Burners For High Temperature Shaft Kiln

Cement Rotary Kiln

Cement rotary kilns refer to cement rotary calcining kilns (sometimes called rotary furnaces). It is a pyroprocessing device used to heat materials to high temperatures in a continuous process. The kiln body is a cylinder vessel with a certain degree of tilt to the horizontal level. Raw materials are fed into the vessel from the upper end and ...

Kiln Refractory/ Industrial Kiln Refractory Insulation ...

Burning zone is loed in the high temperature chemical atmosphere, kiln fuel temperature is ℃ along with molten liquid. Refractory is generally coated by raw materials and along with the turning of kiln body, so kiln lining is always spalling.

German Kiln Technology: Technical ceramics

Type of products to sinter. German Kiln Technology (GKT) is a major supplier of sintering lines and kilns for producing all kinds of technical ceramics, such as: Struktur und Elektronikkeramik. LTCC Keramik. Katalysatoren und Filter für die Automobil und chemische Industrie. Medizinkeramik. Hochreine Al 2 O 3 und Zirkonoxidprodukte.

Shaft furnace for burning loose material

In the course of final operation, hightemperature roasting of semifinished item thus obtained is performed; roasting includes slow heating of crucible by preset schedule to temperature of 850950 C continued for 46 hours at rate of deg./min; then heating is intensified at rate of 1015 deg./min till melting point is obtained, thus ...

Vertical Shaft Kiln Vs Rotary Kiln

Aug 29, 2020 · Kilns to produce cement are almost equally old. Now cement kilns can be divided mainly into 2 types: vertical shaft kiln and rotary kiln. The vertical kiln is the older type and its origin dates back to the 5 th century AC. Rotary kilns were first used in 1880. Around the 20 th century, they replaced vertical shaft kilns almost everywhere.

pfr/twinshaft/rd vanguard kiln

Twin shaft PFR lime kiln, the PFR lime kiln, tunnel kiln, types of kiln, Pfr kiln. Handan metallurgical engineering and Research Co., Ltd is the present domestic top professional in lime kiln industry integrating of engineering design, equipment fabriion, installation, operation, training, commissioning, and startup. So far, we have contracted around 20 sets high efficiency and energy ...

High Alumina CastablePT. INDOFURNACE

high alumina refractory castable Appliion: It can be used as lining and burners for various heat treatment furnaces, blast furnaces, heating furnaces, electric furnace tapping slot,high temperature zone of lime shaft kiln, Rotary kiln head, power plant boiler and other industrial furnace lining.

Serge Jorget and David Kotrys, Fives FCB, France, discuss ...

discuss rotary kiln maintenance offerings. Cement kilns: evolutions and induced problems The rotary kiln has been used for cement production for about a century and has become the only burning technology, with the less efficient and polluting shaft kilns largely disappeared. The kiln can be considered the heart of the cement plant.

gas burner for industrial use in shaft lime kiln

Annular Shaft Kiln For Lime Burning With Kiln Deep. ay 01 2008 Annular shaft kiln for lime burning with kiln gas recirculation Due to excessively high temperatures in the bustion chambers at optimal air excess ratio the flame must be cooled with a greater amount of relatively cold secondary air. more Annular Shaft Kiln For Lime Burning With ...

Improving the operating effectiveness of the shaft kilns ...

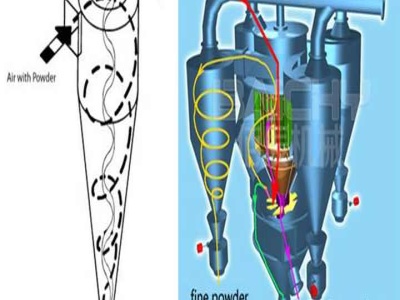

This paper attempts to develop a design of gas burner for providing uniform hightemperature firing of refractory material in shaft kilns. On the model the influence of the following factors on the processes of mass exchange and the character of the gasdynamics was studied: the ratio of the diamters of the gas and air orifices of tubeintube type burners and their absolute values with a ...

Rotary Kiln – IspatGuru

Dec 26, 2019 · The rotary kiln also competes with the shaft furnace in the production of sintered magnesite and dolomite. As in limestone calcination, the rotary kiln offers the advantage of handling charge material of finer size with a broad size range and can also handle throughputs at high calcination temperatures.

Furnace Lining Refractories for Sale

Such as heating furnace, various heat treatment furnace electric furnace cover shaft kiln, rotary kiln, blast furnace tapping channel, ladle, hot metal ladle, etc. The selfflowing low cement refractory castables are mainly used as thin linings and linings for hightemperature refractory components with .

High Temperature Air Combustion Technology (HTAC ...

Henan Dajia Mining Machinery Co., Ltd mainly produce and install rotary kiln projects, shaft kiln, regenerative furnace plants, contact with us if need any kind of mining machines. Henan Dajia Mining Machinery Co., Ltd. Tel: +. Fax: +. Mob: +. Web:

BURNERS AND CONTROLS

Typically, depending on the kiln or furnace back pressure, gas pressure and burner head design, the venturi throat area should be approx. 4050% of the total burner port area. Mismatching may result in a decrease in mixture velocity producing inadequate burning or at worst "flash back".

Optimizing the preheating zone in a tunnel kiln

In many tunnel kilns, in the higher temperature range (600 – 800 °C), highvelocity burners are installed for temperature homogenization. Energy input is not usually necessary for the process and, in isolated cases, it can even be detrimental. With the use of hightemperature circulating fans, a much more energyefficient solution is achieved.

Formulas kiln

Jul 22, 2010 · Rotary Kiln power input calculation : W x bd x td x N x F x 1 = rd W = Total vertical load on all roller shaft bearing,lb bd = roller shaft bearing diameter, inches Note : This is Frictional rd = roller diameter, inches 1 Horse Power td = tire or riding rind diameter, inches N = rpm of Kiln shell P = Coefficient or friction of ...

What are the influencing factors of calcination of ...

In actual operation, in order to better control the calcination of limestone in the shaft kiln, to achieve high quality, high yield, stable low consumption, it is necessary to Strict control. 1. Limestone calcination temperature Limestone calcination rate has a great relationship with temperature.

Annular shaft kiln for lime burning with kiln gas ...

May 01, 2008 · The high temperature heat needed for lime burning in a kiln H proc is the total sum of heat needed for the chemical reaction, calcination (decomposition of CaCO 3 to CaO and CO 2), which is indied by column 4, and heat consumed for radiation losses and .

Burner Systems for Rotary Kilns Brochure

Design features include mechanical or steam atomization of oil and sturdy, rugged construction for high temperature duty. Burner systems range from preheat to 300 MBtu/hr. (315 GJ/hr.). Engineered and custom designed valve trains for safe, efficient, reliable combustion are provided Valve drains are prepiped and pretested and shipped as an ...

Manufacturers of Tower Melting Furnaces | shaft furnace ...

Silcarb now boasts of a range of highdensity MoSi2 heater range, a wide customercentric Kiln Furniture production centre, and a brand new facility for the manufacture of fine Technical Ceramics including Nitrides, Carbides and Titanates. Silcarb has been supplying a .

Vertical Shaft Kiln Vs Rotary Kiln by Reitz India Limited ...

Oct 27, 2020 · Now cement kilns can be divided mainly into 2 types: vertical shaft kiln and rotary kiln. The vertical kiln is the older type and its origin dates back to the 5th century AC. Rotary kilns were ...

Requirements of Refractory Materials for Lime Rotary Kiln ...

Lime rotary kiln is a dynamic kiln, and there are many requirements for refractory materials for the lining. For example, it is resistant to high temperatures and can be chemically stable at high temperatures for a long time. Reburning is small, with high mechanical strength, compact structure, and low porosity.

Energy and exergy analysis of an annular shaft kiln with ...

Request PDF | On Jun 1, 2017, Wenjie Rong and others published Energy and exergy analysis of an annular shaft kiln with opposite burners | Find, read and .

Latest Posts

- صغيرة الحجم كسارة الفك الصانع الهندي

- جزءا لا يتجزأ من القمامة محطم

- الأبحاث المتعلقة ب هيدروليكي ملموسة محطم

- فيك هيل مخروط محطم

- تأثير محطم مرنة

- كسارات المحمولة ذروة المحدودة

- أسعار المحاجر الألمانية

- طين الطين في تعدين الذهب

- كامل معدات سحق وغربلة خام الحديد

- معدات لغسل خام التنتالوم

- سحق النبات تغيير غربال فرع

- الكرة مطحنة PPT

- الاسمنت طحن مطحنة متوسطة التحميل

- مخروط محطم لتجهيز خام الحديد

- غرق نوع الغذاء الطاحن

- Milling Machine Verified

- Chemical Device Of Bau Ite Kosovo

- Coal Primary Crusher Manufacturer

- Ball Crusher Coal Crushing Equipment

- Ore Mining Equipment Manufacturers

- Jaw Crusher Relative Siitne Mx

- Stone Crusher Philippines Manufacturer Stone Crusher Machine

- Line Crusher And Mill

- Sanding Machine Movable Price

- Sugar Mill Supplier In Lithuania

- Used Komplet Crusher For Sale

- Mobile Sand Crusher Price

- Cr Vi In Chromite Concentrate

- Coarse Crusher Series

- How To Melt Granite