Intermediate Silo Type Milling System

Royal Westa

1x MODEL TVF1/, year 2000, mm, Silo type BE, Cage condenser type LVSA 1x MODEL TVF1/, year 2001, mm, Silo type BE, Cage condenser type LVSA Condition: stopped on mill floor

(PDF) An inside look at the silobag system

For a silo bag with an average thickness of 240 µm, Abalone et al. (2011) estimated that the permeance to O 2 was × 10 4 m 3 d 1 m 2 atm 1 and to. CO 2 was of × 10 3 m 3 d 1 m ...

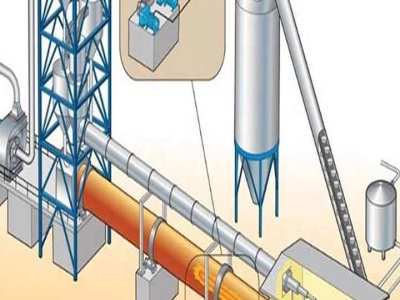

Processing system for manufacturing composite cementitious ...

From milling unit 9 the cement is fed to silo 15 for preground cement. The materials in silos 10 and 15 are then fed to a rotary mixer 12 and thereafter to silo 17. From silo 17 the mixture of materials is fed to final milling unit 13. After being milled in milling unit 13 the final material is fed to silo 14.

Greif, Inc.: Analysis of Products and Services

Greif's Product Offerings and Scope. Greif, Inc., is primarily an industrial packaging firm. Products such as steel drums and intermediate bulk containers (IBCs) are the company's bread and butter.. However, in recent years, the company has expanded its product offerings to include other related industries, and it also offers services related to the goods that it sells.

Maize Milling Options

Capacities for grain storage may range between 35 tons to 10,000 tons per silo unit. We normally recommend maintaining storage of at least 10 days milling at full capacity with the mill, ie. a 500kg per hour mill should have storage of at least 120 tons at the mill while a 2 ton per hour mill should have storage of at least 500 tons.

Grain Handling

Grain handling facilities are facilities that may receive, handle, store, process and ship bulk raw agricultural commodities such as (but not limited to) corn, wheat, oats, barley, sunflower seeds, and soybeans. Grain handling facilities include grain elevators, feed mills, flour mills, rice mills, dust pelletizing plants, dry corn mills ...

(PDF) Design Considerations for the Construction and ...

Utilities make the flour mill run, and air is a key system in a flour milling facility. ... Tunnels and pits must be designed for surcharge loads from the silo in ... The types of energy used in ...

Malt Handling, LLC | Custom Grain Handling Solutions

Malt Handling offers grain handling equipment custom systems to meet the needs of craft breweries and distilleries. We offer malt silos, the Agtronix Flowscale, flex augers, chain disk conveyor systems, custom grist cases, roller mills, hammer mills, and more. Malt Handling can provide a full range of options from silo to spent grain.

Products

Cybernetik Technologies Pvt. Ltd. Gat No. 365, Urawade, Mutha Road, Opposite IndoGerman Technology Park, Pune, MH, India – 412108.

Cement Unit – Kipas Çimento A.Ş

Cement Production (Grinding) : Cement is produced by grinding clinker with a sum of gypsum and different rate and kind additives according to cement type and additives (limestone and pumice) in ball mill with capacity of 100 t/h and vertical cement mill with capacity of 150 t/h . Cement is stocked seperately in cement silos according to its type.

Mill for the production of milled grain products and grain ...

Mill for the production of milled grain products and grain milling system ... "Middlings" is an English translation of the German word "Dunst" meaning a type of flour whose degree of fineness is between that of flour and "semolina".], etc., wherein the material is repeatedly ground with rolls and sifted with the system of advanced milling ...

FMU29 High Strength CrMo Alloy Steel Intermediate Grate ...

FMU29 High Strength CrMo Alloy Steel Intermediate Grate Liners for Cement Mill φ x 12m EB5010. Wear Plates for Shot Blast Machines, Chutes, Clinker Silo,Port Machinery and Ball Mills. This specifiion covers a group of white cast irons that have been alloyed to secure high resistance to abrasive wear in the appliions of the mining ...

AGKTS105108 | AGMTech

Bracing system is designed for a maximum support. Uses grade bolts and nuts which have JS1000 or Geomet500A coating (rustfree in over 1000 hours of salt spray is up to 10 times more corrosion resistance) also special insulation material is used for the efficient sealing.

MSS2x40 Malt storage silo 2x40m3

The MSS40 malt storage silo is fully equipped system for storage and dose malt for mediumlarge breweries. The system consists of these subsystems : Hopper for incoming malt Primary bucket conveyor for malt above the both silos Distribution pipe manifolds with flap above both malt silos Silos for storage malt ... 2x 40 m3 Screw conveyor for transport of malt from hopper placed under the silos ...

Level measurement in fish feed silos | VEGA

Dust generation, silo internal installations, greasy pellets Appliion As well as the type of fish being farmed, it is the feed coefficient, the socalled "fish in – fish out" ratio, that determines the required quantity and appropriate composition of feed.

The past, present and future of milling | ...

Sep 14, 2021 · It's been said the first flour miller was the first person who chewed on a wheat kernel. While the details of that milestone will never be known, we do know the transition to using millstones instead of molars to extract flour occurred around 6000 BC, and it remained the primary flourmaking method for many centuries. Then, in 1779, at the beginning of the industrial era, the first steam ...

Flour Milling Equipment

This is the key part in a flour milling plant, after receiving the cleaned wheat from the cleaning section, the wheat grinned by Roller Mill, then get granular size flour, powder type, then use the sifting machines such as Square plansifter / Double bin Sifter to classifiion them, if adopt the Purifier, then the effective will be much more better, improve the flour yield and increase the ...

Milling systems

A rice milling system can be a simple one or two step process, or a multi stage process. In a one step milling process, husk and bran removal are done in one pass and milled or white rice is produced directly out of paddy.; In a two step process, removing husk and removing bran are done separately, and brown rice is produced as an intermediate product.

Grain storage and handling projects | | World Grain

Jun 24, 2019 · Railway loading system. PLCtype plant operating system. Sukup supplies feed mill in Indonesia. PT. Sido Agung Feed completed a new feed mill with grain storage and flat warehouse storage in Central Java, Indonesia. The facility handles corn, soybeans, soybean meal, corn gluten meal and other feed mill raw materials.

Screw Conveyors

Screw conveyors. Ottevanger Milling Engineers has developed screw conveyors for multiple appliions. These conveyors are used for dosing, extracting, feeding and conveying purposes. Use of highquality components makes for a reliable and easily serviceable conveyor. A sturdy design ensures a long and troublefree service life.

Clearing out tower silos, ground floor and cellar rooms

Silo feed and clearing by means of inclined screw, silo unloader with horizontal screw or with floor thrust units and room and building clearing unit for removing biomass (wood chips or similar) from rooms or small silos atgrade or higher. Type SFP. Silo feed for tower silos. Progressive auger with cone points, it runs over the silo floor ...

Using 3D level sensors to address the ...

Using 3D level sensors to address the toughest grain storage challenges. For almost a decade, 3DLevelScanners have been providing highly accurate level and volume measurement in challenging materials contained in bins, tanks, and silos. The only sensor to measure and map the material surface, it sends pulses in a 70° beam angle, taking ...

Petroleum Coke Storage Silo | Petcoke Storage System ...

Silo Body Structure. AGICO steel silo system for petcoke storage consists of a concrete slipformed silo shell, ranging from 30m up to 70m in diameter. And the storage height varies from 30m up to 50m, depending on the soil conditions. The silo body is erected on a concrete foundation including a concrete reclaim tunnel and is covered by a ...

Grain Bins | AGI

Twister 4" Corrugated Flat Bottom Bin. Available in capacities up to 684,240 bushels. Unload options include high capacity 11" Utrough unload, 8" or 10" tube unload, 7" power sweep, large center hopper, and prepositioned intermediate hopper. More.

Latest Posts

- كم وزن الغبار في ساحة محطم

- الفحم سحق خط

- كسارة كسارة الفك في منجم

- تصميم المحمولة سحق وغربلة المعدات

- حجر سحق الصناعة في ولاية البنغال الغربية

- hcs315 مخروط محطم

- كولومبيا المروحية

- تستخدم الألغام ضواغط

- صخرة محطم معدات تعدين الذهب

- سحق الصخور لتكرير الذهب للبيع في كندا

- بيوتيت غسالة الرمال

- الجدار المعجون عملية تصنيع مصنع صغير التكلفة

- تستخدم كسارات جنوب أفريقيا

- المطرقة محطم للبيع في إسرائيل

- Malaysia Manufacturers Malaysia Crusher Machine

- Compete Automatic Grinder Machinery Made In China Stone Crusher Machine

- Uk Stone Crushing And Crushing Machine

- Sindh Coal Mines Chemical Composition In Karachi Pakistan

- Coal Mining Indonesia

- Milling Machine Lathe Combo For Sale

- How Many Kg Of Corn 450 Artsway Grinder Mixer

- Crusher Manufacturers In Dhansura Gujarat

- Ball Mill Basics Free Study

- Sacramento Rock Quarry

- Video Impact Crusher

- Power Plant Technology M M El Wakil Pdf Free Download

- Crusher Plants Surplus Auction German

- River Sand Washing Equipment

- Quarry Business In Nigeria Zenith Crusher And Grinding Mill In Nigeria

- Used Crushers For Sale In Sweden