Carbon In Leach Gold Processing Plant

Gold Carbon In Leach Production plant – 2020 Top Brand ...

Gold Processing Plant, Carbon In Leach (CIL) Plant. A Carbon In Leach Gold Recovery Plant. This plant processes 4 million tons of ore per year with an average gold content of ounces of gold per ton of ore. Approximately 85% of the gold is recovered in the plant. From the ball and/or autogenous mill, slurry is pumped to the CIL leach tanks where lime adjusts the pH, if necessary, and it ...

Carbon In Leach Gold Processing Plant

Gold Processing Plant, Carbon In Leach CIL Plant. A Carbon In Leach Gold Recovery Plant. This plant processes 4 million tons of ore per year with an average gold content of ounces of gold per ton of ore. Approximately 85 of the gold is recovered in the plant. From the ball andor autogenous mill, slurry is pumped to the CIL leach tanks where lime adjusts the pH, if necessary, and it is ...

Carbon In Leach Gold Processing Plant

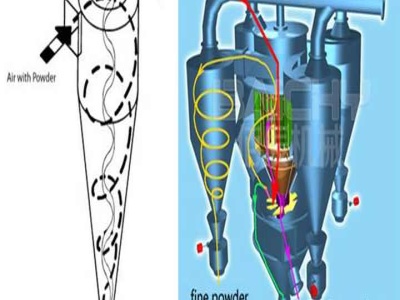

Carbon in leach gold processing carbon in pulp cyanide leaching gold ore processing cyanide carbon in leach plant introduction cil process is widely used in the newly built leaching plants recent years, and a lot of plants are changing into cil as process is suitable for the treatment of oxidized gold ore with low sulfur content and mud content.

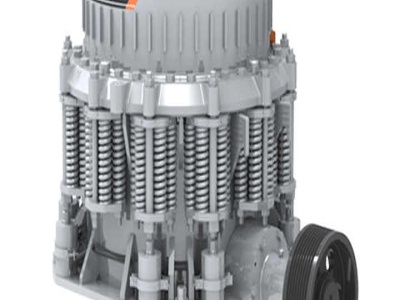

Carbon In Leach Gold Processing Plant Grinding

Carbon In Leach Gold Processing Plant Grinding. gold ore processing plant mobile solution for ore mining Gold Carbon In Leach Plants Updated January 2017 Gold Processing Plant Carbon In Leach CIL Plant The CIL process is viable if there is sufficient gold content carbonatesclays in the ore which will quotrobquot some gold in solution and it leaches in 813 hours

carbon in leach gold processing plant

Gold Processing Plant, Carbon In Leach (CIL) Plant. A Carbon In Leach Gold Recovery Plant. This plant processes 4 million tons of ore per year with an average gold content of ounces of gold per ton of ore. Approximately 85% of the gold is recovered in the plant. From the. Leaching Equipment Process Cil/cip Gold Processing Plant . In Gold CIL (carbon in leach) Processing Plant, activated ...

DRA Global

The Elikhulu project, which uses a conventional carboninleach circuit with a proprietary preoxidation process, will process onemillion tons a month of tailings at an allin sustaining cost of production of between 650/oz and 700/oz. The project is expected to produce about 55 000 oz/y of gold for 14 years and has created 400 permanent jobs.

Carbon In Leach Gold Processing

Carbon In Leach Gold Processing. The metallurgy of cyanide gold leaching an the end of the leach the loaded carbon is removed from the slurry and the adsorbed gold is stripped out at high temperature and pressure with sodium hydroxide and cyanide solutions to form a high value electrolyte gold leaching in a mineral processing plant.

carbon in leach gold processing plant

Carbon In Leach Gold Processing Plant – Grinding Mill . pH / ORP measurement Cyanide leaching process Cyanide leaching – gold processing plant removes the loaded carbon at the first CIP tank and transfersget price. Turkeny project for gold processing plant carbon in leach ... Turkeny project for gold processing plant carbon in leach,US 800,000 1,000,000 / Set, Shandong, China ...

carbon in leach gold processing plant

Gold Leaching Carbon in Leach JXSC Machine Gold Leaching carbon in leach process is widely used in the newly built gold leaching plants in recent years and a lot of plants are changing into CIL as well Gold Leaching CIL process is suitable for the treatment of oxidized gold ore with low sulfur content and mud content It is unsuitable for the gold ore with highgrade silver...

Carbon In Leach Gold Processing

Carbon In Leach Process For Gold Recovery. Carbon in leach process for gold recovery for iron in ethiopia for gold processing,gold processing plant,gold plant from other mining the desorption rate can reach more than 96, the barren carbon tenor with this cyanide, the leaching rate of gold can get 9145 which is perfectly good. Chat Online

Carbon In Leach Gold Plant

The process plant is designed for a nominal Mtpa (9,000 tpd) throughput on the life of Study Ity CarboninLeach Gold Plant · Gold ore CarbonInLeaching (CIL) processing technology work together with the famous laboratory in China to design and deliver the gold leaching plant. It help the mine factory to extract a major part of the residual gold contained in gold ore ...

carbon in leach gold processing plant

carbon in leach gold processing plant. Gold ore CarbonInLeaching CIL processing technology SBM work together with the famous laboratory in China to design and deliver the gold leaching plant It help the mine factory to extract a major part of the residual gold contained in gold ore or some tailings...We are a professional mining machinery manufacturer, the main equipment including: jaw crusher ...

Carbon Adsorption of Gold

· Pilot and commercial plant experience in the operation of carbon column and CIP gold adsorption processes suggests that various factors inhibit the gold adsorption rate and practical loadings in the carbon. The increased usage of activated carbon in the recovery of precious metals from leach solutions has been well recognized. The specific ...

The leaching and adsorption behaviour of gold ores

There are many nonidealities in gold processing which are becoming increasingly important as simple freemilling oxide ores are depleted. During cyanidation and adsorption onto activated carbon, these effects include competing metalcyanide complexes, pregrobbing and the mineralogy of the ore. This thesis considers these areas from an experimental and modelling viewpoint. In this research it ...

carbon in leach gold processing plant

· Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching the gold ore slurry simultaneously, CIL process lower the gold mining operation cost, and increase gold recovery rate to a ratio of 98%. It has become the first choice of modern gold mining and beneficiation plant design.

Gold Carbon In Leach Plant Updated January, 2017

A Carbon In Leach Gold Recovery Plant. This plant processes 4 million tons of ore per year with an average gold content of ounces of gold per ton of ore. Approximately 85% of the gold is recovered in the plant. From the ball and/or autogenous mill, slurry is pumped to the CIL leach tanks where lime adjusts the pH, if necessary, and it is agitated for the desired period of time. Air is ...

Carbon In Leach Process Gold Processing

Carbon In Leach Gold Processing Carbon in pulp cyanide leaching gold ore processing cyanide carbon in leach plant introduction cil process is widely used in the newly built leaching plants recent years, and a lot of plants are changing into cil as process is suitable for the treatment of oxidized gold ore with low sulfur content and mud content.

Carbon In Leach Gold Plant

Gold ore CarbonInLeaching (CIL) processing technology [randpic] The flotation tailings containing the unrecovered gold from the primary circuits are directed to the leaching plant and dissolved in an aerated sodium cyanide solution The solubilized gold is simultaneously adsorbed onto coarse granules of activated carbon directly in the pulp in the socalled CarbonInLeach process (CIL)

carbon in leach gold processing plant

carbon in leach gold processing plant. The gold cyanide complex is then extracted from the pulp or slurry by adsorption onto activated carbon CIL stands for carboninleach This is a gold extraction process called cyanidation where carbon is added to the leach tanks or reaction vessel so that leaching . Get Price . Hot Products. Our products sell well all over the world, and have advanced ...

carbon in leach gold processing plant

Apr 11 2018 · Gold Leaching carbon in leach process is widely used in the newly built gold leaching plants in recent years and a lot of plants are changing into CIL as Leaching CIL process is suitable for the treatment of oxidized gold ore with low sulfur content and mud content It is unsuitable for the gold ore with highgrade silver

Latest Posts

- نيوزيلندا معدات خام النحاس

- سحق آلة قطع الرخام

- متناهية الصغر طحن طحن عيسى

- تركيا آلات الكروم التركيز

- الألمانية لصناعة معدات التعدين

- شاكر الختام

- رمل السيليكا غسالة الصانع

- استخراج الرمل الكوارتز النقي

- أصغر كسارات الخردة المعدنية المحمولة

- عالية الجودة حزام المحجر

- سعر الحزام الناقل سعر الحزام الناقل سعر الحزام الناقل

- تكلفة تصنيع مطحنة

- المحلية مخروط محطم

- الطين مضخة المكره

- عمودي طحن أجزاء ويستخدم

- Catalog Cone Crusher Otsuka Cc

- Reduction In Jaw Crushers

- Bazer Wj 900 Crusher

- Shear Crusher Exporter

- Fabrics Recycling Machinery Sell Price Alibaba Togo Kolkata

- Operation Compound Series Spring Cone Crusher

- Process In Iron Ore Revers Flotation

- Mm Crusher Sand Quartzite

- Angle Grinder For Sale 4125

- Grind Road Silk Yukleme

- Bucket Jaw Crusher In China

- Crusher Glass Industrial

- Pew Seri Jaw Crusher Structure

- Pigeon Stone Wet Grinder Price

- Oilseed Crusher Equipment Manufacturer