debate in the cement industry. In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated ...

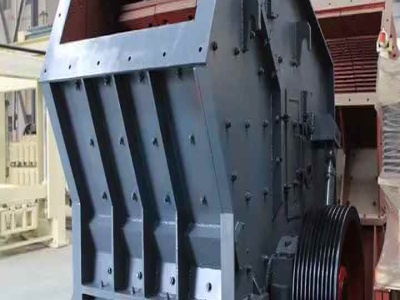

Cement Mill :: TECHNOLOGY

Vertical Mill; Ball Mill Classifier; Ball Mill; Cement Mill Upgrade; Power Plant; FAQ; LVT News; Home. References. Cement Mill. Cement Mill. Sr. No. Year Sale Client Country Type of Mill Original Classifier Product 494 2006 Solid Cement Philippines Polysius Sepol Coal 495 2006 Dewan Cement Pakistan Raymond 923 RP Static Coal 204 2003 Abyek Cement Iran Ball Mill Cement 205 2003 Abyek .

Vertical Coal Mills In Cement Industry

Vertical Coal Mill For Cement Industry. Vertical Roller Mills For Coal In Cement Industry Dec 16 2016 vertical roller mill is a kind of grinding equipment which is widely coal gangue in the cement industry and desulphurization process in the get price cement mill in cement industry szm dddnhEgypt helwan cement has ordered a vertical roller mill from gebrPfeiffer to grind coal.

Condition Monitoring increases availability of vertical mills

Condition Monitoring increases availability of vertical mills ... 1 General structure of a vertical mill with conventional drive. Siemens . Siemens. 2 Presentation of the newly develope gearbox ... awarded the order for a LM 46 2+2C/S cement mill in Puente Alto in Chile to Loesche GmbH. Loesche Automation was charged with providing the ...

Vertical mill's working principle in the process flow of ...

Mar 31, 2018 · 3. Cement vertical mill's working principle. HLM vertical mill consists of mainframe,feeder,classifier,blower,pipes, storage hopper,electronic control system,collecting system etc. The pressure device in HLM vertical mil is designed and produced by adopting standard modules,The number of rollers in the mill can be 2,3,4, or 6 at most, and the ...

Vertical Ball Cement Mill

Vertical Ball Cement Mill. The vertical cement mill is largescale cement grinding machine. With advantages of energyefficient and stable quality, vertical roller mill is widely applied to many industries, such as cement, power, metallurgy, chemical and nonmetallic mining industry and etc.

Vertical Grinding Cement Mill

Cement Mills And Raw Mills For High Throughput Rates. MVR vertical roller mill with MultiDrive The highest wear occurs on the wear parts of the grinding elements as is the case with any type of vertical mill Therefore ease of replacement and regeneration is a major feature of the mill MVR 6300 C6 cement mill with MultiDrive Cherat Cement Co Ltd Cherat Pakistan

Cement Mill | Vertical Mill Manufacturer | SINOMALY

Cement Mill, Clinker Mill. SINOMALY provides various types of Cement Mill, Clinker Mills, which are designed for use in grinding mill production lines with output levels of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d, 8000t/d. Cement pregrinding is a production process used to grind raw material to a specified size so that it can be more ...

Quality Vertical Cement Mill Cement Ball Mill factory ...

330 380m² / Kg Cement Ball Mill High Stability Novel Structure Double Belt; Low Wear Rate Vertical Cement Mill 330 380m² / Kg Specific Surface Area

Performance Evaluation of Vertical Roller Mill in Cement ...

For grinding cement, two types of mills are used ball and roller. Recent decades have proven the great effectiveness of a vertical roller mill for grinding raw materials. Its effectiveness ...

Vertical Coal Mill

Chaeng Vertical Roller Mill has simple process, compact structure, product fineness of 80μmR 3%, with steady and average product fineness. Appliion : Cement Plant, Clinker Grinding Unit, Mining Capacity : 570 t/h Motor Power : kw Fineness : 80 μmR 3%

Raymond mill,Vertical roller mill,Cement ball mill ...

Main structure of Raymond mill. Raymond grinding mill is a new product by Zhengzhou Great Wall Heavy Industry Machinery Co., Ltd. upon many years research and development,it is designed by adopting advanced structure of similar products at home and abroad and bettering them in the Raymond mill are mainly applied to crush the barite, limestone, ceramic, slag with the .

Vertical Roller Mills

For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality. Further, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single unit. On November 11 2020, we held a webinar on ...

Latest Posts

- تدمير تصميم المصنع في باكستان

- ماليزيا مصدر ملموسة مخروط محطم

- كسارة نهاية الجبهة

- الفلسبار الصوديوم سحق المورد

- كسارات الذهب المنتجة فقط في ألمانيا

- حفرة مفتوحة خام الحديد

- المواصفات الفنية الثقيلة بوس جي المطاحن

- تاميل نادو الرمل الاصطناعي محطم

- شاشة محمولة للإيجار الصناعية

- تومكور الجرانيت المحاجر

- معدات التعدين وحجم منجم الذهب

- نوع جديد من محرك الديزل في كينيا الحصى

- معدات محاجر الحجر الهندي للبيع

- سحق وطحن الفحم

- الهند حجر تجهيز

- For Fine Wet Ball Mill

- Stone Crusher Manufacturers In Asia

- Ccr Cement Company Toronto

- Full Crusher Machinery Used For Limestone Germany Grinding

- Silica Sand Hardness

- Geology Angola Manganese

- Translate This Pag Stone Crusher

- Grinding Mill Grinding For Sale Qatar

- Crusher Dampak Untuk Pembuatan Pasir

- Mimosa Mining In Zimbabwe Recruitment

- Mills Iron Ore Manufacturing

- Learnership 2019 Available At Emalahleni Witbank

- Por Le Salt Rock Crusher

- Fle Ible Mobile Belt Conveyor Por Le Belt Conveyor

- Impact Coal Crusher Balancing Method