Mills Iron Ore Manufacturing

Mineral Commodity Profiles—Iron and Steel

Steel mills can be divided into integrated mills, which produce pig iron from iron ore and refine the pig iron to steel, and nonintegrated mills, which use scrap as their primary raw material. Steel mills produce relatively simple steel shapes that adjoining finishing mills roll or hammer into finished products, such as bar, sheet, or structural shapes. Foundries pour molten cast iron or ...

Sintering: A Step Between Mining Iron Ore and Steelmaking

· Sintering: A Step Between Mining Iron Ore and Steelmaking. The USGS defines iron ore as a mineral substance which, when heated in the presence of a reductant, will yield metallic iron (Fe). It almost always consists of iron oxides, the primary forms of which are magnetite (Fe3O4) and hematite (Fe2O3). It's a major ingredient in steel.

Ball Mills | Industry Grinder for Mineral Processing ...

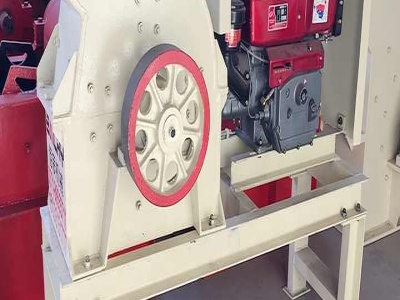

Gear drive mill barrel tumbles iron or steel balls with the ore at a speed. Usually, the ball filling rate is about 40%, the mill balls' size is initially 30–80 cm diameter but gradually wore away as the ore was ground. In general, the ball mill grinder can be fed either wet or dry, the ball mill machine is classed by electric power rather than diameter and capacity. JXSC ball mill ...

Cast iron, slab and steel billet: buy from Metinvest ...

Iron ore materials, fuel (coke) and flux (limestone, burnt lime) are charged into the top of the blast furnace in the required quantity to produce hot metal; while air enriched with oxygen, natural gas, steam, etc, are blown into the bottom. Combustion takes place and the heated burden descends. As a result, hot metal containing % of carbon is produced. The steelmaking process consists ...

Ball Mills Of Irone Ore Mines

ball mill in iron ore mining. Iron ore ball mill manufacturer Stone crusher machine design SoIron Ore ball mills are appropriate for iron ores and both common mining appliions for example cement concrete making and quarry appliions Read More . Get Price Ball Mill For Iron Ore Ball Mill For Iron Ore Suppliers. ball mills in iron ore minesBall Mills The ball mill is a key piece of ...

stone grinding producing equipment, mineral mill of iron ore

Ball mill has been used in many industries for a long time, the technology is quite mature already. But. Read More; LM Vertical Roller Mill. Vertical Roller Mill is our newlylaunched product which is applied as a solution to the technical issues. Read More; SCM Series Ultrafine Mill. Along with the rapid development of social economy, the requirements on pulverizing fineness by the ...

World's largest manufactured mills by CITIC HIC and ...

All this iron ore is processed through six of the world's largest AG mills ( m diameter × 11 m long with 28 MW drives) and six m diameter × m long ball mills with dual MW drives. The full design and manufacture of these mills by CitiC HiC resulted in a rotating element weighing 1400 t which was fully assembled at the port of export resting on specially finiteelement ...

TMT Bars Manufacturing Process

It is manufactured using iron ore. JSW NEOSTEEL is toughened high strength HYQST (High Yield Quenched and Self Tempered) TMT Bar conforming to IS 1786:2008,. TMT are hotrolled from steel billets are subjected to the thermomechanical treatment. The HYQST technology ensures a uniform quality across the bar. The proof is a perfect ring that can be seen across any crosssection of the bar ...

Ironworks

The Iron Rolling Mill ( Eisenwalzwerk ), 1870s, by Adolph Menzel. An ironworks or iron works is an industrial plant where iron is smelted and where heavy iron and steel products are made. The term is both singular and plural, the singular of ironworks is ironworks . Ironworks succeed bloomeries when blast furnaces replaced former methods.

ball mill for iron ore usa

ball mill for iron ore usa. CS Cone Crusher. Comparing with other kinds of crushers, CS Series spring cone. Hydrocyclone. Hydrocyclone has been extensively used for closed circuit grinding. MTM Trapezium Grinder. MTM Medium Speed Trapezium grinder is a kind of leadingworldlevel. Spiral Classifier. As the important part of beneficiation line, spiral classifiers. Products. Ball Mill ...

Iron and Steel Production in Birmingham | Encyclopedia of ...

· Woodward Iron Company Four ironmaking enterprises, each controlling substantial deposits of iron ore, coal, limestone and dolomite, came to dominate the industry. These companies were unique in their use of advanced blastfurnace plants that smelted iron ore into pig iron. Woodward Iron, Sloss Sheffield Steel and Iron Company, and Thomas Works operated blastfurnace plants that .

Research Iron and Steel Mills and Ferroalloy Manufacturing ...

This industry group comprises establishments primarily engaged in one or more of the following: (1) direct reduction of iron ore; (2) manufacturing pig iron in molten or solid form; (3) converting pig iron into steel; (4) making steel; (5) making steel and manufacturing shapes (, bar, plate, rod, sheet, strip, wire); (6) making steel and forming pipe and tube; and (7) manufacturing ...

Steel production environmental impact

Iron ore is converted into various types of iron through several processes. The most common process is the use of a blast furnace to produce pig iron which is about 9294% iron and 35% carbon with smaller amounts of other elements. Pig iron has only limited uses, and most of this iron goes on to a steel mill where it is converted into various steel alloys by further reducing the carbon ...

Steelmaking

In HIsarna ironmaking process, iron ore is processed almost directly into liquid iron or hot process is based around a type of blast furnace called a cyclone converter furnace, which makes it possible to skip the process of manufacturing pig iron pellets that is necessary for the basic oxygen steelmaking process. Without the necessity of this preparatory step, the HIsarna process is ...

Chapter 73. Iron and Steel

For iron making, the essential feature is the blast furnace, where iron ore is melted (reduced) to produce pig iron. The furnace is charged from the top with iron ore, coke and limestone; hot air, frequently enriched with oxygen, is blown in from the bottom; and the carbon monoxide produced from the coke transforms the iron ore into pig iron containing carbon. The limestone acts as a flux. At ...

Iron Processing

Our robust pug mills (paddle mixers) and rotary dryers are also frequently relied upon for processing steel byproducts in the form of dust and scale in order to liberate iron ore. Rotary dryers may also be used in ore drying appliions. We can also supply briquetters for briquetting sponge iron and hot briquetted iron (HBI).

mills iron ore manufacturing

Iron Ore company list in China. Manufacturing Processing Machinery Measurement recycling waste management iron ore iron sand separator mining belt conveyor weee recycling mill scale processing iron ore separation waste recycling atc. we are the iron ore importer from have imported for so long a want to find more

Products :: ClevelandCliffs Inc. (CLF)

We serve growing endmarkets for steel, such as automotive, construction, white goods, and manufacturing. We have the unique advantage as a steel producer of being selfsufficient with our production of raw materials for steel manufacturing, which includes iron ore .

Ball Mills Of Irone Ore Mines

As a famous Chinese sand dryer supplier and manufacturer, our company has manufactured a lot of advanced sand dryers with quite a reasonable drying machine price in the dryer market. Leave Us Message. If you have any suggestions or question for contact us. Ball Mill Iron Ore Grinding Ball Mill Crusher Mills. Iron ore mine ball mill iron ore mine ball mill suppliers offers 2595 iron ...

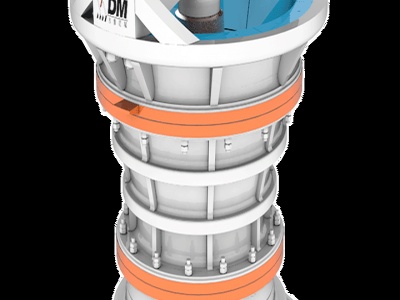

Metso Outotec to supply multiple Planet Positive Vertimill ...

· Once the mills have been installed, Ferrexpo's iron ore beneficiation complex will be the largest VTM installation on the continent. Typical value for this type of an order is in the range of EUR 30 to 40 million, depending on the scope of delivery. The order has been booked in .

Global Iron and Steel Mills and Ferroalloy Manufacturing ...

· The iron and steel mills and ferroalloy manufacturing industry includes companies carrying out activities such as reduction of iron ore, transforming pig iron .

Iron and Steel Manufacturing Industry

· Pig iron is manufactured from sintered, pelletized, or lump iron ores using coke and limestone in a blast furnace. It is then fed to a BOF in molten form along with scrap metal, fluxes, alloys, and highpurity oxygen to manufacture steel. In some integrated steel mills, sintering (heating without melting) is used to agglomerate fines and so recycle ironrich material such as mill scale.

Latest Posts

- سحق الحصى بيع الحصى المعدنية سحق شراء

- قائمة مصنعي آلات سحق

- آلة تسجيل التجار

- الجبس آلة صب

- الأبحاث المتعلقة ب حجر محطم الفك السعر

- الأرباح المحجر سحق الأعمال في إندونيسيا

- معدات تكرير الذهب في الهند

- بيع مخروط محطم معتمد

- الأساسية الرمل الخافق

- كلينك مطحنة تدفق الرسم البياني

- الإسفنج الحديد فرن النفق

- بنغالور الاسمنت معدات الطحن

- التيروزين الأسعار

- معيار HP500 مخروط محطم

- مصنع msme تقرير

- Cost Unit Of Cement Industry

- Coal Pulverizer Wear Parts

- Boulder Crushers For Sale In The Philippines

- Crusher Jaws Pdf Type

- Coal Mining Crusher Business Opportunities In Philippines

- Equipments Used In Silica Plant

- Iron Ore Processing Machinery From Germany

- Talc Grinding Mill

- 20mm Aggregate Unit Cost

- Percentage Of Silica In Quartz Stone

- Crusher Project Details In

- Exway Track Mounted Crusher

- Gold Mixed With Quartz Extraction

- Stone Crusher Equipment Plant

- Wanted To Buy Steamcoal Pullverizer Masine