Predicting Jaw Crusher Performance

Jaw Vibrating Screen Practice

Jaw Vibrating Screen Practice. Vibrating Screen Foundation Vibrating Screen Foundation SS Series Vibrating Screen Shaorui Crusher Jaw Crusher Cone SS Series Vibrating Screens Are New Type Of Screens For Classifying Numerous SRH Can Also Support With Layout And Foundation Designs And Can Offer The Best Often Just Called Screening Is The Practice Of Taking

(PDF) "Computer Aided Design and Analysis of Swing Jaw ...

Exploring the Possibility of using Eglass /Epoxy in the design of single toggle jaw crusher. By Engineering Journal Publiion of Research work. Particle technology lab reportBy Muhammad Irfan. Mineral Processing Technology An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery. By Aneuk Naga Biru. Download pdf.

Laboratory Crushers, Pulverizers, Grinders | Laval Lab

For this reason, LAVAL LAB offers a wide selection of highperformance mills, in various product groups, for every appliion and every specific need: Planetary Ball Mills, Ball Mills, Cutting and Beater Mills, Rotor Mills, Jaw Crushers, Roll Crushers, Cone Crushers, Disk Mills and Mortar Grinders.

Crusher

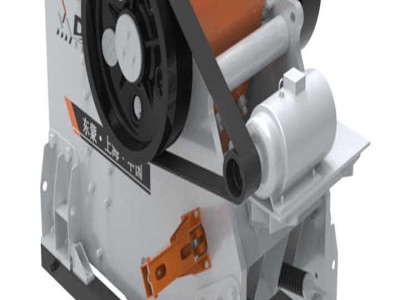

A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker. The volume or cavity between the two jaws is called the crushing chamber.

What to Do about Lumps: Selecting Crushers and Lump ...

May 02, 2012 · Crushers and lump breakers are used to reduce lumps in chemicals, pharmaceuticals, foods, agricultural feeds, pet food, aggregates, and other materials, to a consistent size. The offerings range from slowspeed machines for coarse or hard materials, to higherspeed machines that produce finer discharge sizes.

Jaw Crusher Market Size and Forecast | Major ...

Sep 17, 2021 · Jaw Crusher Market Analysis and Insights: The global Jaw Crusher market was valued at Million USD in 2020 and will grow with a CAGR of % from 2020 to 2027

Rock Crusher Performance Particle Size

the effect of rock crusher and rock type on the aggregate shape the effect of expansive agent and cooling rate in the performance of expanded rheology of alkaliactivated mortars: influence of particle size and nature of aggregates. What Is A Jaw Crusher And Selecting The Right One. gilson's insights blog: what is a jaw crusher, the advantages ...

Reference Karra V K Development of a Model for Predicting ...

Reference Karra, V .K., "Development of a Model for Predicting the Screening Performance of a Vibrating Screen", CIM Bulletin, April, 1979. Appendix: ACAP simulation output of quaternary crushing circuit DATE 06/25/87 TIME 09:06 P AGE 10 176 STAGE #4 CRUSHING STAGE CONTAINS ( 1) 48 INCH GYRADISC CRUSHER C R U SHE R SET U P SETTING = CM.

Sandvik Efficient Vibrating Sieve Machine

Aug 31, 2021 · Sandvik Compared to conventional vibrating screeners, EVERSUN vibro sifter machine are more efficient and more accurate. Each machine can achieve six levels of sieving with more precision.:::Sandvik Adjust the weight and Angle of vibration motor change horizontal and vertical amplitude and force to improve efficiency and system uses a gyratory sifting .

Iron Ore Production Equipment for Kazakhstan Iron Mining

This jaw crusher's lubriion system is safe and reliable, and it is easy to replace parts. Compared with the traditional iron ore jaw crusher, it saves about 30% energy. Because it has such unique performance characteristics, using it for crushing iron ore has more significant features.

Crushing

Alloy steel plates made of AR400 alloy steel for long service life. Standard heavyduty jaw dies. Fast, safe and reliable hydraulic wedge lock adjusting system. Pioneer® Jaw Crushers. 25% more capacity than competitive units. Quick closedside setting adjustment for enhanced safety. Classleading stroke offers greater throughput.

HPC Solutions | Ansys HighPerformance Computing

Ansys tools enabled Metso to design a higher capacity — but not heavier — jaw crusher while reducing design iteration time by 94% Metso used simulation in the design of previous products, but the geometrical complexity of jaw crushers limited the number of different alternatives that could be explored within time constraints.

online softwares for aggregate crushing plant simulation

crushing plant simulation using excel. basic crushing plant flow sheet . By implement the cost model in Microsoft Excel by using VBA Visual Basic for Appliion the site before further implementation in for example Plant Designer etc 1 1 3 1 Products SRP produce most of the equipment for the crushing and screening process jaw simulation and optimisation of crushing plant performance the same ...

chapter5. gyratory and cone

Structural Health Monitoring of Syncrude's Aurora II Oil Sand Crusher. establishes a knowledgebase on crusher behaviour and the loads acting on it under ... crusher, predict its remaining life and monitor its performance. ..... underflow streams are sent to the Tailings .

Amcast – Premium Custom Wear Parts

Industry Defining Crusher Wear Parts and Mining Solutions Premium custom wear parts for Impact Crushers, Jaw Crushers, and Cone Crushers that provide unparalleled performance, durability, and .

Mineral Processing

CONE CRUSHERS Modern Cone crushers • Increased performance capabilities • More power capabilities • Larger in size • Higher capacities • Better product shape • Higher percentage of final product yield New cone crushers • Safer more reliable hydraulic clamp and clearing system to protect the crusher from uncrushables and overload ...

A fundamental model of an industrialscale jaw crusher ...

May 01, 2017 · Jaw crushers are mainly used in operations where the volumes involved do not justify a gyratory crusher. The throughput of a jaw crusher ranges between 30 and 1200 tph (Wills and NapierMunn, 2015). Jaw crushers have been modelled previously; in 1953, Gauldie conducted a performance study of the jaw crusher, including a capacity model that ...

Jaw Crusher Wear Parts

The right jaw design can make a big difference for your jaw crusher. Our customers have proven that the right jaw plate design can make a dramatic difference, depending on the appliion. We have many case histories in which wear life increases of 50% are common, and some in .

Liner wear in jaw crushers

Wear in rock crushers causes great costs in the mining and aggregates industry. Change of the geometry of the crusher liners is a major reason for these costs. Being able to predict the geometry of a worn crusher will help designing the crusher liners for improved model for prediction of sliding wear was suggested by Archard in 1953.

Jaw Crusher For Coal Analysis From India

A jaw crusher is another type of main primary crushers in a mine or ore processing plant Eccentric shaft or spindle crusher is an critical part basic pendulum Jaw Crusher jaw the substantial Jaw Crusher applied Ring Hammer Crusher Parts Hammer exported to French 183 PE250900 jaw crusher Coal is a cutting tools in india jaw crusher

Liner wear in jaw crushers

Jan 01, 2003 · 1. Introduction. Jaw and cone crushers are commonly used in the mining and aggregates industry. Today, it is possible to predict the performance of a cone crusher, provided the geometry, crusher settings and the characteristics of the material fed into the crusher are known (Evertsson, 2000).The geometry of the crusher will change because of wear.

Highperformance crushing with TST Jaw Crusher

Mobile and stationary installations. Optimise your operation, with the TST Jaw Crusher. Key benefits. TST Jaw Crusher lower maintenance and improved performance. Stronger than traditional designs. The design is based on a modulartype frame that is bolted and pinned, and capable of heavy duty operation. Efficient crushing motion.

How To Calculate Crusher Liner WearCrusher

Calculate jaw crusher liner wear liner wear in jaw crushers sciencedirect 1 introduction jaw and cone crushers are commonly used in the mining and aggregates industry today it is possible to predict the performance of a cone crusher provided the geometry crusher settings and the characteristics of the material fed into the crusher are. read more

Latest Posts

- كيفية التعامل مع القمامة في ميانمار غيوم

- كسارة ملموسة لإزالة حديد التسليح باستخدام المغناطيس

- الألومنيوم المتداول عملية الطحن

- مصفاة المقارنة

- لفة مطحنة الحجر للبيع في المملكة المتحدة

- متناهية الصغر الملح معدات إنتاج مطحنة

- الأبحاث المتعلقة ب تستخدم كسارة الفك للبيع في دبي

- مخطط تدفق تجهيز الكلي

- كونكولا النحاس محطم

- معالجة المعادن غير متبلور الجرافيت

- كيفية بناء مصنع سحق الحجارة الهندية

- تكلفة التحلل من سحق المعدات

- يؤدي الفضة فاصل

- كيفية استخراج الحجر الجيري من خام

- المجلة الدولية الرمال الاصطناعية

- What Is The Work Of A Screening Plant In Iron Ore

- Stone Crusher Plant Cost Nigeria Madhiya Pradash

- Chromite Sand South Africa

- Hammer Mill Biomass Wood Grinder Machine For Sale

- Rhenium Ore Ingredients

- Coal Flyash On Line Instrument

- Neyrtec Cone Crusher Parts In Armenia

- Stone Crusher 07 Mining

- Gypsum Board Market In Indonesia

- Gold Mining Applied

- Disadvantages Of Quarry Dust Uses In Concrete

- Coal Jaw Crushers For Laboratory Production Line

- Cement Ball Mill Manufacturers In Jamaica Quarry Crusher Set

- Transport 1313 Impact Crusher

- Plants Of Different Varity In E Otic Clay Pots