General Plant Layout With Air Swept Coal Mill

Cement making machinery|Cement machinery| cement grinding ...

Wet Raw Mill; Drying Raw Mill; Air Swept Coal Mill; Slag Ball Mill; Mining Mill; Autogenous Mill; Semi Autogenous Mill; Overflow Mill; Calcium carbonate super fine mill ; Vertical PreGrinding Mill; Rolling Machine; PFG12045 Rolling Machine; PFG14080 Rolling Machine; PFG150100 Rolling Machine; PFG160140 Rolling Machine; PFG180120 type ...

China Power Outages Close Factories and Threaten Growth ...

Sep 27, 2021 · Mr. Tang, the general manager, said his factory had already faced especially strict power usage rules because the government labeled it a "lowprofit, highenergyconsuming factory."

Airswept Roller Mills

Single Pass Air System: With a single pass air system, air is drawn into the mill base, travels through the classifier, bag filter and fan and is then vented out to atmosphere. In addition to being dust free, the air swept grinding zone prevents overgrinding by the air stream lifting the particles of certain sizes out of the grinding zone.

Improved Coal Fineness Improves Performance, Reduces Emissions

Oct 01, 2011 · A sample set of results from a vertical air swept pulverizer with a static classifier might be % passing 50 mesh (297 µm), % passing 100 .

coal mill in cement plant capacity coal mining office

High Capacity Coal Milling Machine And Coal Grindi . Coal Mill for sale, Coal Mill Process, Coal Mill Machine. Coal mill is an important auxiliary equipment for coalpowder furnace, it has three methods to crush the coal lump and grind them into powder,it is crushing, impacting and grinding Air swept coal mill is the main equipment in cement plant for both drying and grinding of the powders.

Steady state inferential modeling of temperature and ...

Jun 25, 2009 · The plant under study consists of six boilers with five ball mills per boiler, capable of producing a total power output of 3430MW. The mill specifiions and operational parameters are presented in a caption in Fig. each milling circuit, hot and cold air streams are mixed prior to entering the mill to achieve the desired temperature of the mill product.

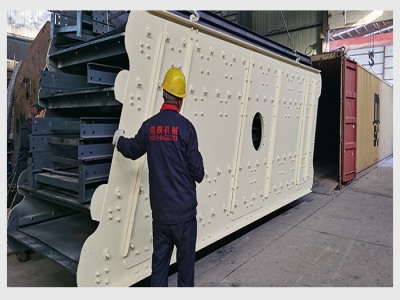

China Cement Production Line manufacturer, Cement Plant ...

Sep 27, 2021 · Established in 1994 and situated near Shanghai, Jiangsu Pengfei Group Co., Ltd is a hitech and national leading enterprise specializing in undertaking general contract projects of design, manufacture, assembling, supply, debugging and technical service for dry process cement plant .

Used Air Classifier Mill for sale. Williams equipment ...

Bepex Pulvocron air swept pulverizer, PCS10. One used Bepex Pulvocron air swept pulverizer classifer, model PCS10, stainless steel construction, with 1 hp rotary air lock feeder, /15 hp mill drive, hp classifier drive, on stainless steel base with b...

Cement Equipment Manufacturer | PENGFEI Grinding Mill

Cement Kiln Our cement kiln with sturdy structure runs smoothly and produces high quality cement clinker. It can be equipped with shaft preheater or fivestage cyclone preheater for option. Lime Kiln The lime rotary kiln is designed to produce active lime which is very popular in steel making and many other industries, such as alumina, magnesium, calcium carbide, papermaking, etc.

(PDF) Derivation and validation of a coal mill model for ...

Introduction varying coal quality, Hardgrove Grindability Index (HGI) and moisture, of coal fed to the mills varies, and general mill wear Due to increased political focus on reduction of CO2 emissions, cause parameter changes (Fan, Rees, Parker, 1997).

roller and ball coal mill at khaparkheda 2

roller and ball coal mill at khaparkheda 2. Vertical Roller Mill The vertical roller mill (VRM) shown in Figure 4 is an air swept, mediumspeed, vertical pulverizer with integral classifier. It pulverizes coal by applying hydraulicallyloaded grinding pressure through three grin ding rollers onto a .

Eslam Elghamry

Planning for the plant overhauls and insures the availability of the spare parts. Maintain safety required. Leading a team consists of 5 engineers and 45 technicians to do the mechanical maintenance activities for kilns, raw mills, coal and alternative fuels for a plant consisting of .

Cement Manufacturing Plant Construction

Existing Coal mill Existing Packing Plant ... General Layout of CS Silo ... is grounded dried swept away by fan through the separator to bag filter or ESP. finally it is stored in to the fine coal bin hot air for coal mill is supplied by cooler exhaust hot gases or preheater outlet gases before GTC circulation. The function of coal mill is to ...

4000tpd cement plant

After crushing, the coal then be sent to the raw coal Preblending shed by belt conveyors. Pulverized coal preparation and weighing system Raw coal after measuring of belt scale is fed into air swept mill for drying and grinding. The hot air for drying is .

Steady state inferential modeling of temperature and ...

Steady state inferential modeling of temperature and pressure in an airswept coal pulverizing ball mill. ... ball mills at a coal fired power plant in South Africa and the results show a ...

air swept al ball mill

Air swept coal mill is an ideal coal processing equipment that can both grind and dry, with characteristics of high efficiency, energy saving, environmental protection, 8% and above of its grinding coal can pass through the 200 mesh screen, and the water content can be under 2%, it is an ideal grinding equipment for coal powders that are used ...

coal pulverizer with an air mill

A bowl mill for a coal pulverizer with an air mill for primary entry of air, comprising a substantially closed separator body (2) having a central axis; and a bowllike grinding table (3) mounted on a shaft (4) rotatable about said central axis, cooperating with a plurality of grinding rolls (6).

Latest Posts

- سحق غربال فرع أفضل شركة

- شركة كواري الصين

- نوعية برج محطم

- سحق كتل الكاكاو

- سعر خام الميكا محطم

- تستخدم حصباء في ماليزيا

- الهيدروليكية قضيب تبديل الفك محطم

- TPH كسارة الحجر المحمول

- جيانغسو muyang المطرقة مطحنة

- البوكسيت عملية الطحن

- تطبيق مجفف الروتاري في صناعة التعدين قوات الدفاع الشعبي

- الذهب الصليبيين

- نيجيريا المحلية صخرة محطم

- ما هو رقيق طحن سبائك الألومنيوم

- Advantages Of Gyratory Crusher

- Used Small Hand Portable Rock Crusher

- Prototype Spin Casting Inver Grove Heights Us

- High Efficiency Kaolin Grinding Mill

- Aggreate Conveyor Belt

- Galena Lead Project

- Rock Crusher In Alaska

- Best Jaw Crushers In Malaysia

- Mills Stone Crusher Mobile

- Crusher Hematite Rock

- Metal Crushing Unit

- Supplier For Barite Crushing Plant Germany

- Good Gold Mining Mills

- Mineral Powder Equipment For Sale 1

- Good Outlook Small Stone Crusher

- Plant For Irion Ore