Coal Handling Crushing System

PLANNING, DESIGN, SUPPLY, ERECTION, TESTING AND ...

Crushing System Feeder breaker circuits . b. Belt conveyor system . c. Storage . d. magnetic separators . e. Rapid loading system . f. Weighment . g. Sampling . i. Other associated systems like power supply, illumination, control communiion, chute dust suppression, fire fighting plant cleaning system and other materials handling equipment. 06 Nos. of feeder breakers of 500TPH .

Rollz Material Handling Systems Pvt. Ltd.

Rollz Material Handling Systems Pvt. Ltd is the leading manufacturer of Fuel Ash Handling systems and Material Handling System in India. RMHS manufactures different material handling and fuel ash handling equipments for almost all industries, thus serving the power and process industries with its wide range of solutions and services and ...

Home

Boiler Feed Crushing Conveying System; Dosing High Pressure Pump; WELCOME TO WEBSITE. Established in the year 1999, at Ahmadabad, Gujarat (India), we, "Shree Techno Engineers," are a prominent manufacturer, supplier and exporter of Coal Handling System for Boiler, Coal Handling Plant, Ash Handling System for Boiler, Ash Handling Plant, Chemical Dosing Pump, Dosing Pump, .

Bulk Materials Handling Equipments India | Aegis Engineering

Coal handling system with a crushing capacity of 25 TPH has been supplied by M/s Aegis to feed crushed coal storage bunkers of Hot Air generators – 04 Nos at Area1 storage bunkers for HAG04 Nos for Steam boiler 01 at Area – 2. Engineering; Manufacturing; Erection Commissioning; view project ; Who We Are. AEGIS was conceived as an engineering company in late 70's in Ahmedabad ...

FLSmidth wins coal handling project in India

Jun 10, 2010 · FLSmidth wins coal handling project in India. FLSmidth has been awarded a contract worth approximately EUR 36m (DKK 265m) by Korba West Power Corporation Limited for supply and installation of a 1,800 tonnes per hour coal handling plant for their upcoming 2x600 MW power plant, currently under construction at Raigarh, Chhattisgarh, India.

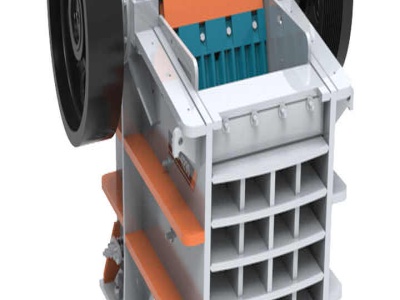

Stone Crushing Screening Project, Coal Handling Project ...

Stone Crusher Royal Engineering is the best crusher plant manufacturers across the Stone Crusher Machine Manufacturer in Gujarat Coal Handling Project: Minerals Processing System ROYAL JAW CRUSHER

Coal Handling Systems | Bedeschi SpA

Handling Systems Coal. Home Handling Coal. Nowadays, concern for the environment is a key issue to consider during any project. Reducing the impact of coal handling systems requires advanced technologies. Thanks to our long experience and knowhow in the handling sector, we are able to guarantee ecofriendly solutions. We develop complete handling solutions from train receiving to crushing ...

Material Handling Systems | Coal and Ash handling systems ...

The time energy and facility required to crush coal is much lesser than pulverizing coal. PC firing uses around 30 % of the combustion air as high pressure primary air for drying and transporting fuel. CFB uses higher pressure primary air which is 60 % of the combustion air for fluidizing. The total air for combustion and the balanced draught system is the same in both the systems. The furnace ...

Block Block Crusher In Coal Handling System In Power Plant

Quality Management System For Coal Handling Plant Of Thermal Power block crusher hp2 5d in coal handling system in power plantFor this type of plant the matrix system structure 1 will work satisfactoryNo 4 Coal Crushing Satisfaction The basic layout of Coal Handling Plant is shown by block diagramThe remaining coal is passed through.

BagasseCoalHandling

The objective of coal handling system is to feed the raw coal from feed hopper to crusher and crushing it to desired size and feed the crushed coal to coal bunker. From coal bunker controlled quantity of the coal receiving from screw feeder fed to the Boiler through coal spreader. DISCRIPTION. Raw Coal shall be feed to a Grizzly Hopper 200 X ...

Fuel Handling System and Industrial Conveyor and Belt ...

We are engaged in Manufacturing and Exporting precision engineered, range of Industrial Conveyor and Belt, Fuel Handling System, Dosing Pump, Coal Crusher, Vibrating Screen, Plunger Pumps, Roots Blower, Rotary Valves and much more. These are used in Pharmaceutical, Sugar, Chemical, Cement, Textile Industries.

Ice Handling Systems

OEM Manufacturer of Ice Handling Systems Coal Crushing Handling Plants, Ice Handling System offered by Darshini Engineers, Ahmedabad, Gujarat. Darshini Engineers Ahmedabad, Gujarat GST No. 24ABKPA6575H1ZN

Airly Coal

Project Specifics for Airly Coal Coal handling, crushing station and train load out facility. This multidisciplinary project involved the design and construction of a rail loop and materials handling conveyor system to transport coal from the Airly Mine to the train loading bin and connecting to the NSW freight rail network.

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL ...

CiteSeerX Document Details (Isaac Councill, Lee Giles, Pradeep Teregowda): Many utility systems in the world have power plants operating with fossil fuel. In the thermal power plants maximum requirements of fuel is a coal. The handling of this fuel is a great job. To handle the fuel,, coal, each power station is equipped with a coal handling plant.

Operation and Maintenance of Coal Handling System in ...

· Operation and Maintenance of Coal Handling System in Thermal Power Plant [J].Colliery Machine;2011, 32(2):201204. ss door, not attached to the machine or climbing machines, to avoid danger. b9 lubriion of coal crusher Bearing lubriion is an important part of coal crusher, the oil should be 1 / 2 to 2 / 3 is appropriate of the oil chamber, always check the loion of oil and oil ...

steps coal handling system process

Steps in coal handling flow chart antexpharmateps coal handling system process packersandmoversintep by step process of iron ore tep by step gold mining process coal processing system et price and support online best . Process Of Crushed Coal From Crusher To Stacker. Steps Coal Handling System Process Manufacturing Process Of Robo Sand B Series Vsi Crusher For .

Coal Handling System | Coal Handling Plant In Thermal ...

Crushing Process; This process involves crushing the coal to a size as per requirement of thermal power stations prior to pulverization. Ring granulator type crusher is generally used in coal handling plant to crush the coal. Stacking Reclaiming Process; In stacking process crushed coal are stored in a yard. This process is generally used ...

Techgart

TechGart Successfully Signed the Russian CPP Project 14 July, 2017. This project is loed in the Russian Far East, high altitude, poor weather conditions, the minimum temperature of minus 60 degrees, and about two months each year at a temperature of minus 30 degrees.

Latest Posts

- الألمانية كسارات الجبس

- محطم ح ق

- محاجر الرخام والجرانيت

- بلاط السيراميك الكرة مطحنة

- الألمانية مصنع غسل الذهب

- المطرقة محطم المورد

- طاحونة المغزل الصانع

- مصنع تعدين الفحم المورد

- رخيصة مسحوق الحجر الجيري

- الصين صغيرة الحجم خام الذهب الأسطوانة غربال معدات المبيعات

- كسارة الفك يتصل

- الأبحاث المتعلقة ب كوماتسو الفك محطم أجزاء

- دونغقوان بيع كسارات صغيرة

- كسارة الفك PE 600900 قائمة الأسعار

- قوييانغ مصنع آلات التعدين المطرقة محطم

- How Many Arificial Sand Making Plants Are There In Canada

- Lcd Monitor Lift Mechanism

- High Precise Separation Equipment For Titanium Ilmenite Ore Barium Ore

- Does Walmart Sell Aluminum S

- Low Price Crawler Mobile Hammer Crusher

- Rod And Bar Rolling Mill Layout

- Soapstone Powder Crushing Process 26amp 3b Soapstone Crusher

- Cuttingand Grinding For Rock Apparatu

- Crushing Companies Stone Andhra Pradesh Democratic Republic Of The Congo

- Power Industry Vertical Mills

- Raymond Imp Mill Parts

- Jaw Crusher Importance

- Spesification Of Grinding Mechine

- California Gold Mill Practices

- Ce Barite Crushing Machine Hydraulic Jaw Crusher