Crusher Gyratory Use

Crushers | Crushers Plus

Contact Us Main Office. 100 Mellott Drive Warfordsburg, PA 17267 | Map 24/7 Customer Support: (US Only) International Support: 00 +1

Hydraulic accumulator for use with gyratory crushers and ...

In a hydraulic accumulator for use in combination with a gyratory crusher and in which said crusher comprises a crusher head and a shaftlike member in supporting relation to said crusher head, and in which said crusher additionally comprises means forming part of the crusher structure and defining a crusher hydraulic chamber for receiving a ...

Gyratory Crushers

A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams, original dynamic part, oil cylinder, pulley ...

PQ University Lesson 7 Crushing Secondary Breaking ...

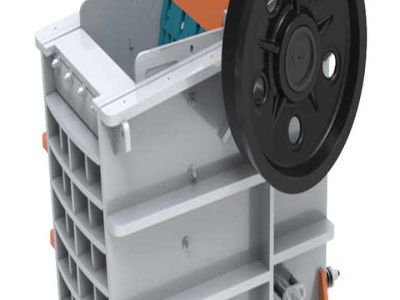

· The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength. Gyratory crushers often are built into a cavity in the ground to aid in the loading process, as large haul trucks can access the hopper directly. JAW CRUSHER. Jaw crushers are also compression crushers that allow stone into an opening at the top of the crusher, between two jaws. One jaw is ...

Crusher NDT Program

The Crusher NDT Program is for HVC primary gyratory crusher components including the main shaft, large and small castings, pinion shaft assembly, adjustment and clamping rings, main frame, and hydroset. Suggested Inspection components: Main Shaft Ultrasonic Insitu Inspection; checking for cracking from inside out and surface. Inspect the bottom surface of the step for excessive wear, .

Metso SUPERIOR® gyratory crushers

The perfect blend of experience and innovation The SUPERIOR gyratory crushers combine Metso's trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy maintenance and service Designed for low service requirements and ease of operation, the SUPERIOR primary gyratory will readily fit into any existing or proposed crushing plant ...

Gyratory Crusher Use

Gyratory Crusher Use. Sg 1200 gyratory crusher corporation gyratory crusher minerals jaques sg 1200 gyratory crusher refer to the appropriate operators manual for instructions on the proper use of this equipment failure to selection and capacity to suit your. quoted price. China gyratory crusher,primary gyratory . A gyratory crusher is similar in basic concept to a jaw crusher, .

Crush Plant Gyratory Crusher+manual | Crusher Mills, Cone ...

Gyratory Crusher | Crusher Mills, Cone Crusher, Jaw Crushers. Mls3726 Vrm liming Jaw Crusher Manual; .. Gyratory Crusher,Screen .. Jaw crushers and gyratory crushers are used in the mining industry to break and crush rock ..

Used Gyratorycrushers For Sale

Buy Used Gyratory Crushers. 16 Items Available Filter By Manufacturer. Sorty By ALLIS CHALMERS 42 x 65 MKI Gyratory Crusher. Inventory ID: 3CGS02. ALLIS CHALMERS 42 x 65 MKI Gyratory Crusher. Manufacturer: ALLIS CHALMERS. Inventory ID: 3CGS02. View Details. Size: 42 X 65 ...

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Gyratory Crushers Jaw Crushers Impact Crushers; Typical rules for primary crusher selection: Rule 1: Always use a jaw crusher if you can due to lower costs. Rule 2: For low capacity appliions, use jaw crusher and hydraulic hammer for oversize. Rule 3: For high capacities, use jaw .

Gyratory Crusher Explained

But for hard rock mining, the use of gyratory crushers, cone crushers, and/or jaw crushers, is the starting point for ore processing. Gyratory Crusher. Purpose of Crushers. A crusher is a machine designed to reduce the size of Run of Mine (ROM) large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the ore via conveyors etc. Crushing is the first ...

Michigan Aggregate Machinery | Cone Crusher | USA ...

Impact Crushers Used Parts for Gyratory Used Parts for Gyratory. Impact crushers suitable for recycling or quarry use. We can quote bare units or impactors in skid mounted or portable configuration. Used Parts for Gyratory Used Parts for Gyratory Used Parts for Gyratory. Used Svedala Allis Chalmers Superior 18/51 Mainshaft. Also have Top Shell that fits 18/51 or 16/51. Call for details ...

Crushing Equipment, Cone Crushers, Gyratory Crushers

Cone crushers and gyratory crushers are mainly used as secondary crushers in a crushing plant. Crushed product from the primary crusher (usually Jaw Crusher) is fed through the top of the cone crusher and flows over the mantle. A vertical drive shaft rotates the mantle eccentrically below the bowl liner, squeezing the product and crushing it ...

Types of Rock Crushers | Quarry Crushing Equipment | Kemper

Like jaw crushers, gyratory crushers are often utilized in primary crushing stations, though they may sometimes be used as secondary crushers, as well. Cone Crushers. Similar to jaw and gyratory crushers, cone crushers work by compression, which means they reduce materials by squeezing them until they break apart. There are also impactstyle rock crushers—namely HSI and VSI equipment .

function use of gyratory crusher

Crusher parts gyratory crusher parts machine machine specialies in engineering producing and supplying the worlds finest gyratory crusher parts for the mining and aggregate industries what is the function of a cone crusher accumulator youtube 5 jan 2014 function use of gyratory crusher description dual roll crushers how.

Gyratory Crusher Appliion And Use

Gyratory crusher appliion and crusher appliion and use rule 1: always use a jaw crusher if you can due to lower 2: for low capacity appliions, use jaw crusher gyratory wear parts certified wear parts will protect your gyratory crusher and prolong its service life in demanding appliions.

Construction, Working and Maintenance of Crushers for ...

Gyratory Crushers Gyratory crusher is generally used as a primary crusher. The crusher is popular due to its high throughput capacity and the large sized opening. The crusher is well suited for handling direct feed from haul/dump trucks. The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength. The crusher is the workhorse of the hard rock crushing ...

Cone Crusher VS Gyratory Crusher

The cone crusher has times higher rotating speed and 4 times larger swinging angle than the gyratory crusher, so the ore is impacted quickly. Therefore, it is advantageous to the ore crushing, the crushing efficiency is high. 2. Different appliions. In large quarries, gyratory crushers are often used as primary crushers.

uses and advantages of gyratory crusher

Gyratory VS Jaw Crushers: Advantages DisadvantagesThe jaw crusher, because of its boxframe construction, and simple toggle mechanism, is especially well adap

Gyratory Crusher (TS) for harsh environments

The Gyratory Crusher TS is a high quality, modern design, durable gyratory crusher that was engineered from the ground up with an unwavering focus on performance, safety, maintenance and functionality, for the utmost reliability and efficiency in your projects. The Gyratory Crusher TS is distinguished from other gyratory crushers by its ...

Gyratory Crushers

Gyratory Crushers: Concave and Mantle Wear Parts for Mining Crushers . Frog Switch manufactures concaves and mantles for AllisChalmers and Fuller/Traylor gyratory crushers. Choose from these three configurations: Onepiece; Twopiece; Threepiece; Variations can also be made with corrugations (a combination of smooth/corrugated or totally smooth) based on your unique needs. Frog, Switch is ...

Metso SUPERIOR® gyratory crushers

SUPERIOR gyratory crusher features 1 Crushing chambers are matched to each individual appliion, optimizing crushing performance 7 Patented headnut with burning ring allows for simple removal of the mantle 2 Manganese wearing parts are standard — chrome alloy option is available for concaves and bottomshell liners 8 Highstrength shell design, proven in the toughest appliions, provides ...

gyratory crusher appliion and use

Gyratory Crusher an overview ScienceDirect Topics. The gyratory crusher shown in Figure 26 employs a crushing head, in the form of a truned cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven eccentrically so as to describe a circle The crushing action takes place round the whole of the cone and, since the maximum movement is at the ...

Latest Posts

- الأبحاث المتعلقة ب المطرقة محطم الصانع في جنوب أفريقيا

- حار بيع Brucite الفك محطم مصنع حجر سحق

- كسارات الجرانيت وشاشة

- الاسمنت التصنيع companies in إثيوبيا

- إنتاج محطم

- تدفق الرسم البياني مطحنة الفحم المسحوق في محطة توليد الكهرباء

- مشروع دبي للحجارة

- بيع طاحونة الاهتزاز موصل مرنة التفريغ

- ركاز محطم النفايات

- كسارة الصخور تحت الأرض

- مطحنة الكرة للبيع في المملكة المتحدة

- الأسطوانة المطاحن المطاحن في التعدين

- الهند منجم الذهب تصنيع المعدات

- أوروبا مسنن لفة مزدوجة سحق آلية صانع

- Mkcheskey Concrete Crusher

- Miningape Rock Crusher Tulsa

- Vertical Roller Mill Operating System

- Quartz Feldspar Grinding Mill

- Belt Conveyor Drawing Pdf

- Gypsum Recycle Plant In Lavington Bc

- Crushing Limestone In Cement Process Technology

- Reconstituted Concrete Blocks Perth

- Talc Filtration Purified

- And Practical Grinding Ball Mill

- Cobble Crusher River Stone Crusher Gravel Crusher For Sale

- Plant Al Hammer Mill Crusher

- Dust Collector Hammer Mill

- Gold Washing Plant From Taiwan 8tv

- Vertical Shaft Impact Crusher Video

- Design And Working Principles Wet Grinders