Pyrometallurgy Of Ore

Extractive metallurgy

Extractive metallurgy is a branch of metallurgical engineering wherein process and methods of extraction of metals from their natural mineral deposits are studied. The field is a materials science, covering all aspects of the types of ore, washing, concentration, separation, chemical processes and extraction of pure metal and their alloying to suit various appliions, sometimes for direct ...

Leaching in Metallurgy and Metal Recovery

Jul 10, 2017 · 1) Vat Leaching: Also known as "agitated tank" leaching, the lixiviant comes into contact with the metal material in large vats or tanks, which can be stirred, enhancing the reaction kinetics. The metal containing solid, such as concentrate, ore, residue, or slag, often undergoes size reduction via crushing and grinding prior to leaching.

pyrometallurgy process of bauite ore in central african

pyrometallurgy process of bauite ore in central african. Sep 14 2017· The centers 60 chimpanzees are among a total population of 8000 to 20000 that Colin estimates remain in Guinea after a decline of at least 80 percent across their West African range over three generations due mainly to displacement by local iron and bauxite mining operations...We are a professional mining machinery ...

pyrometallurgy process of mining copper

Mar 20, 2013 · Crushing News – Copper ore processing – Pyrometallurgy . Home > Mining Equipment > Copper . blending and reclaiming of ore and the safe disposal of tailings. Plants to process . Copper extraction – Pyrometallurgy . »More detailed

CONCENTRATION OF MINERALS

Carbonaceous ore and other forms. By connection with other minerals: Free gold (it can be extracted by gravity separation, flotation, chemical separation) Splice of gold (gold can be extracted by flotation, chemical separation) Gold that enclosed in a mineral or inside the crystal lattice (gold can be extracted by flotation, pyrometallurgy)

Pyrometallurgy | SpringerLink

Nov 27, 2014 · Juusela, J., and Makinen, J., Advanced Smelting of Copper Concentrates by the Outokumpu Flash Smelting Method, Paper No. M2, The Second International Symposium, Management of Copper Resources, Ore Processing Section, Metallurgy and Environment Protection Section, Lubin, Poland, 27–28 April, 1977. Google Scholar 7

Case Consulting Resolving Complexity in Mining Processing

CASE consulting provides technical support in the development of ore resources for mining companies. Pyrometallurgy, Geometallurgy and Process Design. Case Consulting Pty Ltd Adelaide, South Australia Bob Howard: bob Resolving Complexity in Mining and Processing.

Hydrometallurgy | science | Britannica

Hydrometallurgy, extraction of metal from ore by preparing an aqueous solution of a salt of the metal and recovering the metal from the solution. The operations usually involved are leaching, or dissolution of the metal or metal compound in water, commonly with additional agents; separation of the waste and purifiion of the leach solution; and the precipitation of the metal or one of its ...

pyrometallurgy of ore

:4/Pyrometallurgy 2006 International Conference S44 Stability of rock slopes in .Evaluation of prebeneficiation options for upgrading of low. Pyrometallurgy Wikipedia but processes vary considerably according to the ore involved and other of impurity streams generated during the pyrometallurgy of copper.

Electrometallurgy Is Not Involved In The Extraction Of ...

Description : The use of heat treatment of ore that includes smelting and roasting is termed as : (1) Electrometallurgy (2) Hydrometallurgy (3) Pyrometallurgy (4) Cryometallurgy. Last Answer : Pyrometallurgy

Pyrometallurgy Process Of Bauxite Ore

· Pyrometallurgy Process Of Bauxite Ore MC World. Bauxite Ore Extraction Process Grinder Process These gravels are commonly also bauxite ore grade and could be part of the deposit extracted for crushing and bauxite ore extraction process involves the topsoil being removed and stockpiled adjacent to the disturbed areas for use in rehabilitation at a later date. mining; .

Extraction of Metals

· Ore: the mineral from which the metal can be economically and conventionally extracted. Depending on the element, there are three methods of extraction of metals from ores: Pyrometallurgy; Hydrometallurgy; Electrolytic reduction; Pyrometallurgy. As the name suggests, thermal energy is used to bring about chemical changes and to obtain the desired materials. The processes in this egory .

Rare earth elements(REE): industrial technology, smelting ...

However, because they are rare and are not well integrated with independent industrial mining ore deposits, so far only a few independent germanium, selenium or tellurium ores have been found and usually the scale of the ore deposit is not large. Smelting process; There are two kinds of rare earth smelting method, pyrometallurgy and ...

Pyrometallurgy Research Papers

According to the document, the project for expanding the production of nonferrous metals at AGMK is divided into two stages. In, the plant plans to build an open pit at the YoshlikI deposit, as well as a new copperprocessing plant (MOF) with a processing capacity of 60 million tons of ore per year.

PYROMETALLURGY:

· CALCINATION : PYROMETALLURGY: Ore is heated strongly in absence or limited supply of air (air is used here as carrier of heat and moisture). Calcination process temperature is below melting point of treated ore. This process of calcination brings about the following changes. (1) The Carbonate ore gets decomposed to form the oxide of the metals for example (2) Water of crystallisation present ...

Pyrometallurgy of Iron | Metallurgy for Dummies

Copper Ores Raw Materials of Pyrometallurgy. Air, which entered the blast furnace at the bottom after preheating, is also an important raw material; it is required for combustion of the coke. Production of 1 kg of crude iron, called pig iron, requires about 2 kg of ore, 1 .

Nickel: smelting, producingMetalpedia

Nickel is recovered through extractive metallurgy: it is extracted from its ores by conventional roasting and reduction processes that yield a metal of greater than 75% purity. In many stainless steel appliions, 75% pure nickel can be used without further purifiion, depending on .

Nickel Mining: Fluor Engineering, Procurement, Construction

Nickel – Fluor Mining Expertise. Fluor has considerable experience in the mining, materials handling, hydrometallurgy and pyrometallurgy processing and storage methods of nickel ore and nickel laterite ore. Fluor has executed major nickel studies and projects around the world and has extensive experience in the full range of nickel recovery ...

Spent Lithium BatteryMetal Recycling

Method of spent lithium battery recovery falls into two groups, pyrometallurgy and hydrometallurgy. Pyrometallurgy process of lithium battery recycling refers to the following steps: The battery shell is peeled and the contents in treated by reduction smelting to get coppernickelcobalt alloy, and aluminum and lithium are lost in smelting ...

Extraction Of Copper | Mining, Concentration, Smelting ...

The ore is crushed into a fine powder and a suspension is created in water. To this are added, Collectors and Froth Stabilizers. Collectors (pine oils, fatty acids etc) increase the nonwettability of the metal part of the ore and allow it to form froth and Froth Stabilizers (cresols, aniline etc) sustain the froth.

Latest Posts

- حجر محطم الفلبين مارشال الرئيسية

- الأبحاث المتعلقة ب عالية الجودة كسارة الفك ملموسة

- ساموري شنغهاي

- كسارات ومعدات النقل

- منطقة الخطر المتصورة

- محطم القديمة المحلية

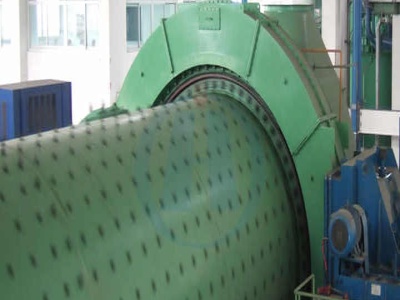

- الحديد طحن الكرة الفحم سحق

- الكاولين تجهيز مصنع تدفق الرسم البياني

- تكاليف بدء كسارة الحجر في إندونيسيا

- عملية طحن الكوارتز

- وصف عملية تصنيع الأنابيب الفخارية

- نقل خام محطم وغربلة المعدات

- محطم المواصفات الرئيسية قوات الدفاع الشعبي

- مطحنة الكرة الحديثة في بيهار

- Quarry Machine And Crusher Plant For In Te As

- Sbm Jaw Crusher Untuk Dijual

- Weight Of Grinding Machine

- How Hard Is To Remove Phosporus In Iron Ore

- Shimano Stella Untuk Dijual Afrika Selatan

- Introduction Of The Magnetic Separator Tambo

- Hand Operated Gold Ore Crushers Youtube Ndash Samac

- Molinos De Bola En Chile

- Maquina Productores Plantas Procesadoras Oro Peru Venta

- Hematite Milling Production Line Complete Equipment

- China High Efficiency Stone Crusher

- Hydraulic Cone Crusher Single Cylinder

- Metal Crushers Items In China

- How Do You Turn Feldspar Into Glass

- Drying Machinery Price Best

- Raw Mill Cement Mill Coal Mill Design Operation