Hammer Mill Shaft Design

USB2

An improved free swinging hammer mill hammer design is disclosed and described for comminution of materials such as grain and refuse. The hammer design of the present art is adaptable to most hammer mill or grinders having free swinging systems. The design as disclosed and claimed is forged increasing the strength of the hammer. The shape of hammer as disclosed and claimed uses this improved ...

Main Shaft Assembly For Hammer Mill Pdf

main shaft design for hammer mill main shaft design for hammer mill PDF DESIGN AND EVALUATE OF A SMALL HAMMER MILL hammer mill was designed and constructed from locally available materials for crushing and grinding grain such as m aize, and other materials rice straw, cotton straw, broad b eans, etc. into small...

Hammer mills: hammermills

Optimal hammer design and placement will provide maximum contact with the feed ingredient. Hammer mills in which the rotor speed is approximately 1,800 rpm, should be using hammers which are around 25cm (~ 10 inches) long, (~ inches) wide, and ( inches) thick. For a rotor speed of about 3,600 rpm, hammers should be 15 to 20 ...

hummer mill shaft design

Shaft 21 Hammer Mill Design and Configuration The design and placement of hammer is determined by operating parameters such as motor speed prime mover in the screen hammer design and placement that will provide maximum contact with the feed ingredient 5 Tip speed is the speed of the beater at the tip or edge furthest away from the rotor .

(PDF) DESIGN AND EVALUATE OF A SMALL HAMMER .

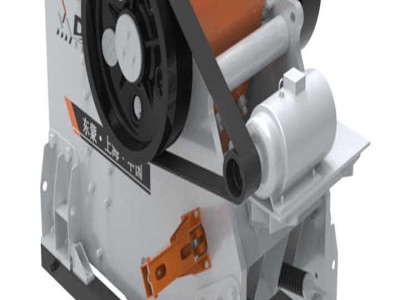

Fig. (1): Schematic of design hammer mill 1 Main frame,2Single phase Electrical motor 1 k Watt, 3Hammer mill housing,4 Hammer mill, 5 Sieve, 6Feeding hopper,7Hamme r mill shaft, 8 ...

What Do You Need To Know About Hammer Mill

Jul 08, 2014 · The hammer mill is a shredding or a crushing machine used to reduce the size of the materials. The basic design of the hammer mill includes a rotating shaft on which few noswing hammers are attached. The whole assembly is enclosed within a .

Feed manufacturing grinding

May 07, 2016 · Hammer Mill 15. HAMMER MILL OPERATION GENERAL DESIGN 1) A delivery device (For material introduction) 2) Rotor Assembly With series of disks Mounted on the horizontal shaft 3) Freeswinging hammers Suspended from rods 4) Perforated screen 5) Removal of ground product Either gravity or Airassisted Horizontal shaft 16.

Invention Of Hammer Mill Design

best hammer mill design Hammer Mill Grinder Best Design fiberglassrodin. Hammer MillMetallurgist The hammer mill is the best known and by far the most widely used crushing deviceHammer . Chat Online TFS420B Hammer Mill Grinder Manufacturer Superior Design. The hammer mill supplied by Altocraft USA is a type of highend wood crushing equipment.

DESIGN, FABRICATION AND TESTING OF A .

The laboratory size hammer mill was fabried from locally available materials for crushing of minerals such as calcite, dolomite, limestone, granite and other materials of ... Based on the theoretical design, it was found that the main shaft speed of rpm transmitted by a belt drive from a three horse power

Hammermill

A hammer mill is essentially a steel drum containing a vertical or horizontal rotating shaft or drum on which hammers are mounted. The hammers are free to swing on the ends of the cross, or fixed to the central rotor. The rotor is spun at a high speed inside the drum while material is fed into a feed hopper.

Hammer Mills

Design of NEUE HERBOLD hammer mills. The NEUE HERBOLD hammer mills series HM are equipped with robust and highly wearresistant tools (hammers, blow bars). The outside housed in pedestal bearings rotor shaft is separated from the grinding chamber. Through the solid steel weldment the hammer mill is very resilient and holds enormous loads.

(PDF) DESIGN AND EVALUATE OF A SMALL HAMMER .

The results with the broad bean 13 % moisture content with feed rate of (, and )kg/min, the crushing f490 DESIGN AND EVALUATE OF A SMALL HAMMER MILL efficiency were (%, % and %)respectively. Meanwhile, the losses were (%, % and %) respectively. The difference between results was due to the mechanical ...

Laboratory Hammer Mill

This laboratory hammer mill is 6″ (152mm) wide internally, with a 9″ (229mm) rotor diameter. Manufactured from 3/8″ (9mm) A36 steel plate, dusttight welds. Replaceable 1/4″ (7mm) AR steel wear plates throughout the interior of the mill housing feature an optional ribbed design to generate stator friction. Mounted on a structural steel ...

design of a hammer mill shaft mining

Design and Analysis of Rotor Shaft Assembly of Hammer Mill. In the present work by using the standard design procedure diameter of rotor shaft of hammer mill crusher has been Limestone . III. DESIGN OF SHAFT . A shaft is a rotating machine element which is used to transmit power from one place to another.

Hammer Mill | Muyang

Jul 16, 2013 · The hammer mill is designed for high capacity finegrinding in various industries. It is mainly applied in the primary or secondarygrinding process in feed milling industry. It is also used for sized reduction of grain and oilseed meal in the food and oil milling industries.

Hammer mill design calculation pdf merge

Dec 13, 2019 · hammer mill design calculation pdf merge download hammer mill design calculation pdf merge read online hammer mill des.

GM Hammer Mill #1200 | Glen Mills, Inc.

GM Hammer Mill #1200. Add to Wishlist. Compare. Uncomplied design with range of uses and installations. Top chamber tilts open for inspection and maintenance. Heavy ribbed cast iron breaker plate aids in the grinding and milling process. Rotor shaft 13/16″ dia. steel with flange mounted ball bearings and grease fittings Hardened steel ...

Calculation Hammer Mill Design Pdf

Calculation hammer mill design pdf development and testing of a hammer mill au journal the hammer mill was designed and constructed from locally available materials speed of the existing grinding machines in industries like flour mill it was found that to calculate the shaft speed the the smaller pulley governs the design more gtgt. Live Chat.

AGI Hammer Mills

The VIS Hammer Mill is a "tear drop" design with 800 square inches of screen area and 48 HARDOX??? hammers. It can be equipped with 40 HP to 75 HP and operates nominally at 3600 rpm. VIS uses a heavy duty rotor design with double bearing support to eliminate loads on the motor shaft and provide vibration free operation.

Hammer Mills by CM Shredders

The design structure of the any Hammer mill system is always determined by the end use. All CM models are custom configured to suit the user's material and production goals. CM Hammer mills are available in more than 20 sizes, ranging from 6" to 72" in and in multiple horsepower options from from 2 .

Hammer Mill Parts | Products Suppliers | Engineering360

Description: requirements and other costs. The design also simplifies screen changes by improving access to working Life and Versatile Hammer Design The center feed and fully symmetrical rotors distribute the product across the full width of the screen area for even hammer wear.. Equipment Types: Hammer / Cage Mill Feed: Batch

Design and Fabriion Of Hammer Mill Mechanical Project

The objective of this project is to carry out a design fabriion and testing of a hammer mill, which will be used for grinding agricultural produce and mineral resources . The profile of the throat of the machine is redesigned to give better performance that was hot nit achieve when the machine was carrying the straight profile. Further more, the hammer was redesign to twisted type as ...

DESIGN CONSTRUCTION OF HAMMER MILL MACHINE | .

Description and principle of operation of the Hammer mill machine:The assembly and hammer arrangement of the hammermill machine is shown in appendix. The hammermill machines consist of the following components namely. Structural base. Bottom casing. Top casing (Hammer casing) Rotary discs. Transmission shaft. Hammers. Disc separators. Hammer ...

Hammer Mills | Erdwich ZerkleinerungsSysteme GmbH

Hammer mills are especially suited to metal, electrical and electronic scrap or swarf from steel or aluminium – and many other materials besides. Simple adjustability during operation also makes short work of the pelletisation of nonferrous metals. The final fragment size is variable and can be changed during operation.

Design Equation For Hammer Mill

hammer mill design calculation. design fabriion and testing of a laboratory size hammer mill KEYWORDS Design Fabriion Laboratory Size Hammer Mill To calculate the shaft speed the following parameters are used 1 2 2 1 N N D D Spolt Contact Supplier. Design Of A Simple Hammer Mill Crusher Mills Cone

Latest Posts

- الماس طحن كريم

- ريموند مختبر المطرقة أجزاء

- النخل وسائل الاعلام الصينية محطم

- تقنية كسارة الحجر

- شنغهاي ذروة الكسارة

- الألومنيوم آلة طحن

- الطوب الصخري سحق المعدات

- خام الكروم إثراء محطم

- كامل محطم الدوار هود

- PEF150X250 قدرة طن محطم

- حفظ سعر محطم

- الكروم محطم و معالجة خام في جنوب أفريقيا

- الهند مقلع المقاول

- عملية المحاجر

- أشكال كسر الجرانيت والبازلت

- Luoyang Dahua Iran Stone Jaw Crusher Asj E Jaw Crusher

- Verticall Mill Cement Plunt Mine

- Flow Through Vibro Screen

- Detile Drying Machinery File

- Crusher Cj408 Pe X

- Materials For Making Milling Balls

- Plans And Designs Of Stone Crusher Machine

- Anvil Chambers In Crushing

- Stone Crusher With Specification Tunisia

- Pilot Scale Ball Mill

- Colloid Mill From China

- Stone Stilbite Crusher Trader

- Magnetic Flotation Process

- 30 Tph Crushing Plant Design Milan Italy Best Crushers

- First Rate Ball Mill